Method of load shedding of floating wind turbine generator system based on semi-active structure control of magneto rheological damper

A magnetorheological damper, structure control technology, applied in the direction of machine/engine, control algorithm type, wind turbine control, etc. effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

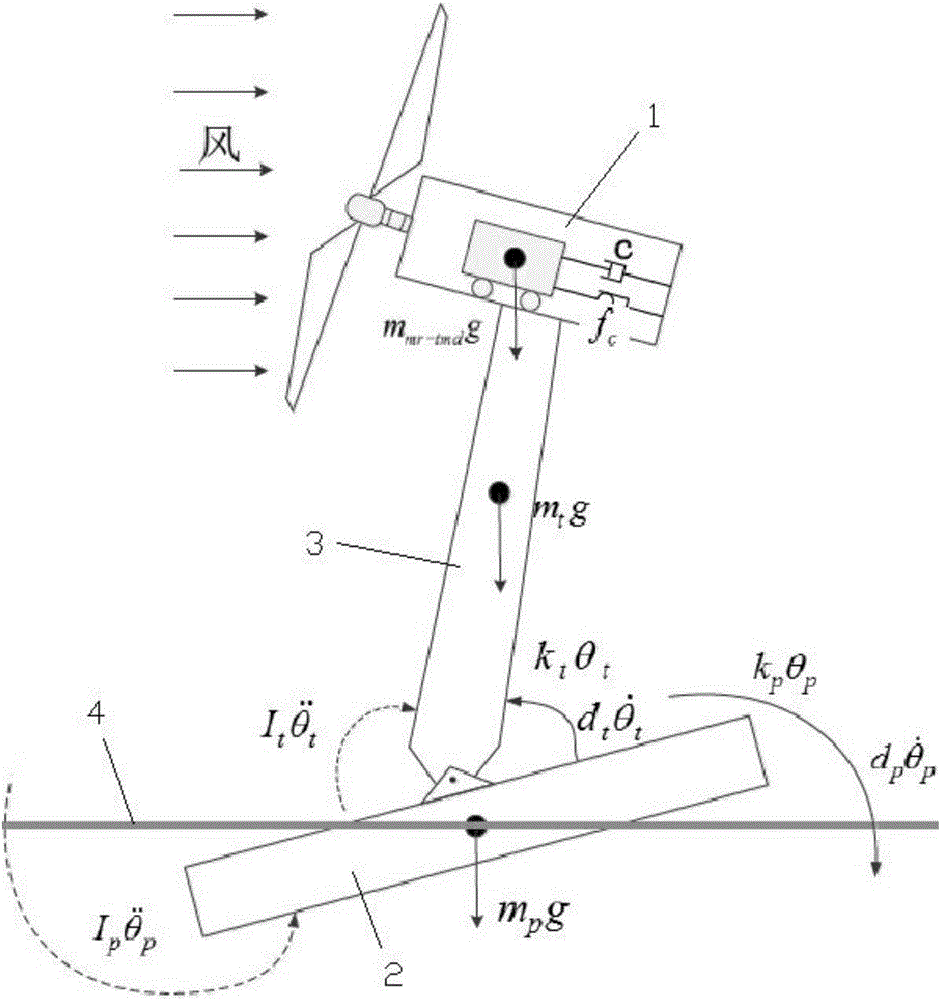

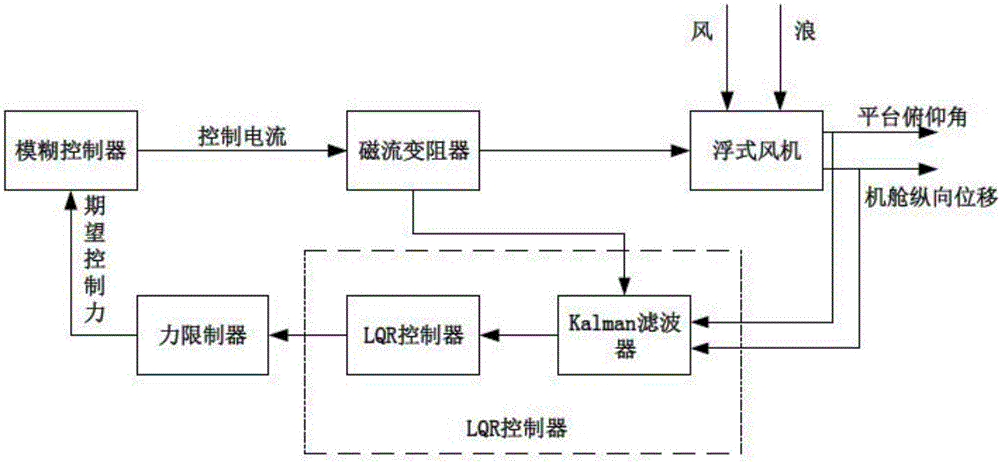

[0023] As shown in the figure, this embodiment is based on the semi-active structural control method of the magneto-rheological damper for floating wind turbine load reduction, including the following steps:

[0024] 1) Analyze the structure of the magnetorheological damper, and obtain the force-displacement relation of the magnetorheological damper:

[0025] F = c 0 x · + f c sgn [ x · ] + f 0 ,

[0026] In the formula, F is the magnetorheological damping force, C 0 is the damping coefficient, is the displacement of the piston relative to the cylinder, f c is the Coulomb force, f 0 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com