Real-time motor control device for hitting speed of die-casing machine

A real-time control, die-casting machine technology, applied in the field of control devices, can solve the problems of large starting force, accelerated component damage, long reaction time, etc., to achieve the effects of precise repetitive control, precise real-time control, and reduced reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

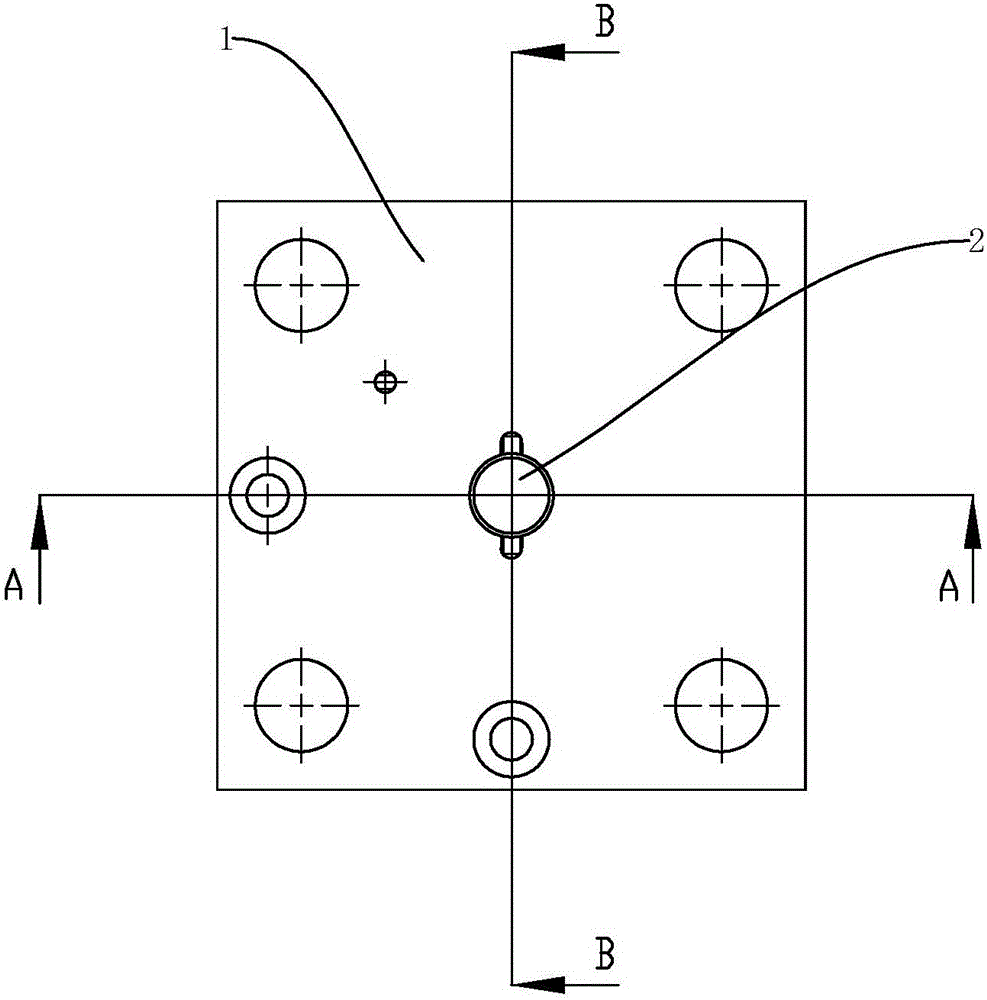

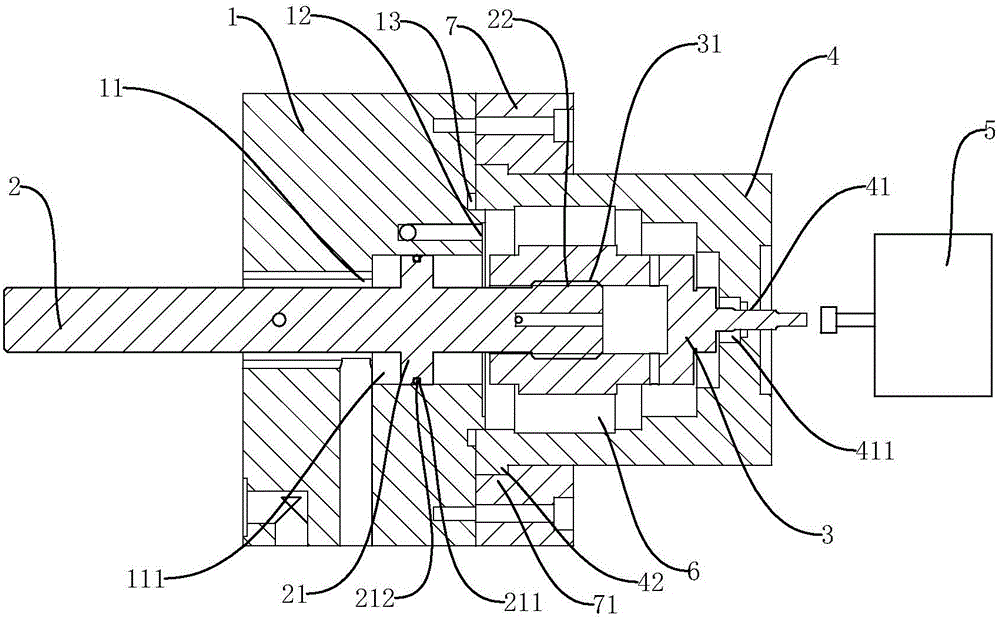

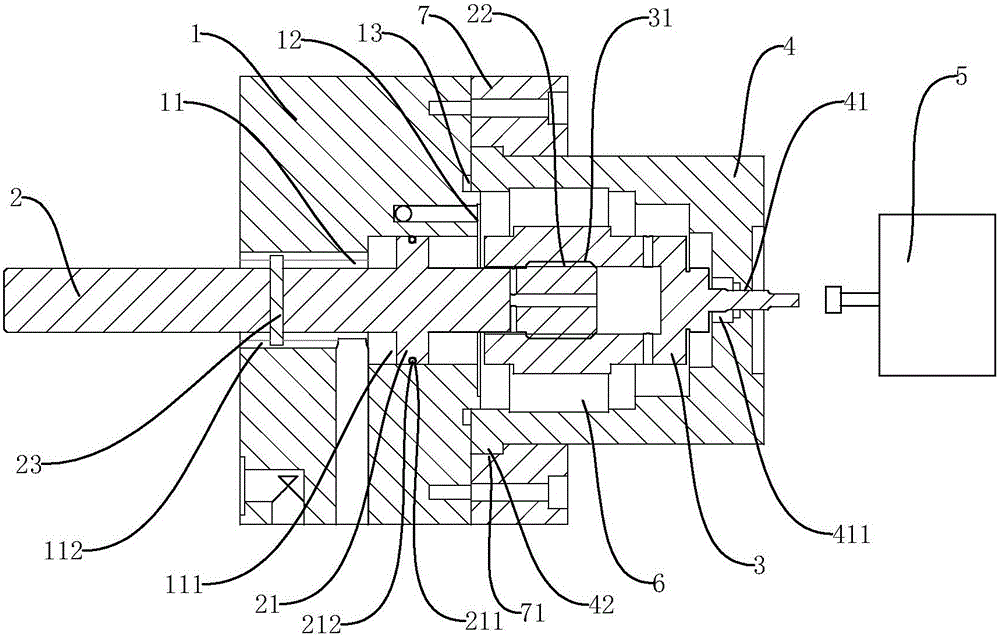

[0022] Such as figure 1 , figure 2 As shown, the control device of the present invention is used to control the feeding speed of the die-casting machine. The output end is connected to the bearing seat 3 of the input end of the ejector rod 2 and the bearing cover 4 for fixing the bearing seat 3. In this design, the control motor 5 is selected to realize automatic control. The bearing cover 4 is provided with a first through hole 41, and the bearing seat 3 The output end passes through the first through hole 41 to connect the bearing of the control motor 5, and the bearing cover 4 is in sealing connection with the cartridge valve cover 1.

[0023] The control device converts the rotational motion of the bearing seat 3 into the linear motion of the ejector rod 2 through the cooperative connection between the bearing seat 3 and the ejector rod 2, and the linearly moving ejector rod adjusts the feeding speed of the die-casting machine. The specific structure is as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com