Sensor structure used for Doppler flow instrument and assembly method thereof

A technology of Doppler flow and sensor, which is applied in the field of flow measurement of industrial fluids, can solve the problems affecting the measurement accuracy of Doppler flow sensor, misoperation of flow monitoring system, on-site production loss, etc., and achieve stable and reliable structure, good resistance Effect of electromagnetic radiation function and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

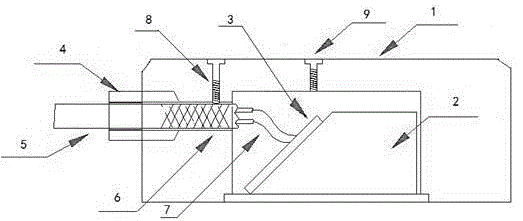

[0034] Refer to attached image 3 , a sensor structure for a Doppler flow meter, consisting of two transducers with the same structure, the transducer includes a main body shell 1, an acoustic wedge 2, a Doppler resonant chip 3, a lock 4, Signal cable 5, shielding net 6, twisted pair 7, shielding fastening screw 8 and glue injection screw opening 9, the main body shell 1 is a metal cavity structure with a sound wedge 2 inside, and the main body shell 1 is provided with a locking hole, fastening screw hole and glue injection screw opening 9, the Doppler resonator chip 3 is arranged on the acoustic wedge 2; the shielding net 6 is arranged on the signal cable 5, penetrates into the main body shell 1 through the locking hole, and the signal The upper twisted pair 7 at the end of the cable 5 is connected to the Doppler resonant chip 3; the shielding fastening screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com