Box structure for tunnel sterilizing dryer and laminar flow control method of box

A box structure and dryer technology, which is used in drying solid materials, drying gas layout, dryers, etc., can solve the problems of inconvenient inspection and maintenance of internal structures, low space utilization of air flow passages, and unfavorable control of air flow uniformity. and other problems, to achieve the effect of convenient plant layout, obvious lamination effect, and better uniformity of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

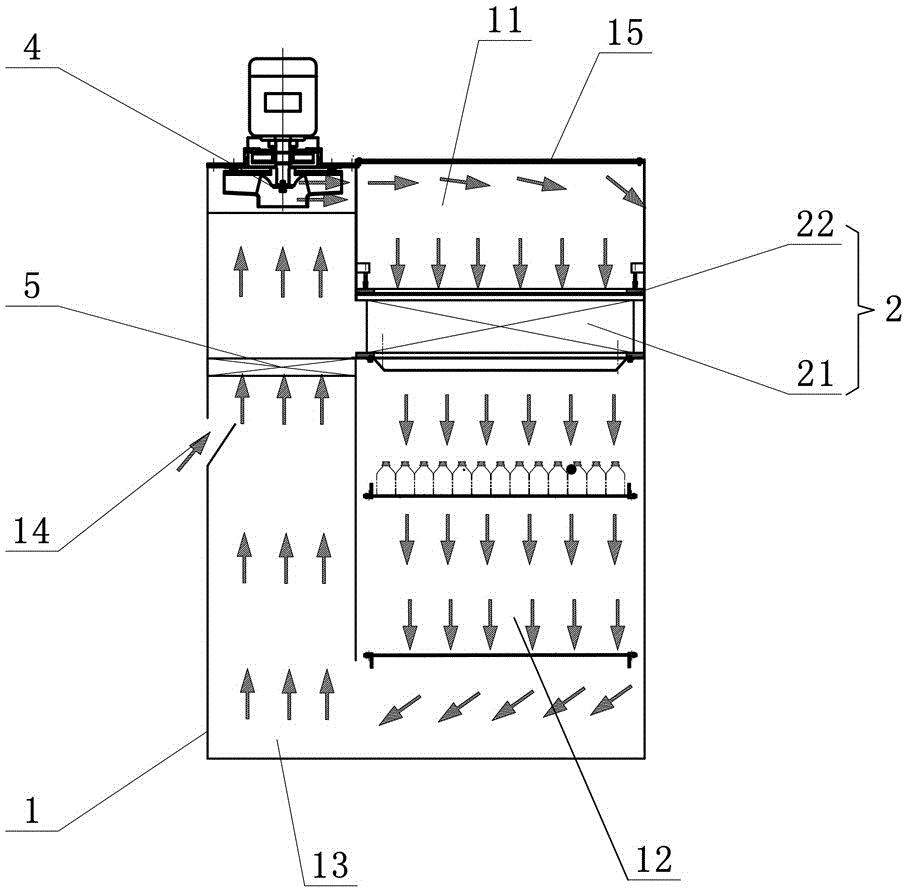

[0027] Such as figure 1 As shown in the first embodiment of the box structure for the tunnel type sterilization dryer of the present invention, the inside of the box 1 is provided with a first cavity 11, a second cavity 12 and a return air cavity in sequence from top to bottom. 13. The bottom of the first cavity 11 communicates with the top of the second cavity 12, the two ends of the return air cavity 13 communicate with the first cavity 11 and the second cavity 12 respectively, and the bottom of the first cavity 11 is equipped with a filter The box body 1 is equipped with a fan assembly 4 for introducing air into the first cavity 11 near the top of the air return cavity 13 . As shown by the arrow in the figure, the fan assembly 4 inhales the gas and then pressurizes it and discharges it into the first cavity 11 to achieve the purpose of continuous blowing. The air flow flows downward from the first cavity 11 to the filter assembly 2 for filtering, and then Enter the second ...

Embodiment 2

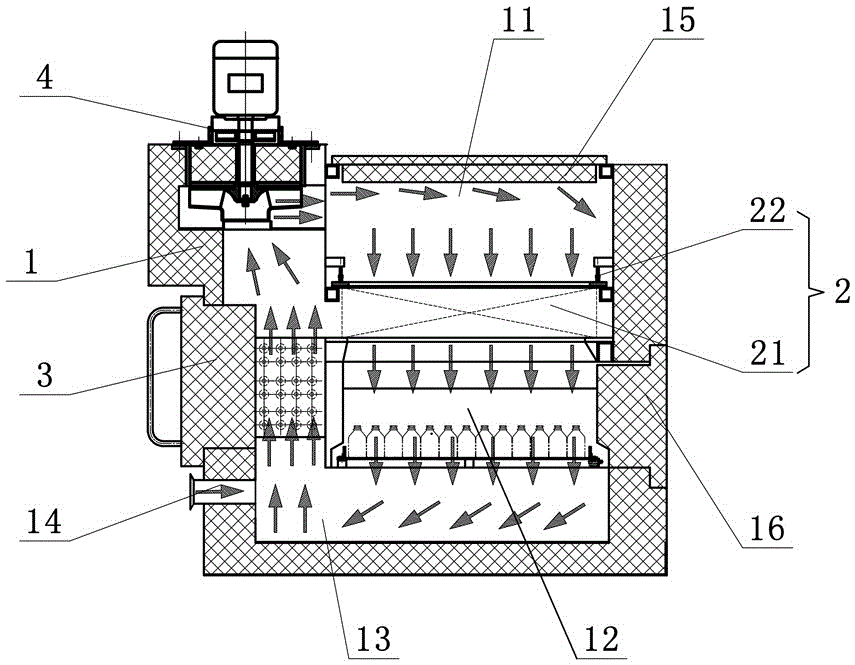

[0034] Such as figure 2 As shown, the second embodiment of the box structure for the tunnel type sterilization dryer of the present invention, the box 1 is basically the same as that of the embodiment 1, the only difference is that: the side of the box 1 is installed to extend to the return air cavity 13 inside the heating element 3. The heating assembly 3 is mainly used to heat the air flowing in from the preheating section and the air flowing in from the supplementary air outlet. The box structure is suitable for the heating section of the tunnel type sterilization dryer. The air flow of the heating section structure also adopts the internal circulation mode. Under the adsorption load of the high-temperature laminar flow fan assembly 4, it is blown into the first cavity 11 composed of the filter assembly 2 and the top door 15. Since the air flow space is relatively large, it is blown vertically to the filter 21 by utilizing the lamination effect of the air flow. After the ...

Embodiment 3

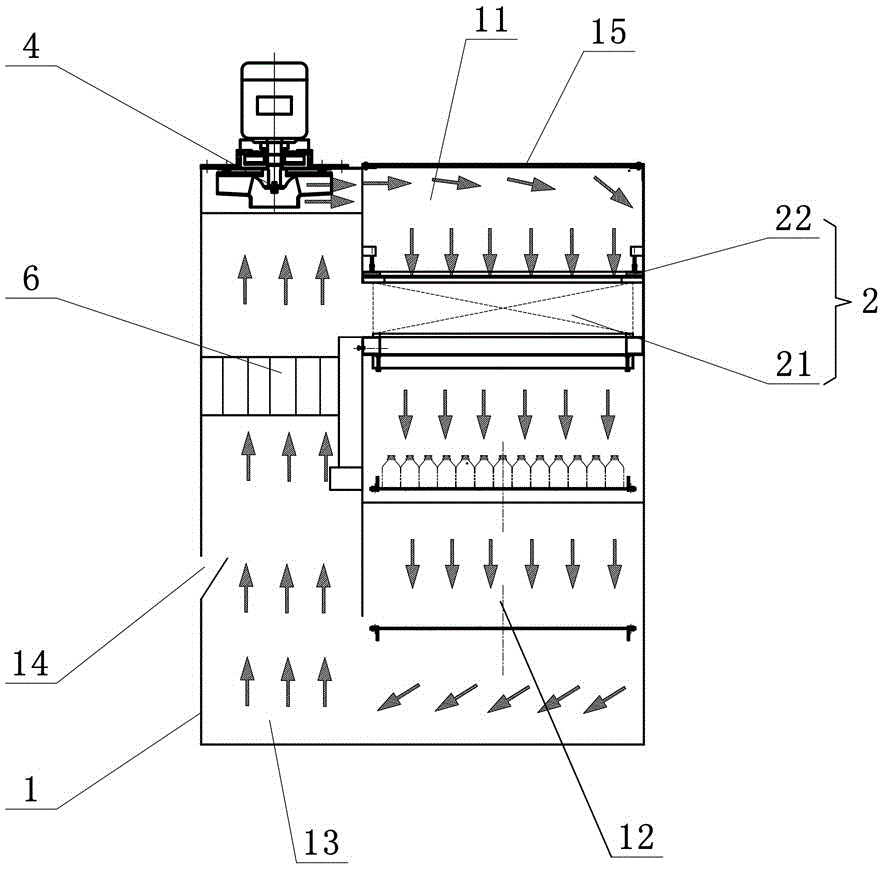

[0037] Such as image 3 As shown, the third embodiment of the cabinet structure for the tunnel type sterilization dryer of the present invention, the cabinet 1 is basically the same as that of Embodiment 1, the only difference is that a surface cooler assembly 6 is installed in the return air cavity 13 . The surface cooler assembly 6 is mainly used to cool the air flowing in from the supplementary air inlet. The box structure is suitable for the cooling section of the tunnel type sterilization dryer. The air flow of the cooling section structure also adopts the internal circulation mode. 4 is blown into the first cavity 11 formed by the filter assembly 2 and the top door 15 under the action of the adsorption load of 4. Since the air flow space is relatively large, the lamination effect of the air flow is used to vertically blow to the filter 21, and the air flow blows to the filter 21 after being filtered. The bottle body in the second chamber 12 is cooled and cooled, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com