Aqueous ink jet ink compositions and uses

A technology of water-based inkjet ink and composition, applied in the direction of ink, application, household appliances, etc., can solve the problems of inkjet deterioration and unevenness, and achieve the effect of improving the durability of printed images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

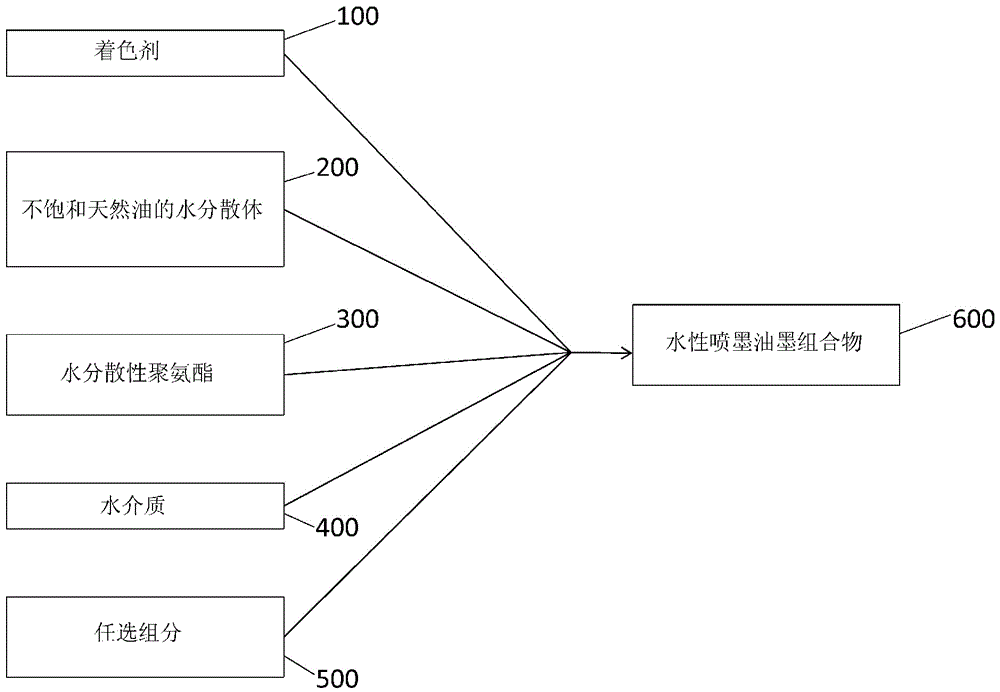

Method used

Image

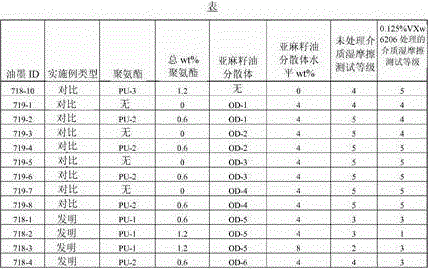

Examples

Embodiment

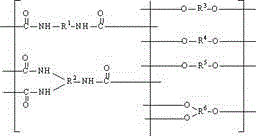

[0142] Preparation of unsaturated polyols for the preparation of polyurethanes

[0143] Unsaturated polyol - UP-1 A 250 mL 3-neck round bottom flask was charged with 25.8 g (245 mmol) diethanolamine and 0.25 g (1.22 mmol) sodium methoxide. The flask was equipped with a nitrogen inlet, a rubber septum and a stir bar. The reaction mixture was warmed to 105C to dissolve the sodium methoxide. To the reaction mixture was added 144.2 g (164 mmol) of linseed oil. The reaction temperature was raised to 110C and held for 5 hours. After cooling, 200 ml of dichloromethane (DCM) were added and the organics were washed twice with brine. The organic layer was then dried over sodium sulfate. The solvent was removed in vacuo to yield 150 g of a dark oil. Analysis by gradient polymer elution chromatography using an evaporative light scattering detector yielded approximately 40% monool amide ester, 40% diol amide ester, and 20% raw linseed oil.

[0144] Unsaturated Polyol - UP-2 A 250 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com