Disc type tool magazine utilizing harmonic reducer

A harmonic reducer, disc type technology, applied in the field of tool magazines, can solve the problems of reduced tool positioning accuracy, inability to eliminate side clearance, large volume of worm gear and worm, and achieve the effect of low transmission noise, low wear and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

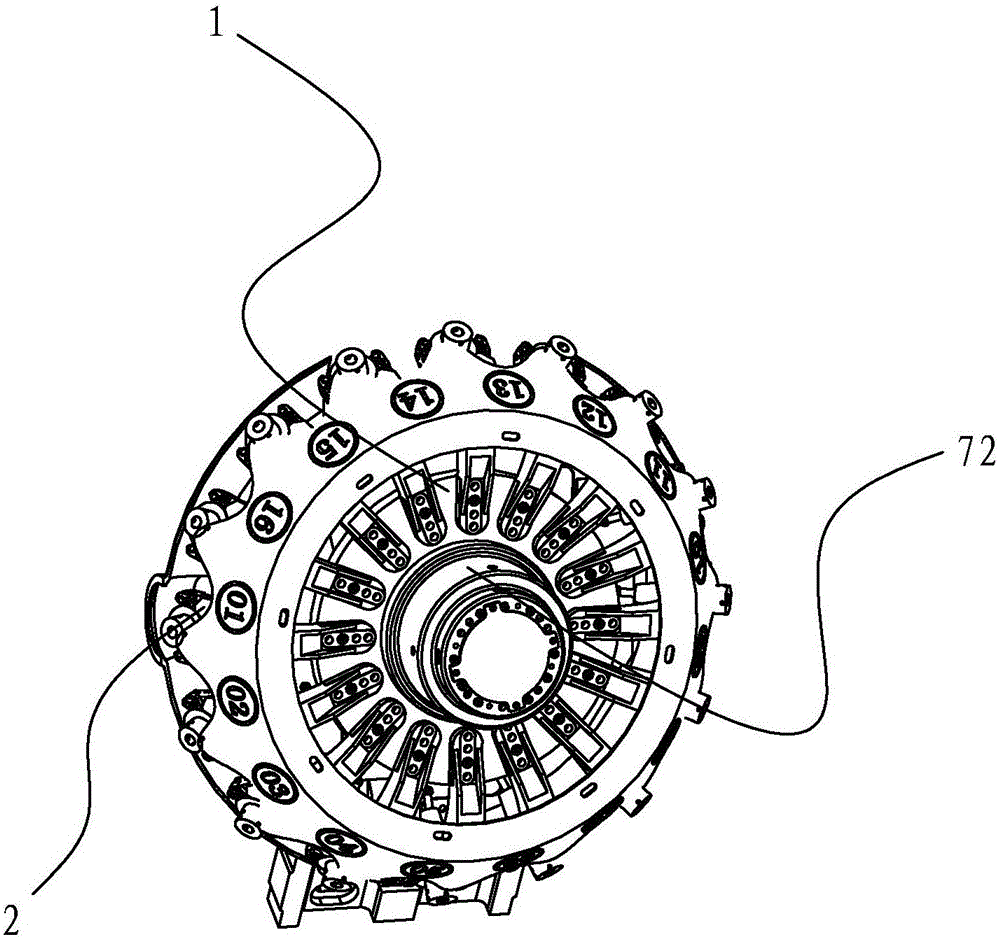

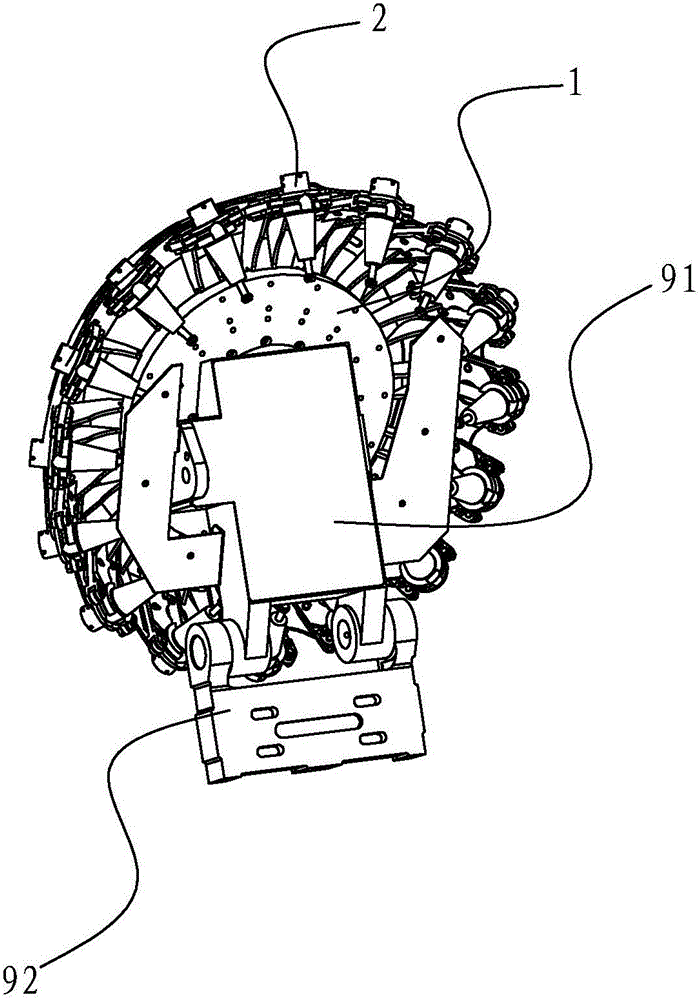

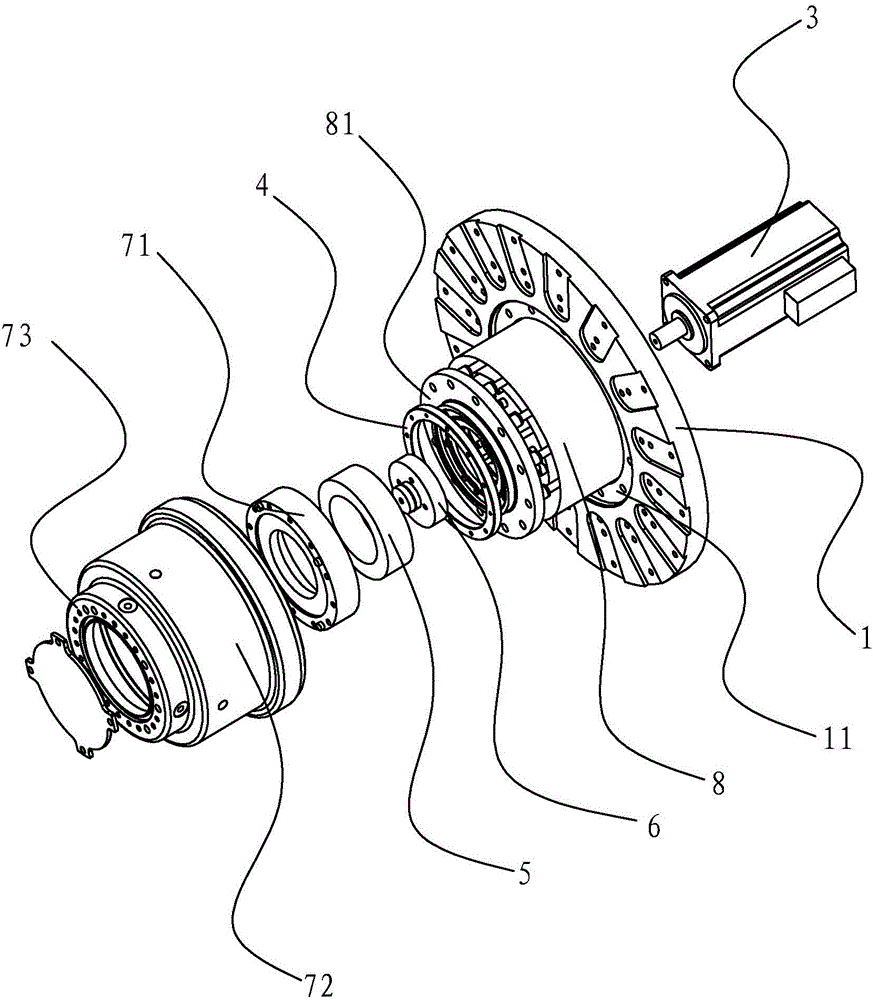

[0019] Such as Figure 1-Figure 4 The first embodiment shown is a disc-type tool magazine using a harmonic reducer, including a rigid spline 4, a flexible spline 5 and a wave generator 6, and the wave generator 6 is connected to a motor 3, a rigid spline 4 or a flexible spline 5 is connected to the driven assembly, and the driven assembly is connected to the cutter head 1, and the clamp 2 is arranged on the cutter head 1. When the rigid wheel 4 is connected to the driven component, the rigid wheel 4 will output to drive the cutterhead 1, and when the flexible wheel 5 is connected to the driven component, the flexible wheel 5 will output to drive the cutterhead 1. The wave generator 6 and the motor 3 can be connected by a pin shaft. It can also be connected by a coupling.

[0020] Such as image 3 and Figure 4 The second embodiment shown is a disc-type tool magazine using a harmonic reducer, including a rigid spline 4, a flexible spline 5 and a wave generator 6, and the wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com