Reinforced fiberglass geogrid for subgrade and manufacturing and construction methods thereof

A technology of glass fiber and geogrid, which is applied in the direction of roads, roads, road construction reinforcements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

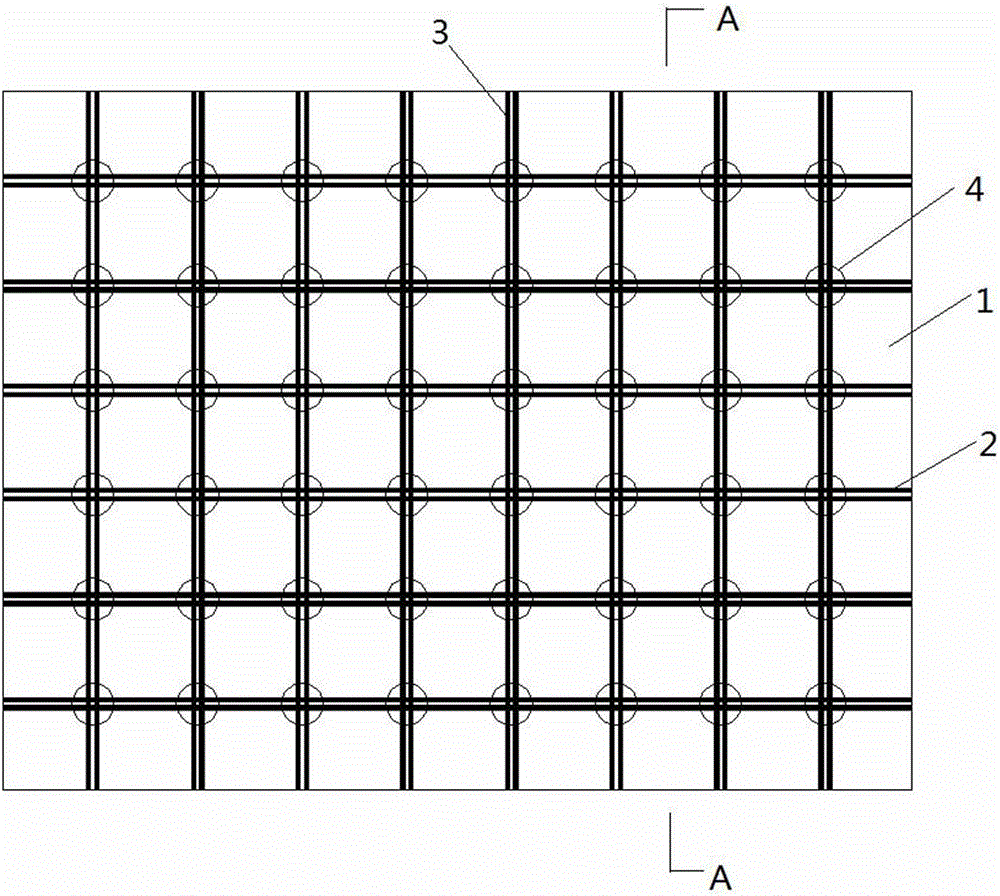

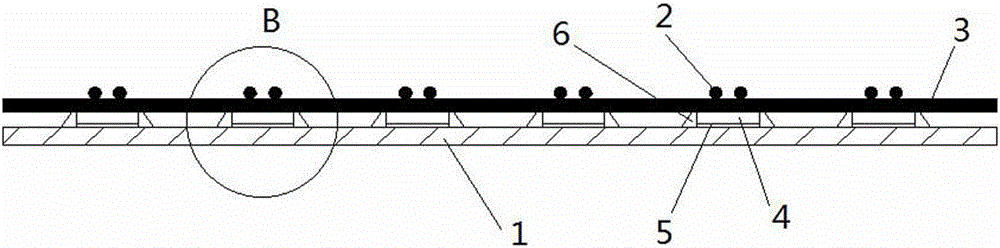

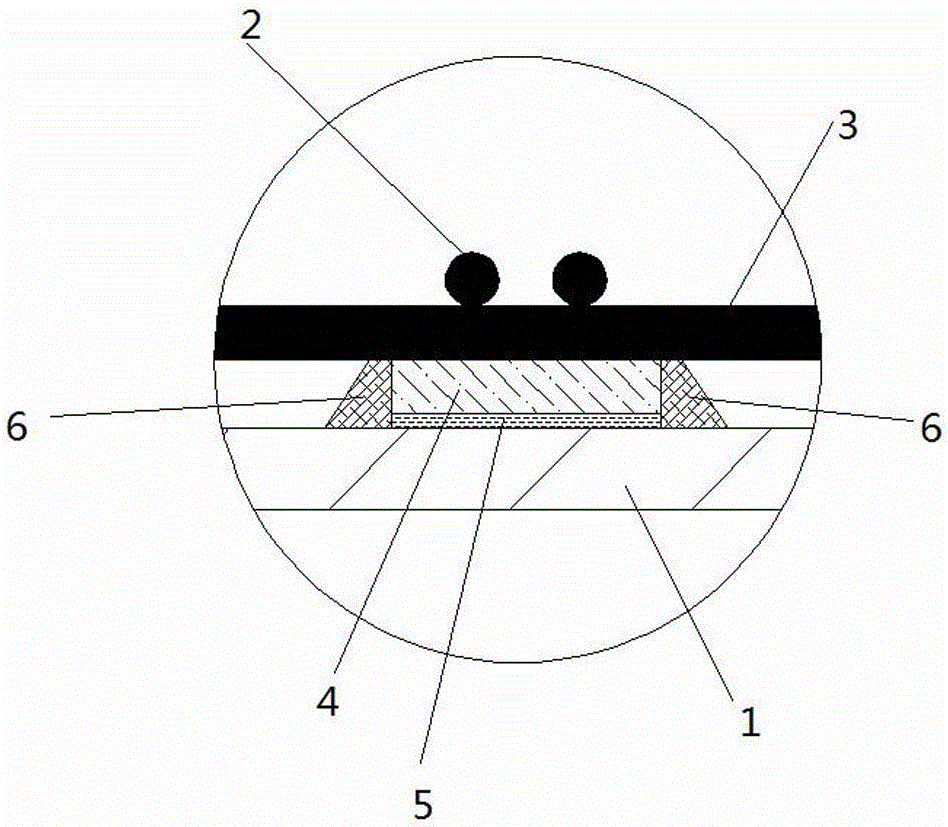

[0063] Such as Figure 1-3 As shown, a glass fiber geogrid for reinforced roadbed, including polyester fiberglass cloth 1 and glass fiber geogrid; glass fiber geogrid is warp-knitted by warp yarn 2 and weft yarn 3 All are glass fiber bundles; an enlarged node 4 is set on the bottom surface of each intersection point of warp yarn 2 and weft yarn 3 . The surface of fiberglass geogrid is coated with a coating. The upper surface of the polyester fiberglass cloth 1 is provided with a number of clamping structures 6, the clamping structures 6 match the shape of the enlarged node 4, and the position of the clamping structure 6 corresponds to the position of the expanded node 4; the expanded node 4 is clamped on the Inside the clamping structure 6. The clamping structure 6 is molded by hot-melt adhesive and bonded to the surface of the polyester fiberglass cloth 1 . The glass fiber geogrid used for the reinforced roadbed is made into a product, and the glass fiber geogrid and the p...

no. 2 example

[0066] Such as Figure 4 As shown, the reinforced glass fiber geogrid for subgrade is slightly different from the clamping structure 6 and the enlarged node 4 in the first embodiment. In the conical base of the clamping structure 6, the size of the top of the base is slightly smaller than the size of the bottom of the enlarged node 4; the enlarged node 4 is made of elastic thermosetting material, which can enter the accommodating space after being squeezed and snapped into in the base.

no. 3 example

[0068] Such as Figure 5 As shown, the reinforced glass fiber geogrid for roadbed is slightly different from the clamping structure 6 and the enlarged node 4 in the first embodiment. The clamping structure 6 is also provided with a stop protrusion 7 to prevent Enlarging node 4 comes out of the base.

[0069] In the first to third embodiments, a hot melt adhesive layer 5 may be provided at the bottom of the enlarged node 4 .

[0070] Enlarging nodes 4 are also arranged on the top surface of the intersection point of each warp yarn 2 and weft yarn 3 .

[0071] The melting point of the hot melt adhesive of the clamping structure 6 and the hot melt adhesive layer 5 of the enlarged node 4 is 140° C. to 160° C.

[0072] The glass fiber geogrid for reinforced roadbed in the above-mentioned embodiment, its manufacturing method comprises the following steps:

[0073] Step 1. Prepare raw materials;

[0074] Step 2, making fiberglass geogrid;

[0075] Step 3, making polyester fiberg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com