Acid gas separation and sulfur recovery integrated device and method for synthesis gas

A synthesis gas and sulfur recovery technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as complex processes, and achieve the effects of simple process flow, simplified operation, and fewer control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in combination with specific implementation examples.

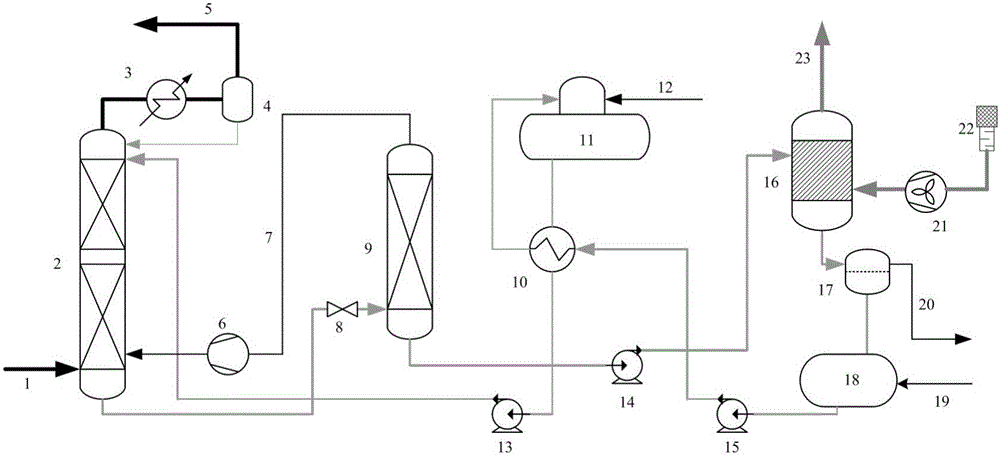

[0038] Such as figure 1 As shown, this embodiment is illustrated by applying the device and method of the present invention to desulfurization and sulfur recovery of syngas in an IGCC power plant. In the IGCC power plant, the coal first completes the gasification process in the gasifier, and generates 2 The crude synthesis gas of S pollutants must be purified and desulfurized before the synthesis gas is sent to the gas turbine for power generation.

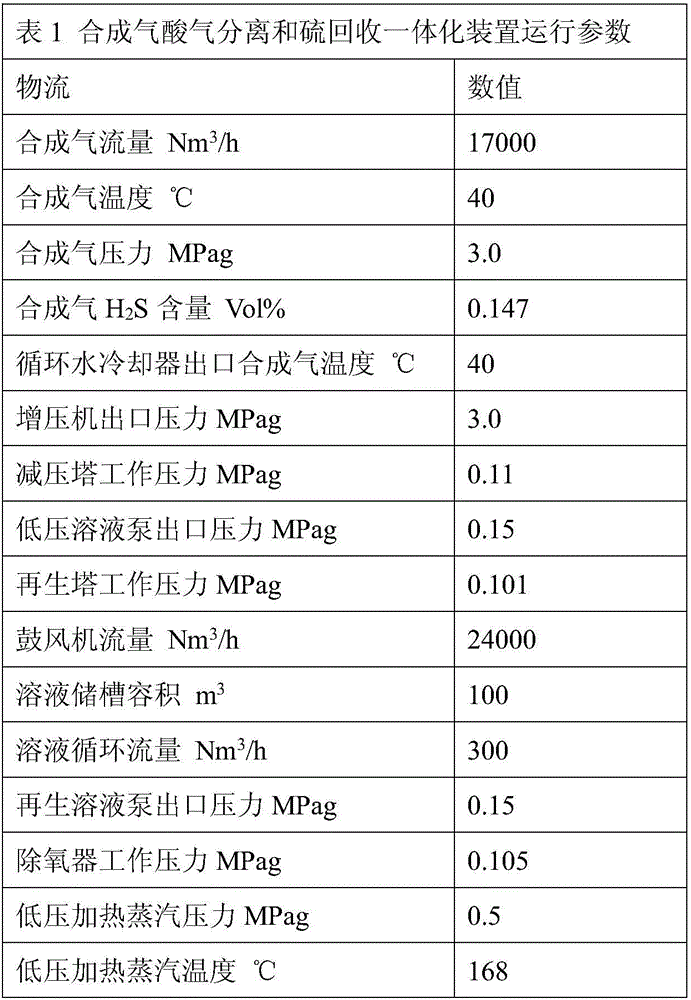

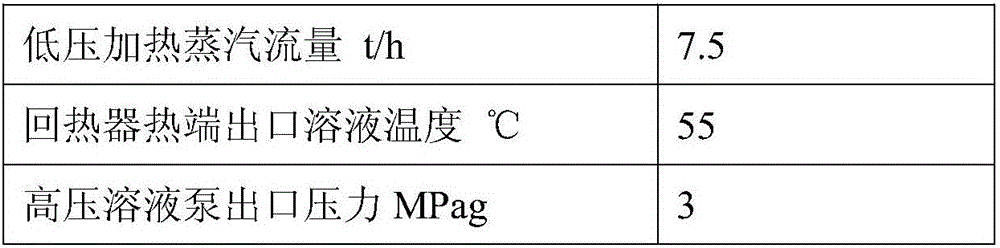

[0039] After the synthesis gas from the gasifier is firstly deashed and washed with water, only H is left in the synthesis gas. 2 S pollutant composition, synthesis gas pressure 3.0MPag, temperature 40°C, of which H 2 The content of S component, determined according to the type of coal used, is about 0.147% of the total volume. As shown in the figure, the sulfur-containing synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com