A process for preparing tofu with a household soybean milk machine

A soymilk machine and soymilk technology, which is applied in applications, dairy products, cheese substitutes, etc., can solve the problems of roughness and poor quality of tofu products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

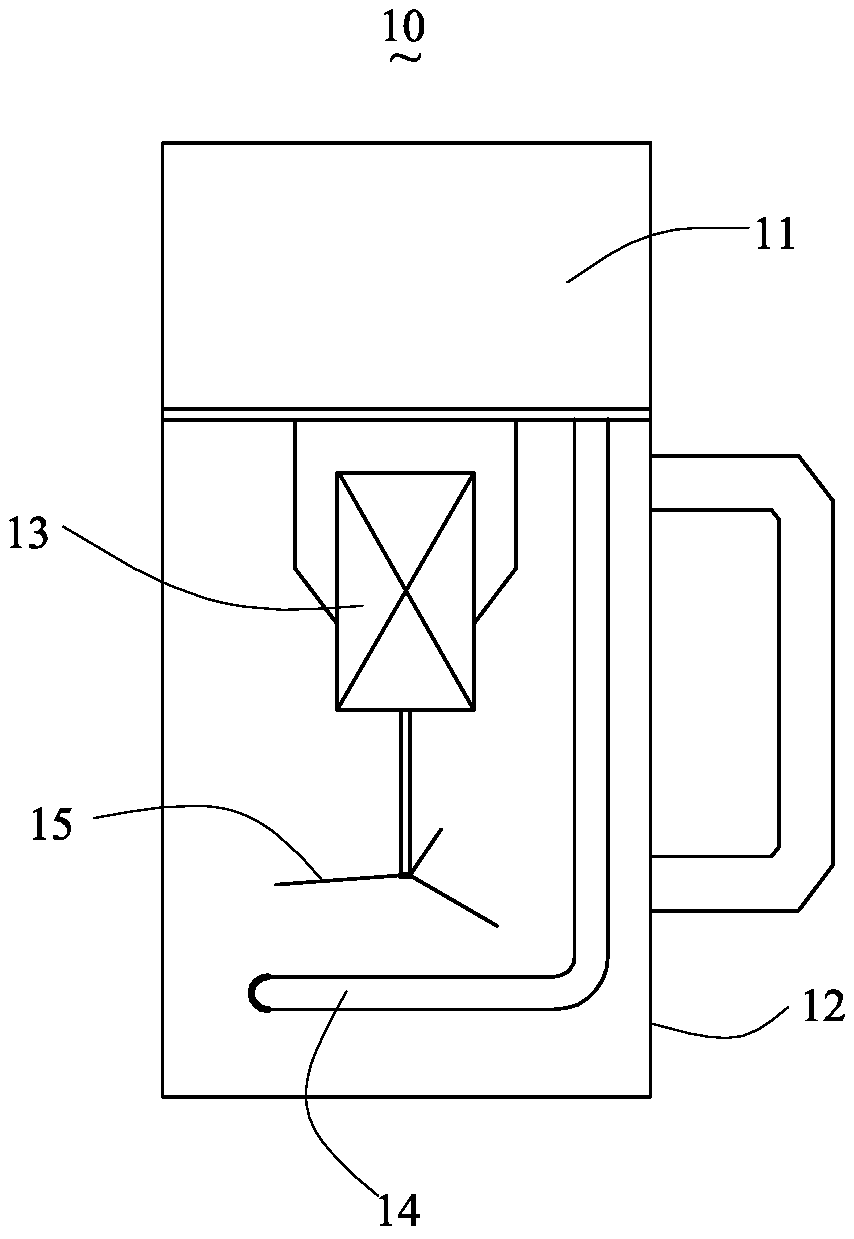

[0034] see figure 1The schematic diagram of the household soybean milk machine used in the first preferred embodiment of the method for preparing high-concentration soybean milk, the household soybean milk machine 10 includes a machine head 11, a cup body 12, a motor 13, a heating element 14 and a crushing tool 15, the The machine head 11 is buckled on the cup body 12, the motor 13 is installed in the machine head 11, the motor 13 drives the crushing tool 15 to rotate, the heating element 14 is used to heat the cup body 12, and the crushing tool 15 is located in the cup body 12 .

[0035] The process for preparing tofu by the household soymilk machine at least includes the following stages:

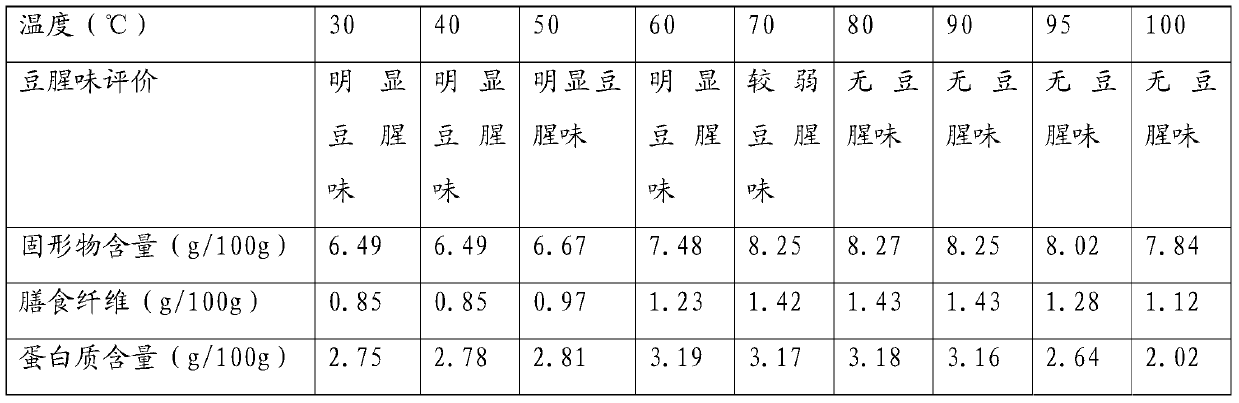

[0036] a. Full wall breaking stage: the first step: the pulping material is kept in the first temperature range for 1 to 10 minutes, and the first temperature is 70°C to 90°C; then proceed to the second step: the crushing tool is first The rotation speed is 16000 to 35000 rpm, and it is...

Embodiment approach 2

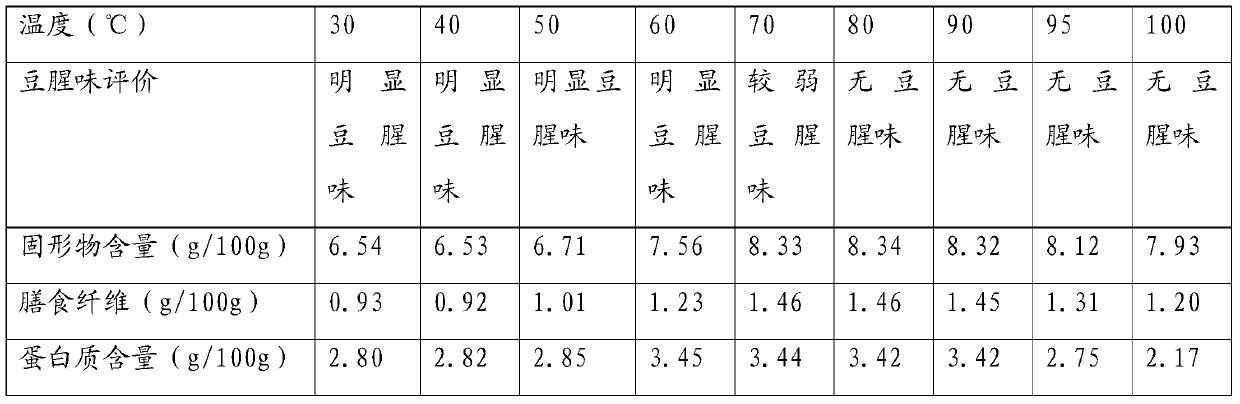

[0093] The difference between the second preferred embodiment and the first preferred embodiment of the process of preparing tofu with a household soymilk machine is that: the second step of the full wall-breaking stage also includes a heating element to continue heating the pulping material To 90°C to 100°C and keep in the range of 90°C to 100°C for pulverization.

[0094] It should be noted here that during the crushing process, heating can be continued or intermittently to keep the pulping material within the second temperature range, as long as the temperature is within the range of 90°C to 100°C without heating.

[0095] In this embodiment, the time for raising the temperature to the second temperature is 1 to 10 minutes.

[0096] Take the soybean water ratio of 1:11, the first temperature of 80°C, the holding time of 10 minutes, the rotational speed of the crushing tool at 22000 rpm, and the crushing time of 6 minutes as an example. The relationship between solids, part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com