Soluble extrusion magnesium alloy and preparation method thereof

A technology of magnesium alloy and extruded state, which is applied in the field of soluble extruded magnesium alloy and its preparation, which can solve the problems of difficult reflow of fragments, long time consumption, and difficulty in drilling and milling, so as to improve construction efficiency and mechanical strength , promote the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a soluble extruded magnesium alloy, which includes the following components in parts by mass:

[0029] Al: 5~10 wt.%;

[0030] Zn: 1~3 wt.%;

[0031] Ni: 0.5~3 wt.%;

[0032] Cu: 0.5~3 wt.%;

[0033] The balance is Mg, and the sum of the parts by mass of the above components is 100%.

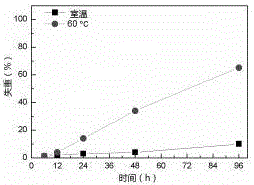

[0034] The above-mentioned soluble extruded magnesium alloy is used to produce fracturing balls and bridge plug isolation tools used in the fracturing reconstruction process of oil and gas fields.

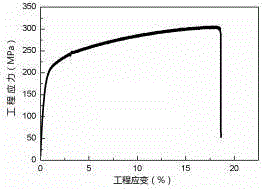

[0035] Mechanical tests show that, compared with cast alloys, the mechanical properties of the soluble extruded magnesium alloy prepared by the invention are greatly improved. This is because the shape of the alloy grains changes during the extrusion process. The original approximately spherical grains are elongated and become finer due to the force. expand. On the other hand, the hot extrusion process reduces the defects such as pores and shrinkage porosity in t...

Embodiment 2

[0037] Magnesium alloy has the characteristics of low density, high specific strength and specific stiffness, and is easy to corrode and dissolve, so it has become the material of choice for processing fracturing and sealing tools. However, the low mechanical properties of cast magnesium alloys limit its use as structural parts. Hot extrusion can homogenize the alloy structure, refine grains, and eliminate casting defects, thereby greatly improving the mechanical properties of magnesium alloys.

[0038] This embodiment provides a method for preparing a soluble extruded magnesium alloy, including two steps of smelting casting and hot extrusion molding:

[0039] (a) Smelting and casting: Weigh Al, Mg, Zn, Cu, and Ni pure metals according to the mass ratio of each component of the soluble extruded magnesium alloy (the purity of Al, Mg, Zn, Cu, and Ni metals ≥ 99.9%), in protective gas (helium, argon or SF 6 +CO 2 A kind of mixed gas) for smelting under ambient conditions. First...

Embodiment 3

[0043] Preparation of magnesium alloy 90Mg-7Al-1Zn-1Ni-1Cu:

[0044] (a) Smelting and casting: Weigh the pure metals of Al, Mg, Zn, Cu, and Ni in parts by mass according to the ratio, and place them in a protective gas of 0.5% SF 6 +99.5%CO 2 After the magnesium ingot is melted at 720°C, other raw materials are added and the temperature is raised to 750°C and stirred for 40 minutes. At 700°C, the alloy liquid is poured into a low-carbon steel mold preheated to 150°C and cooled in the air.

[0045] (b) Hot extrusion molding: machine the cast alloy obtained in step (a) into a cylinder, put it into a heat treatment furnace and heat it to 400°C for heat preservation, and perform hot extrusion treatment after 4 hours. The surface of the alloy before extrusion Apply graphite lubricant. Hot extrusion temperature: 400°C, extrusion ratio: 10.9, extrusion speed: 10 mm / min.

[0046] The room temperature tensile strength of the as-cast 90Mg-7Al-1Zn-1Ni-1Cu alloy obtained through step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength at room temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com