Smashing and drying device for straw feed for animals

A technology of straw feed and drying device, which is applied in the drying of granular materials, the dryer and drying of static materials, etc., can solve the problems of low processing precision, waste, and difficult to digest, and achieve the effect of high pulverization degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

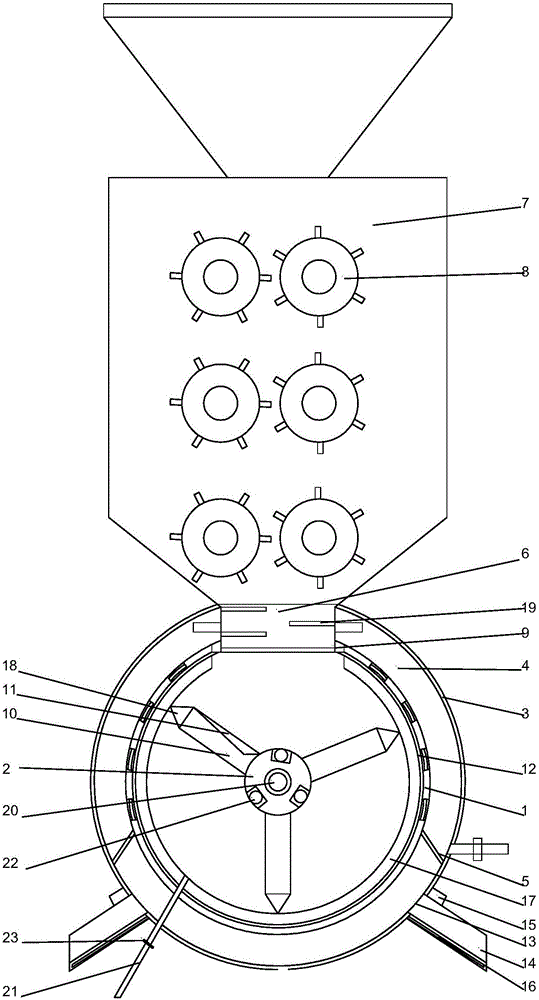

[0023] Such as figure 1 As shown, a crushing and drying device for animal straw feed includes a box body 1 and a rotating shaft 2 arranged in the middle of the box body, and a discharge cylinder 3 is set outside the box body, and the discharge cylinder and the A discharge cavity 4 is formed between the casings, the middle part of the discharge cavity is provided with a partition 5, and the inner wall of the discharge cylinder above the partition is a corrugated structure. A feed hole is arranged on the partition, and the partition divides the discharge cavity into upper and lower parts, and a heater is arranged in the partition, and on the side wall of the discharge cavity A water outlet valve is provided, and the water outlet valve is located above the partition plate, and crushed material output ports 13 are respectively arranged on both sides of the bottom of the discharge cavity. The feed inlet 6 connected to the inner side of the casing is provided with a crushing casing...

Embodiment 2

[0026] In this embodiment, on the basis of Embodiment 1, in order to reduce the moisture content in the material conveniently, in this embodiment, preferably, a cavity is provided in the middle of the rotating shaft, and a heating device is provided in the cavity. Silk.

[0027] In order to make the feed more dry, so that it is more convenient for the cutter to cut it, in this embodiment, preferably, a ventilation pipe 21 communicating with the box body is provided at the lower end of the discharge cylinder, and in the A one-way valve 23 is arranged on the ventilation pipe. The hot air is input into the box through the ventilation pipe to accelerate the air flow in the box, and at the same time increase the temperature in the box to evaporate and discharge the water more quickly. When the material is drier, it is easier to cut when it is cut by the cutter.

[0028] Since the plant stalks may contain some harmful microorganisms, in this embodiment, in order to make the feed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com