Full-automatic high-frequency vibrating leveling machine for tunnel inverted arch

A leveling machine and fully automatic technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as the inability to guarantee the strength of the track bed, limited construction space, and damage to the track road surface, and achieve compactness by vibration and smooth operation. High efficiency, compactness and no bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

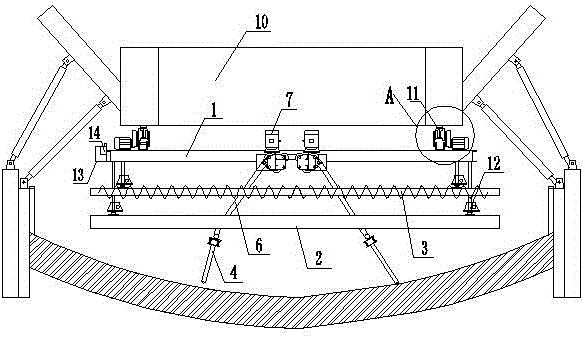

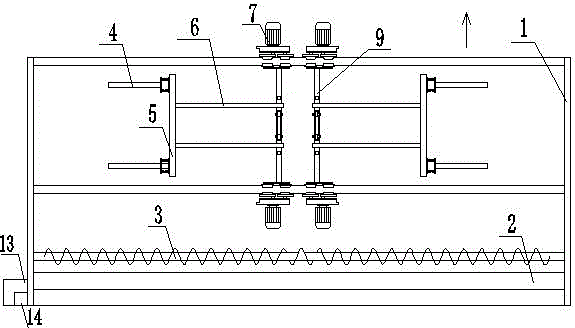

[0028] The invention discloses a full-automatic high-frequency vibrating and leveling machine for an inverted arch of a tunnel. The vibrating and leveling machine includes a longitudinal running track 11 arranged at the lower end of an inverted arch trestle 10, and a longitudinal running track 11 arranged at the lower end of the longitudinal walking track 11. The moving walking frame 1 is equipped with rollers driven by motors at both ends of the walking frame 1. According to the construction sequence of first vibrating, then distributing and finally lifting and leveling, a vibrating device and a cloth leveling device are arranged under the walking frame 1 in sequence. Such as figure 1 , figure 2 as shown, figure 2 The direction indicated by the middle arrow is the direction in which the machine runs in the present invention during construction. The vibrating device can move laterally along the track on the walking frame 1, so as to ensure sufficient vibrating of the concr...

Embodiment 2

[0033] This embodiment is improved on the basis of Embodiment 1. In this embodiment, the cloth leveling device uses a leveling vibrating plate 8 driven by a high-frequency vibrator. The leveling vibrating plate 8 covers a large area, and the leveling vibrating plate 8 is attached to the formwork 15 to push the concrete material to achieve the leveling effect during the traveling process. At the same time, the surface stones are hit into the concrete by vibration to level the concrete. The template 15 attached to the leveling vibrating plate 8 can also be made into different templates according to the design shape of the road surface. For example, if the surface of the road mattress needs to have a certain angle on both sides of the middle level, the formwork attached to the leveling vibrating plate 8 is made into a corresponding shape. Specifically, the leveling vibrating plate 8 attached to the formwork 15 is as follows: Figure 7 shown. Such a construction can meet the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com