Direct Contour Control Method of Plane Cartesian Coordinate Motion System

A plane Cartesian coordinates and motion system technology, applied in the direction of digital control, program control system, electrical program control, etc., can solve the problems of low precision and difficult adjustment, achieve high-precision contour control, simplify the adjustment process, and realize contour control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation steps of the method of the present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that the following examples are illustrative, not limiting, and the content covered by the present invention is not limited to the following examples.

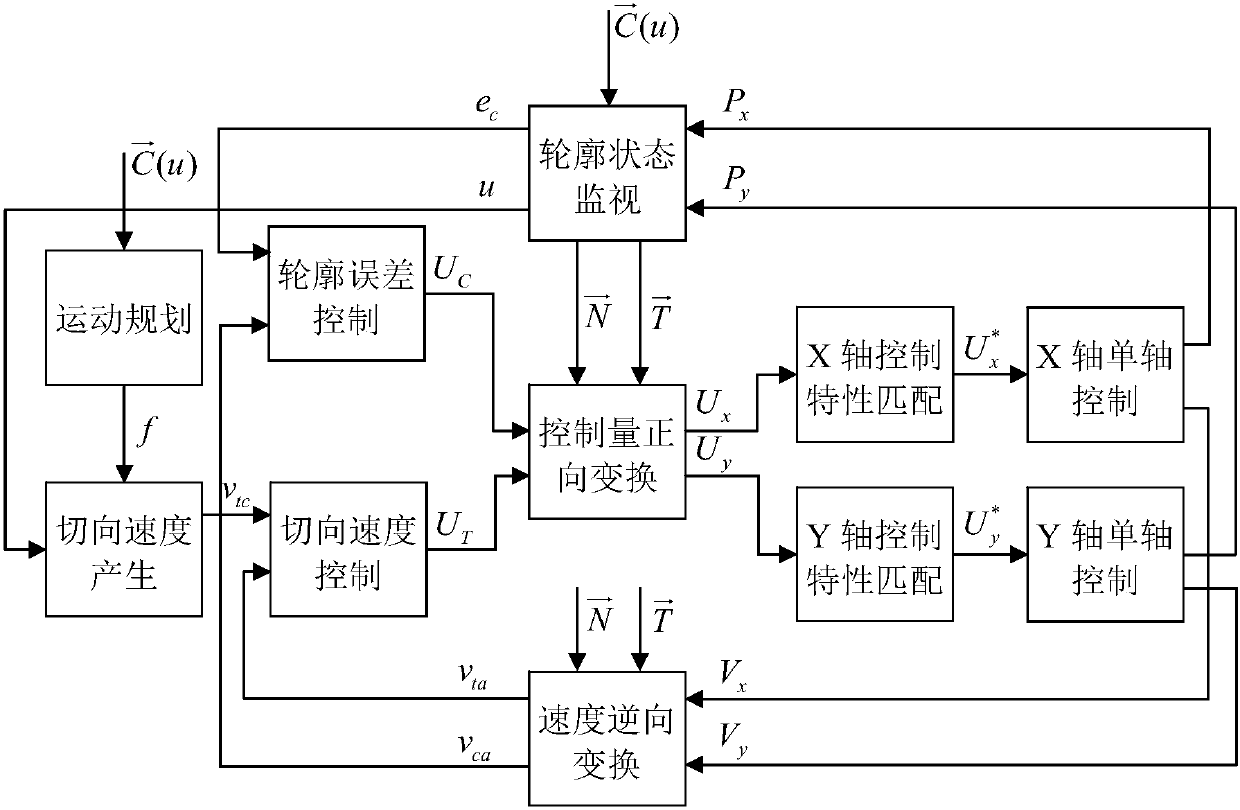

[0035] The direct contour control method of the planar Cartesian coordinate motion system is completed through the following 11 modular logical processing calculations. The specific steps are as follows:

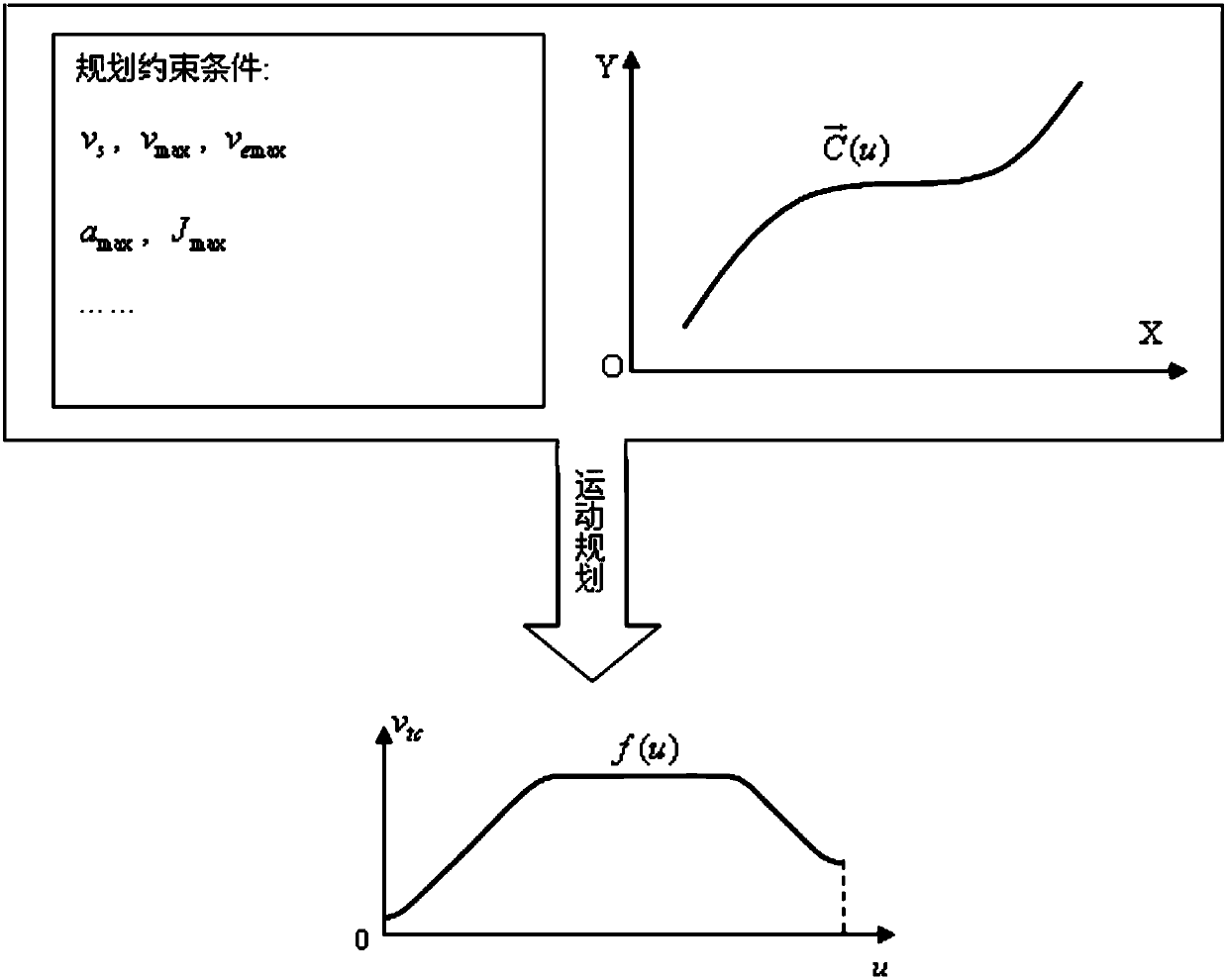

[0036] (1) Motion planning: generate contour motion tangential speed command planning; according to the programming contour input by the user Plan the contour motion process with the motion planning constraints, and generate the contour motion tangential velocity command v tc The relationship function f, v with the profile curve parameter u tc =f(u), for the subsequent real-time control link.

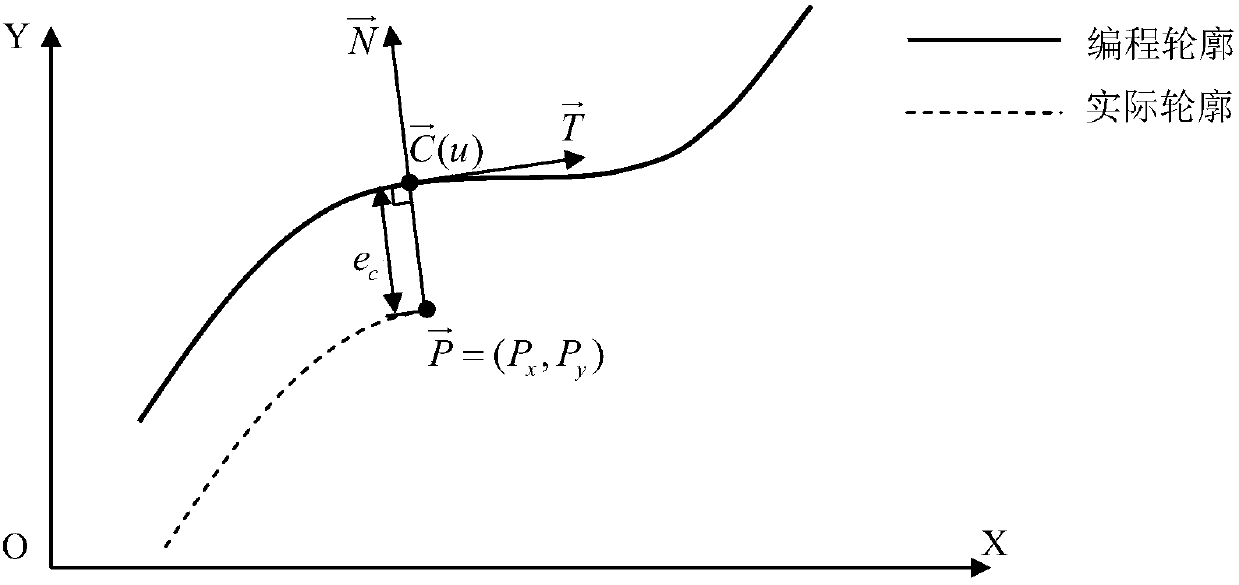

[0037] (2) Contour status monitoring: according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com