A convection dedusting device and smokeless garbage incineration system

A dust removal device and garbage incineration technology, which is applied in combined devices, incinerators, combustion methods, etc., can solve problems such as large amount of domestic garbage composting, difficulty in reaching standards for smoke and dust, soil compaction, and deterioration of groundwater quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

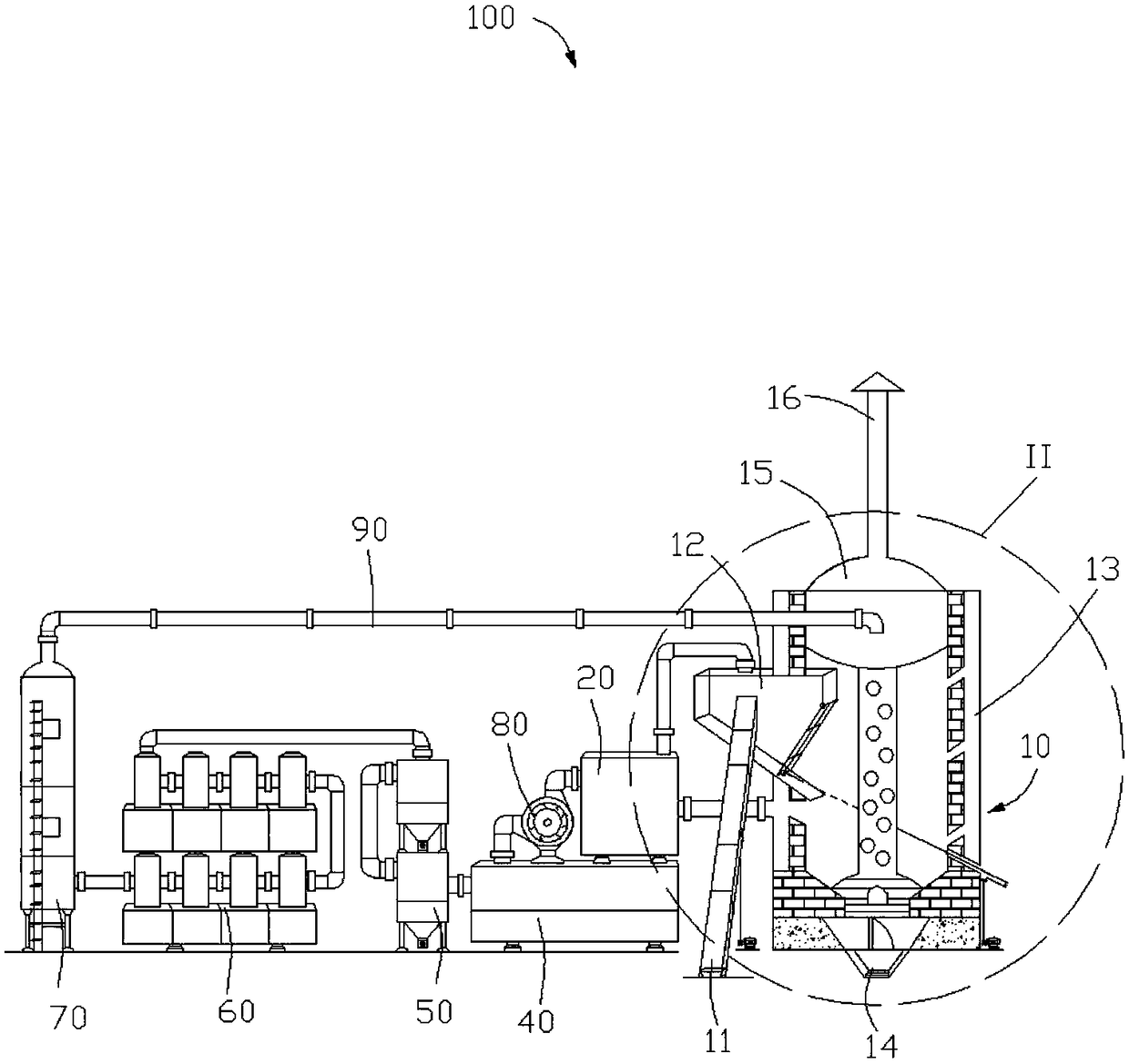

[0022] see figure 1 , in one embodiment of the present invention, a smokeless waste incineration system 100 includes an incinerator 10, a dust interception box 20, a tar treatment chamber 40, a cyclone settling tank 50, a convective dust removal device 60 and a smoke Gas purification tower 70. The incinerator 10 communicates with the dust interception box 20, the tar treatment chamber 40 communicates with the dust interception box 20 through a draft structure 80, the cyclone settling tank 50 communicates with the convection dust removal device 60, and the convection The dust removal device 60 communicates with the flue gas purification tower 70 , and the flue gas purification tower 70 communicates with the incinerator 10 through a smoke exhaust pipe 90 . In the embodiment of the present invention, the ventilation structure 80 is a high-pressure blower.

[0023] Please refer to figure 2 , the incinerator 10 includes a feeding device 11 , a drying chamber 12 , a furnace body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com