A metal 3D printing preparation method with bionic surface structure

A surface structure, 3D printing technology, used in additive manufacturing, process efficiency improvement, additive processing, etc., can solve problems such as wear resistance, friction reduction, resistance increase, poor regularity and repeatability, etc., to improve service life, Easy to operate, good wear resistance and resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

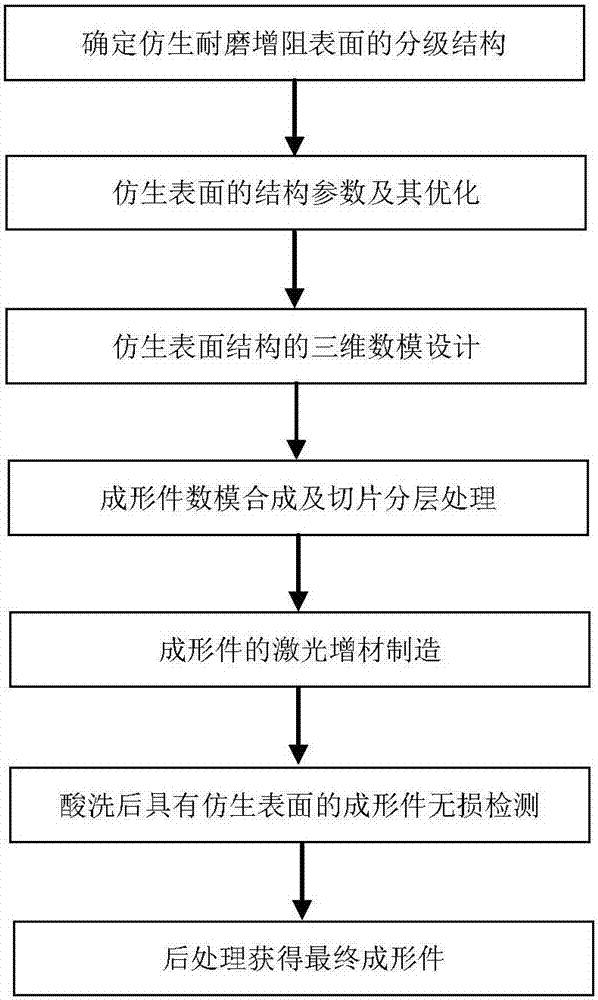

[0019] Attached below figure 1 The method for preparing metal 3D printing with bionic surface structure of the present invention will be specifically described.

[0020] A metal 3D printing preparation method with a bionic surface structure. The preparation method includes the following steps:

[0021] 1) Determine the bionic surface structure according to the requirements of the wear resistance and resistance increase performance of metal parts, where the bionic surface structure is a hierarchical structure that can be prepared by laser additive manufacturing forming technology, including: the first-level macrostructure, which The surface changes have been determined during the design of mechanical parts; the second-level microstructure can actually be completed by the laser additive manufacturing in the following steps of the present invention; the third-level microstructure has a minimum size of 10-90μm structure;

[0022] 2) Using simulation technology to compare the friction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com