Active shielding type capacitor height-following measuring device

An active shielding and measuring device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem that the cutting head is easily affected by environmental noise, cannot meet the requirements of high-speed and high-precision measurement, and the length and quality of transmission cables Advanced problems, to achieve the effect of improving accuracy, reducing measurement noise, and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

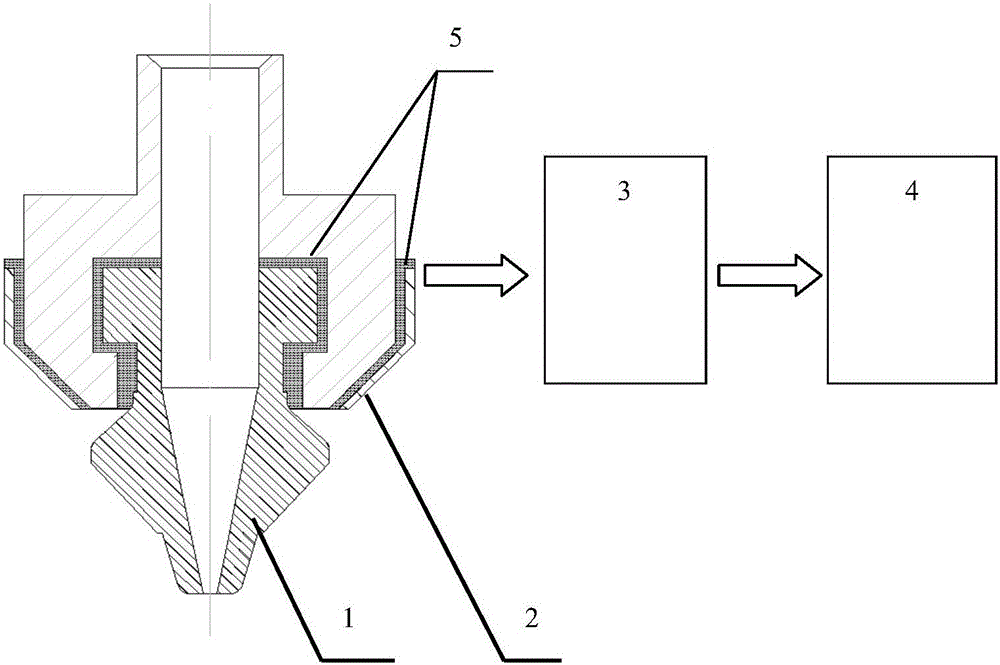

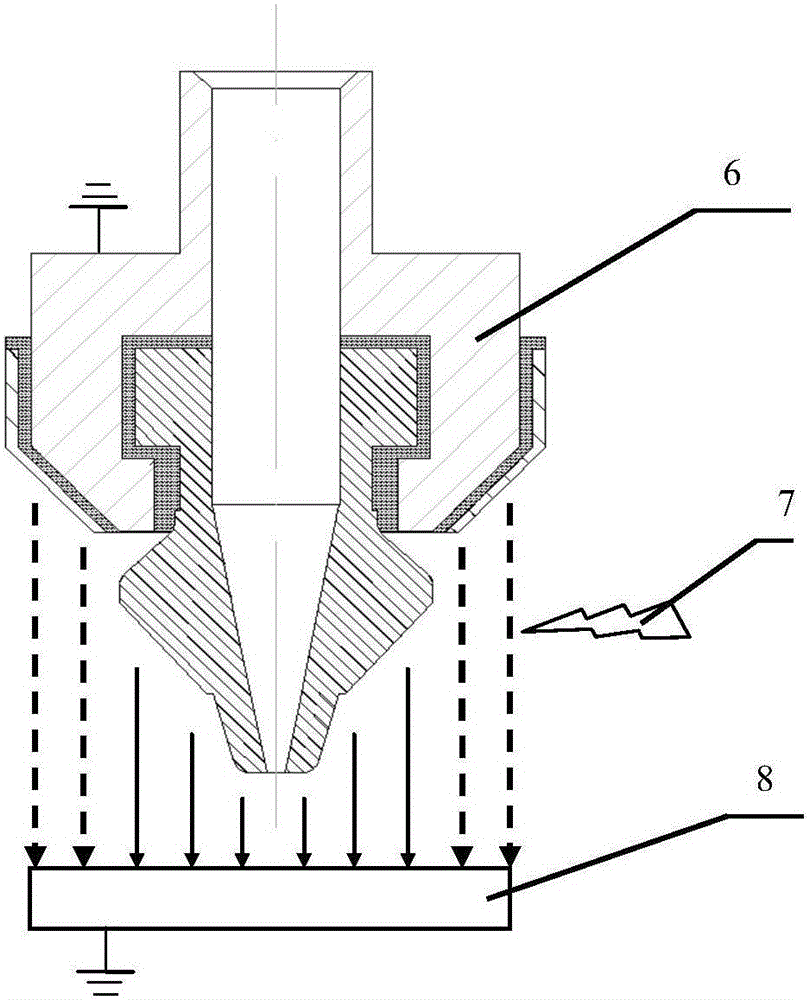

[0028] The invention provides an active-shielded capacitance tracking device. The device isolates the stray capacitance of the cutting head from environmental changes by adding an active shielding layer, and increases the active shielded signal transmission cable to isolate the environment from the stray capacitance of the cable. By eliminating these two main error sources, and designing a corresponding active in the signal processing circuit Shield drive circuit, residual stray capacitance compensation circuit, automatically compensate and match the residual stray capacitance in the cable, greatly improving the measurement accuracy.

[0029] In order to achieve the above purpose, an active shielded capacitive height measuring device is designed, including: capacitive sensor probe 1, active shielding layer 2, active shielded signal transmission cable 3 and high-precision signal processing circuit 4.

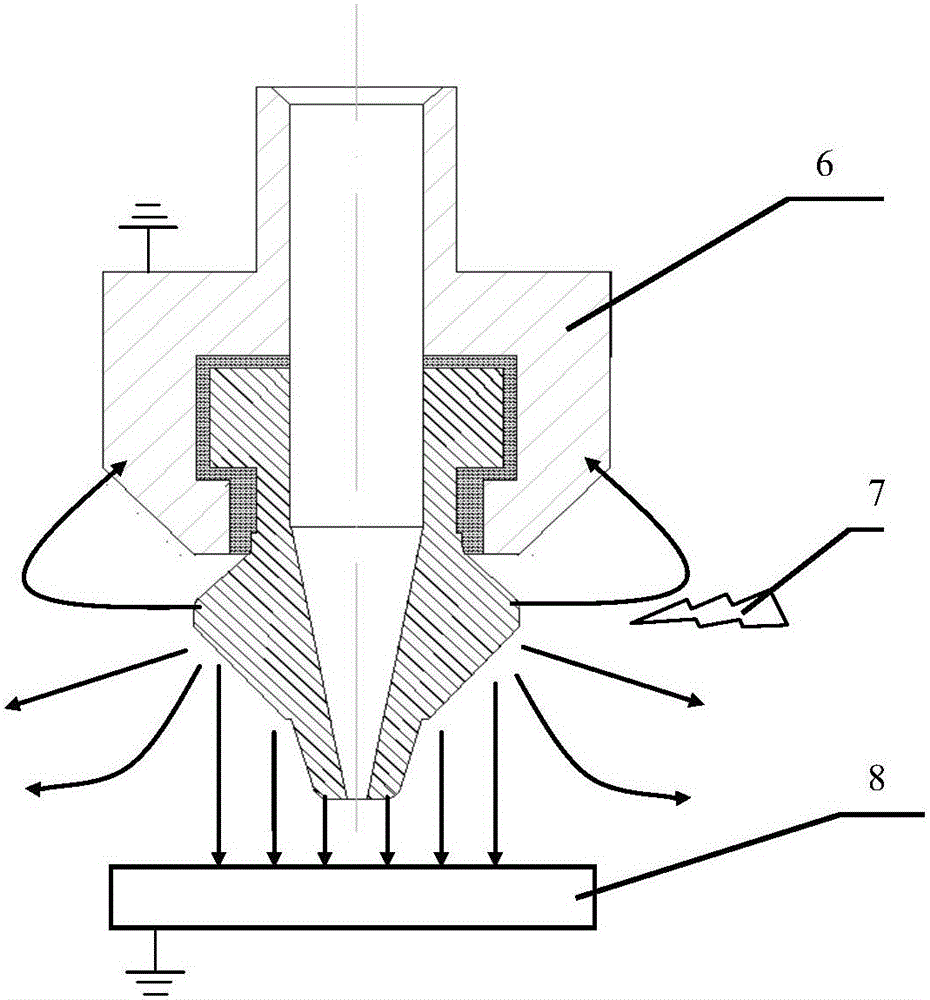

[0030] Conventional capacitance versus height measuring device, see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com