Equipment for printing the surface of objects

A technology of objects and equipment, applied in printing, transfer materials, power transmission devices, etc., can solve problems such as large spacing and inaccurate printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

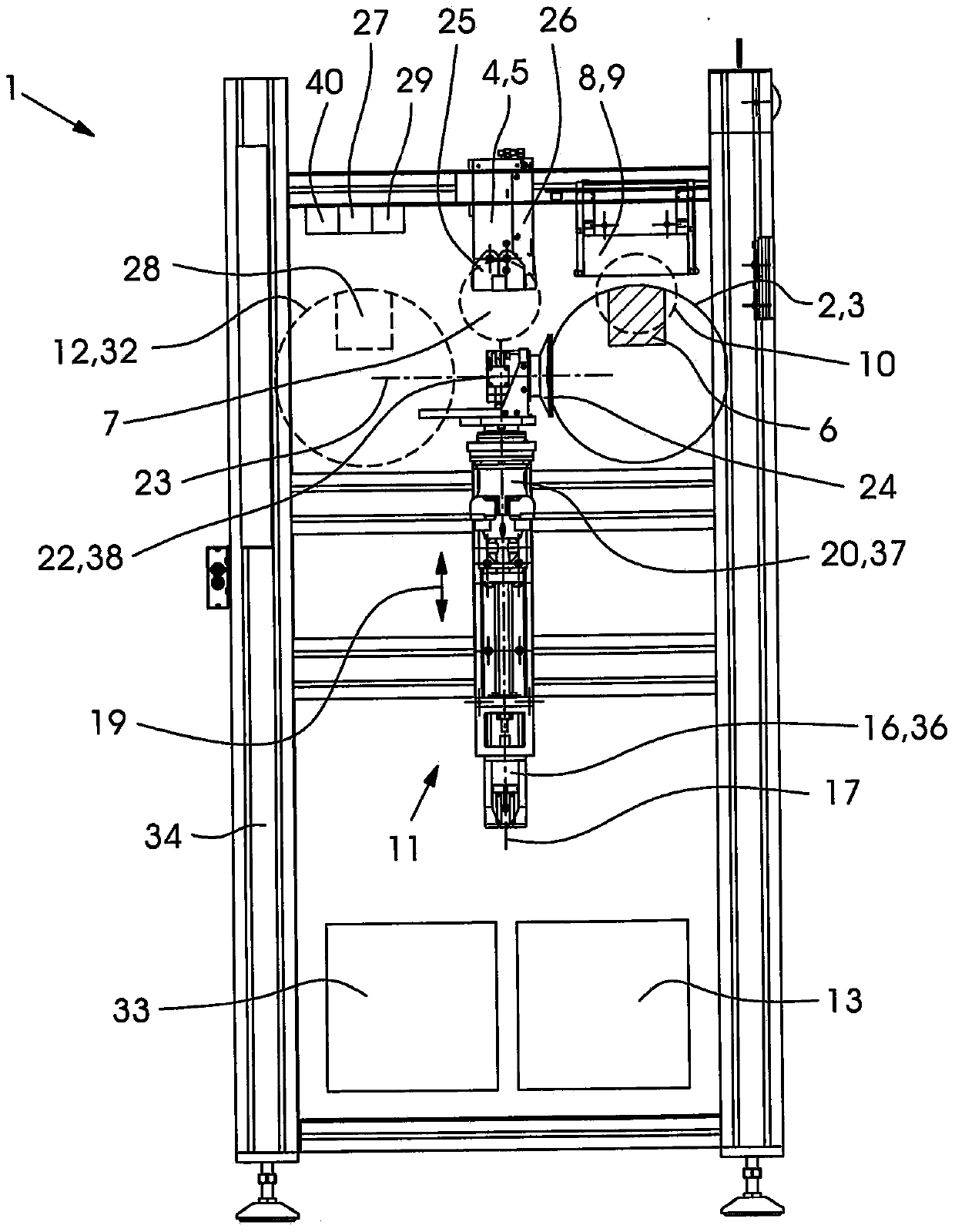

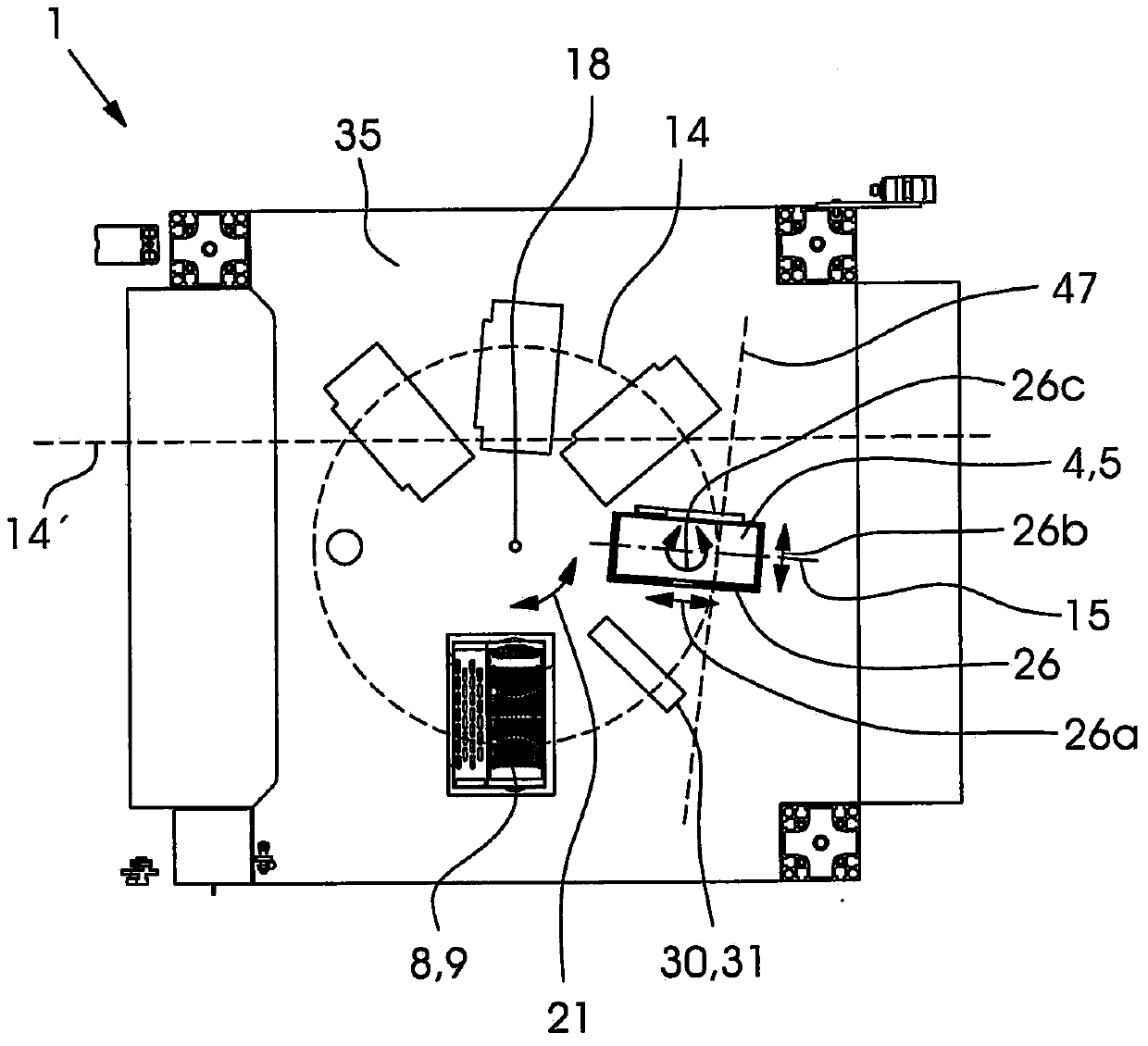

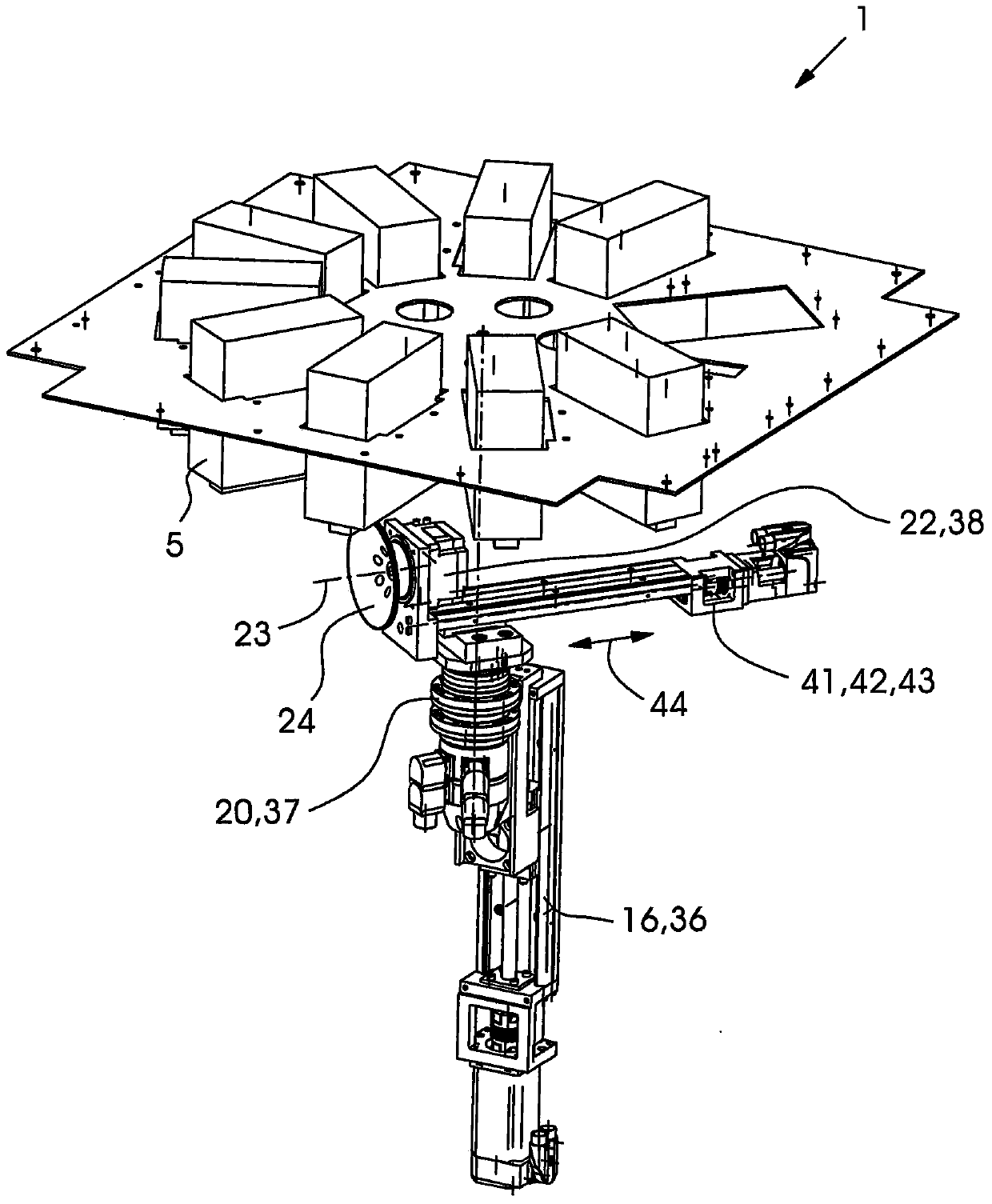

[0031] figure 1 A side view of a device 1 for individually printing a surface 3 of a three-dimensional moving object 2 that is curved in any direction is shown. The object may preferably have a flat, relief-formed or only slightly curved surface, such as Figure 4 and Figure 5 Indicated by number 2. The object may alternatively be a sphere. figure 2 A top view of the same device 1 is shown. In both figures, parts corresponding to each other are provided with the same reference numerals.

[0032] The device 1 comprises a printing unit 4 . The printing unit is arranged stationary in the upper region of the device. The printing unit comprises an inkjet printing head 5 . The print head is received in an orientation unit 26 of the printing unit. The orientation unit is arranged in an opening of a horizontally arranged plate 35 of a frame 34 of the device 1 . The plate has a plurality of openings whereby a plurality of print heads can be arranged. The opening and the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com