A power-split gasoline-electric hybrid system integrated with a flywheel battery

An oil-electric hybrid power and flywheel battery technology, which is applied to the arrangement of multiple different prime movers of power plants, pneumatic power plants, and general power plants, can solve the problem that the high-efficiency speed ratio range of the composite split system is insufficient to cover the transmission ratio. Interval, low efficiency and other problems, to achieve the effect of high degree of mechatronics, high efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

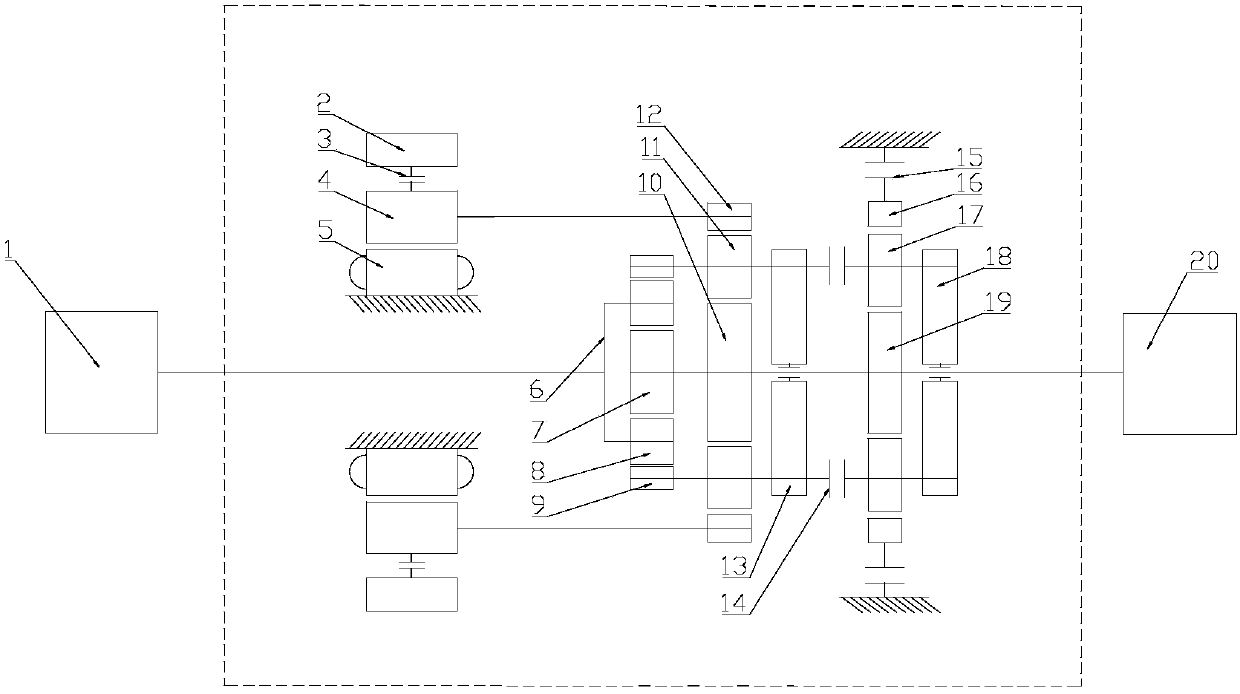

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, a power-split gasoline-electric hybrid system integrated with a flywheel battery includes a planetary coupling device, which includes a three-stage planetary gear transmission mechanism, the primary planetary carrier 6 of the planetary coupling device and the output of the internal combustion engine 1 Shaft connection, four primary planetary gears 8 are symmetrically installed on the primary planet carrier 6, the inner and outer sides of the primary planetary gears 8 cooperate with the primary sun gear 7 and the primary ring gear 9 respectively, and four secondary planetary gears are symmetrically installed on the primary ring gear 9 The planetary gear 11, the inner and outer sides of the secondary planetary gear 11 cooperate with the secondary sun gear 10 and the secondary ring gear 12 respectively, the secondary planetary gear 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com