Fixed contact structure of bar-type off-circuit tap-changer

A technology of tap changer and static contact, which is applied in electrical switches, electrical components, circuits, etc., can solve the problems of increasing the manufacturing cost of transformers, large internal space of transformers, and unsightly arrangement of leads, and achieves improved reliability and structure. Compact, volume-reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

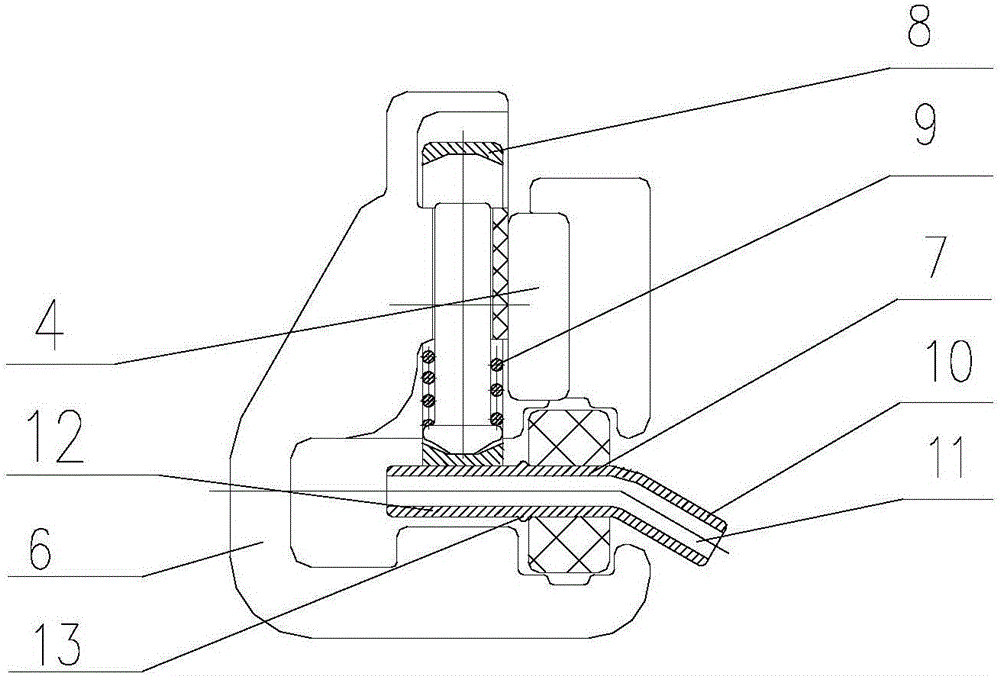

[0023] Such as Figure 1-2 As shown, this embodiment provides a bar-shaped off-excitation tap changer, including an insulating rod 5 and a bracket 2, an operating positioning device 1 is installed on the supporting bracket 2, and a driving gear 3 is arranged at the lower end of the operating positioning device. Above the insulating rod 5, a rack mobile frame is arranged, and the rack 4 of the rack mobile frame meshes with the gear of the operation positioning device 1, so that the rack mobile frame can move back and forth along the length direction of the insulating rod; Static contacts 7 are installed at intervals in the length direction, and each phase static contact 7 is equipped with a moving contact assembly, which is connected to the rack moving frame 10, and the moving contact assembly includes a moving contact bracket 6 And the moving contact 8 installed in the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com