Coal water slurry gasification process DMC-PID multivariable control method

A DMC-PID, multi-variable control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of complex coupling relationship and affecting partial oxidation reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

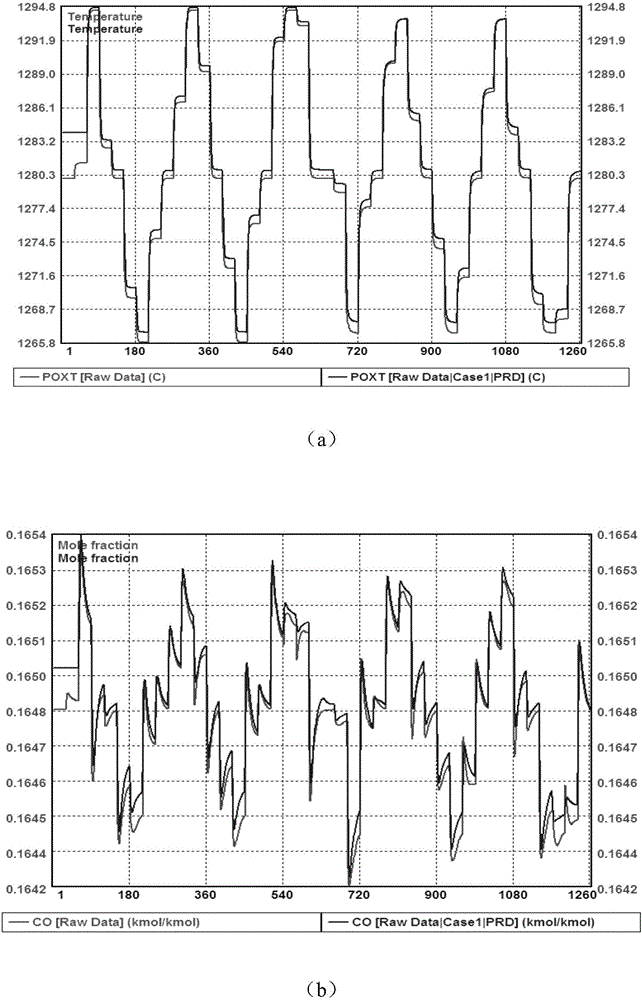

[0040] This embodiment is a DMC-PID multivariable control method for the coal-water slurry gasification process. The schematic diagram of the chilled coal-water slurry gasifier furnace body structure is as follows figure 1 As shown, the specific implementation steps of the DMC-PID multivariable control method for the coal-water slurry gasification process are as follows:

[0041] Step (1): Variable selection for the control system

[0042] The present invention selects the coal-water slurry flow rate and the oxygen flow rate as the operating variables, and selects the reactor temperature and the CO gas component yield as the controlled variables to construct a DMC-PID multivariable control method. The concentration of coal water slurry is selected as the test variable to verify the control method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com