One-piece candy moulding machine

A molding machine, an integrated technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of inconvenient setting of the return mechanism, different shapes of sugar cubes, low work efficiency, etc., to achieve simple structure and work efficiency. High, the effect of correcting deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention combined with the accompanying drawings to further illustrate the present invention.

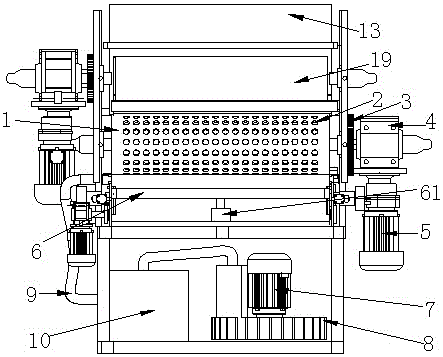

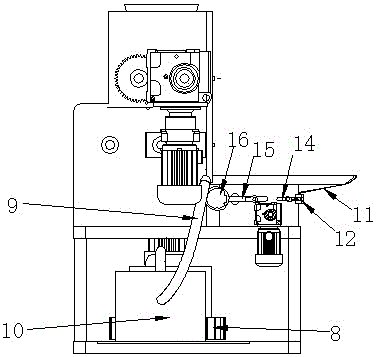

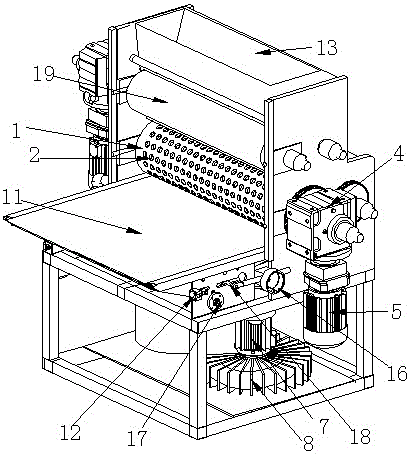

[0030] As can be seen from the figure, the integrated sugar block forming machine of the present invention includes a pressing device, a suction device and a feeding device. A pair of pressing rollers 19 are provided on the upper side of the pressing device, and a hopper 13 is provided on the upper side of the pressing rollers 19. The dough-like material in the hopper 13 enters between the two pressing rollers 19 in a pair, and is pressed into a sheet-like sugar material, which is pressed by a pressing device to form a sugar mass. The suction device is used to suck out the sugar cubes and drop the sugar cubes onto the conveyor belt 11 in the feeding device. The shaped sugar cubes are conveyed by the feeding device to the packaging station or the next chocolate coating station.

[0031] The pressing device includes two rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com