Distributed dynamic process fault detection method based on mutual information

A fault detection and dynamic process technology, applied in program control, electrical program control, comprehensive factory control, etc., can solve problems such as ignoring useful information of complex dynamic characteristics of process data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

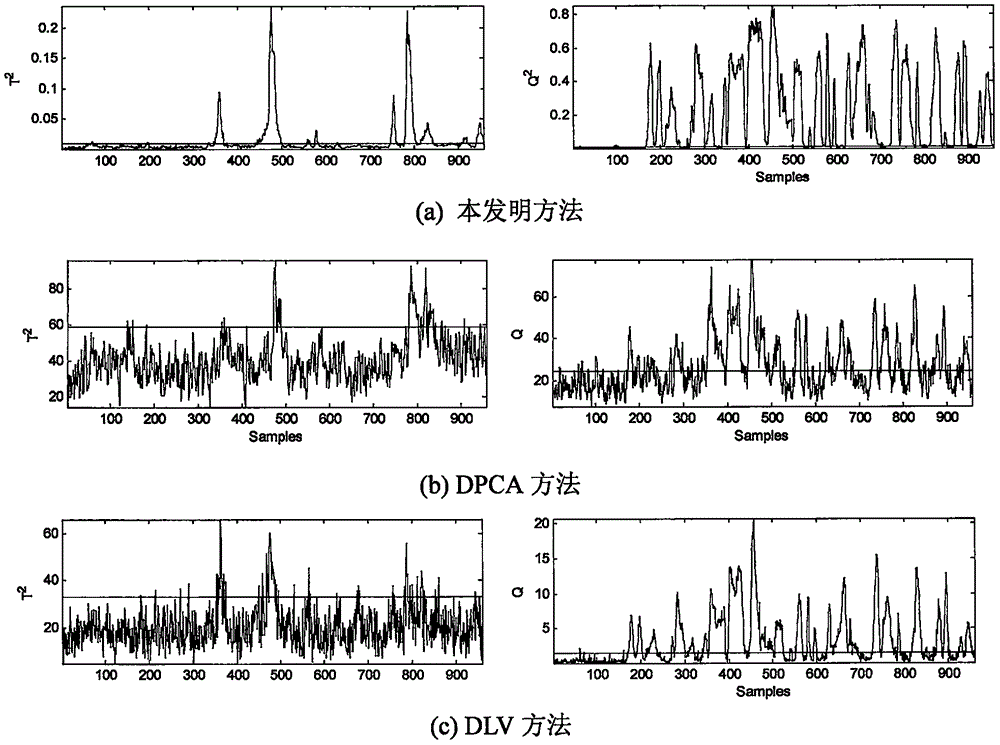

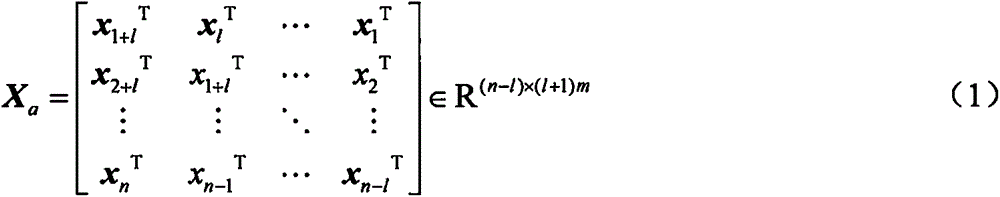

[0049] Such as figure 1 As shown, the present invention discloses a distributed dynamic process fault detection method based on mutual information. The method is aimed at the fault detection problem of modern industrial processes. First, the data collection system is used to collect data sets under normal operating conditions of the production process. Secondly, for each measurement variable of the process, the delay measurement values of the previous l moments are introduced to form an augmented matrix. Then, the matrix sub-block corresponding to each measured variable is selected by using mutual information, and a PCA fault detection model is established. Finally, online monitoring is performed on the new sampling data, that is, constructing with BI Q Monitor indicators and decide whether the current monitoring data is normal.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com