Gas collection device and gas collection method for volatilized gas during epoxy resin curing

A technology for epoxy resin curing and volatile gas, which is applied in the direction of measuring devices, sampling devices, instruments, etc., can solve the problems of low volatility, low curing agent, and no clear device and method for volatile gas, so as to ensure accuracy and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

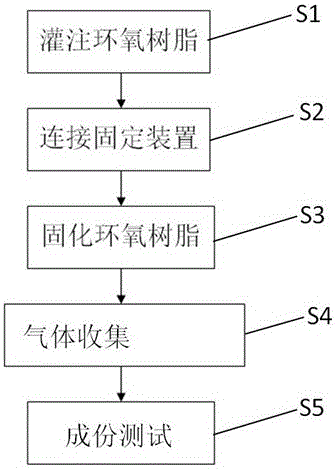

[0049] (i) Pouring epoxy resin

[0050] At room temperature, put JEL-55 epoxy resin and modified amine curing agent into a beaker, where the mass percentage of epoxy resin and curing agent is 3:1, and use a glass rod to stir the epoxy resin and curing agent evenly , place the glass rod obliquely in the filling pipe 2, and pour the above mixture into the gas collecting bottle 1 along the glass rod.

[0051] (ii) Connecting Fixtures

[0052] Put the sealing ring on the annular contact surfaces of the upper connecting plate 9 and the lower connecting plate 10, and fix the upper connecting plate 9 and the lower connecting plate 10 by the screw rod 7.

[0053] (iii) Curing epoxy resin

[0054] Turn the control valve 6 to move the piston 8 downwards to ensure that the piston 8 is under the outlet pipe 4. After the adjustment is completed, place the device in a drying oven, solidify at a temperature of 60°C for 6 hours, and cool in the furnace.

[0055] (iv) Gas collection

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com