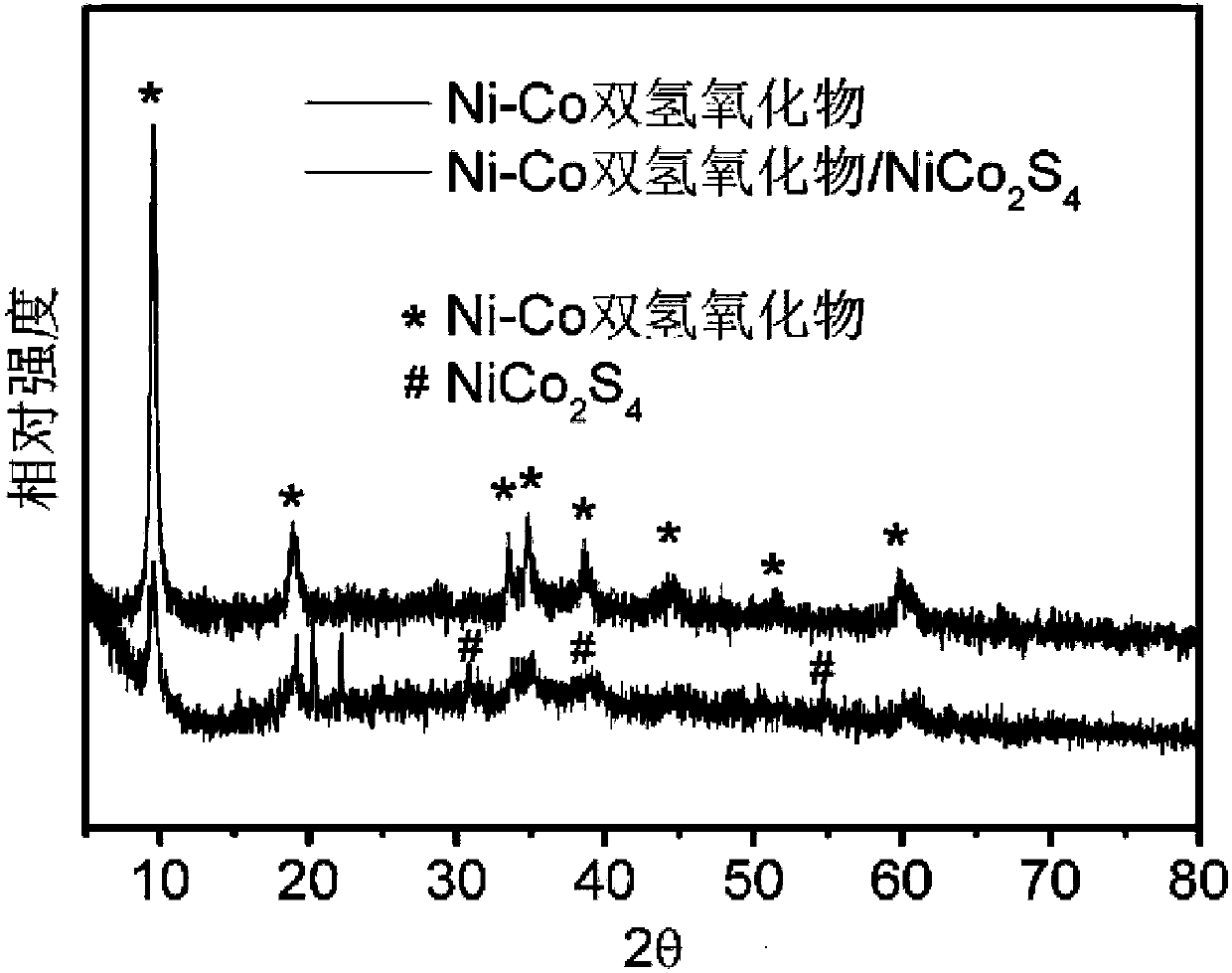

Nickel-cobalt double hydroxide/NiCo<2>S<4> composite nanomaterial, preparation method therefor, and application of composite nanomaterial as electrode material of supercapacitor

A technology of composite nanomaterials and double hydroxides, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., can solve the problems of low capacitance and energy density, achieve good electrochemical performance, growth The effect of large degree of freedom and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of nickel-cobalt double hydroxide / NiCo 2 S 4 A method for preparing a composite nanomaterial, comprising the steps of:

[0034] A, cobalt chloride hexahydrate, nickel chloride hexahydrate and hexamethylenetetramine are dissolved in 50mL water respectively, the concentration of cobalt salt in the solution is 0.08 mole / liter, the concentration of nickel salt is 0.04 mole / liter, six The concentration of methylenetetramine is 0.24 mol / liter, and a small piece of clean foam nickel (2cm×3cm) is immersed in the mixed solution, and reacted for 8 hours at 100°C. After cooling, take out the foam nickel sheet, wash it, dry, and prepare A nickel foam sheet loaded with nickel-cobalt double hydroxide nanosheets was obtained;

[0035] B, the foamed nickel sheet that step A is loaded with nickel-cobalt double hydroxide nanosheet is put into autoclave, adds 25mL 0.17 mol / liter thioacetamide solution in the still, with autoclave airtight, heating To 107°C, react for 10 hours. ...

Embodiment 2

[0039] A kind of nickel-cobalt double hydroxide / NiCo 2 S 4 The preparation method of nanocomposite material, comprises the following steps:

[0040] A. Dissolve cobalt nitrate hexahydrate, nickel nitrate hexahydrate and hexamethylenetetramine in 50mL water respectively, the concentration of cobalt salt in the solution is 0.02 mol / liter, the concentration of nickel salt is 0.01 mol / liter, hexamethylene The concentration of base tetramine is 0.06 mol / liter. A small piece of clean foamed nickel (2cm×3cm) is immersed in the mixed solution and reacted for 4 hours at 140°C. After cooling, the foamed nickel piece is taken out, washed and dried to obtain a loaded Nickel foam sheets with nickel-cobalt double hydroxide nanosheets;

[0041] B, the foamed nickel sheet that the nickel-cobalt double hydroxide nanosheet that step A makes is loaded is put in autoclave, adds 25mL 0.1 mol / liter thioacetamide solution in the still, with autoclave airtight, heating to 110°C, and reacted for 5 ...

Embodiment 3

[0043] A kind of nickel-cobalt double hydroxide / NiCo 2 S 4 The preparation method of nanocomposite material, comprises the following steps:

[0044] A. Dissolve cobalt acetate tetrahydrate, nickel acetate tetrahydrate and hexamethylenetetramine in 50mL of water respectively, the concentration of cobalt salt in the solution is 0.2 mole / liter, the concentration of nickel salt is 0.1 mole / liter, hexamethylene The concentration of base tetramine is 0.6 mol / liter. A small piece of clean foamed nickel (2cm×3cm) is immersed in the mixed solution and reacted for 10 hours at 100°C. After cooling, take out the foamed nickel piece, wash it, and dry it to obtain a load. Nickel foam sheets with nickel-cobalt double hydroxide nanosheets;

[0045] B. Put the foamed nickel sheets loaded with nickel-cobalt double hydroxide nanosheets prepared in step A into an autoclave, add 25 mL of 1 mol / liter sodium sulfide solution in the autoclave, and heat the autoclave to 105 °C, react for 10 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com