Determination method of difference operation maintenance strategy of electric power device

A technology for power equipment, operation and maintenance, applied in data processing applications, instruments, calculations, etc., can solve the problems of power equipment reliability (risk) and economy, etc., to improve equipment management level, easy to master, and operate Reasonable effect of maintenance strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

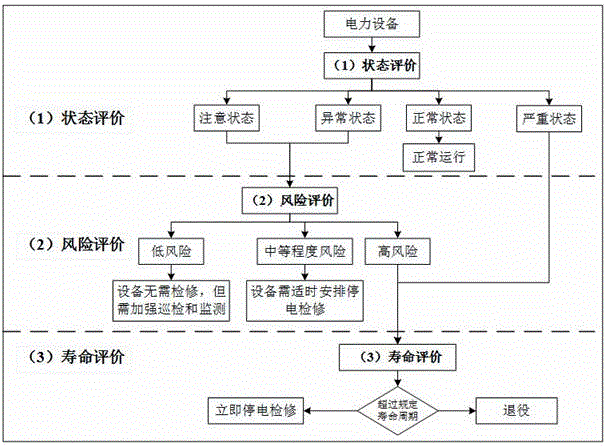

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is aimed at a 110kV transformer:

[0034] The chromatogram of the transformer oil is abnormal, the DC resistance of the 1st, 2nd, and 3rd gears on the 35kV side is abnormal, and other tests are normal.

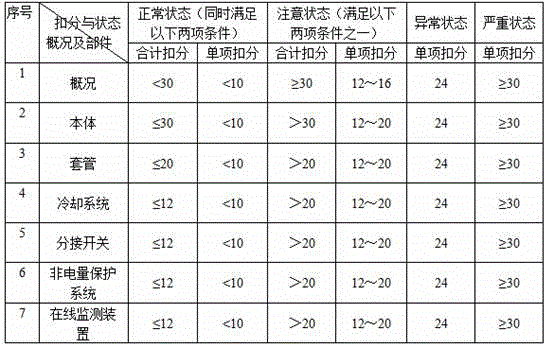

[0035] According to the method disclosed in the present invention: (1) firstly evaluate the state of the equipment, 30 points will be deducted for abnormal DC resistance, and according to the basis for determining the equipment level in Attached Table 1, the equipment is in an abnormal state and should be further passed (2) risk Assess in determining equipment operation and maintenance strategies.

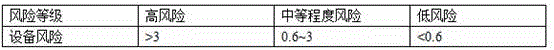

[0036] (2) Risk evaluation results: The asset evaluation of the equipment is 3, the asset loss degree is 2.45, and the failure probability is 0.650: the risk value is 4.78. Based on the basis for determining the equipment risk level in Attachment 2, the equipment is a high-risk equipment. Need to enter (3) life assessment process.

[0037] (3) The specified...

Embodiment 2

[0039] This embodiment is aimed at a 500kV transformer:

[0040] The transformer oil chromatogram is abnormal (acetylene), the iron core and iron yoke grounding circulation test of the main transformer is normal every month, the infrared temperature measurement of the main transformer is normal, and other routine tests are normal.

[0041] According to the method disclosed in the present invention: (1) firstly evaluate the state of the equipment, 16 points will be deducted for abnormal oil chromatograms, and according to the basis for determining the equipment level in Attached Table 1, the equipment is in a state of attention, and should be further determined through risk assessment Equipment operation and maintenance strategy.

[0042] (2) Risk evaluation results: the asset evaluation of the equipment is 8.25, the asset loss degree is 1.2, and the failure probability is 0.219: the risk value is 2.17. It belongs to medium-level risk equipment, which needs to be strengthened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com