Small-sized electronic element double-deck shock absorber based on flat spring

A technology of electronic components and leaf springs, which is applied in the field of double-layer shock absorbers for small electronic components, can solve the problems of discounted shock absorption effect, design stiffness deviation, difficult adjustment, etc., achieve low center of mass, reduce vibration coupling, and reduce size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

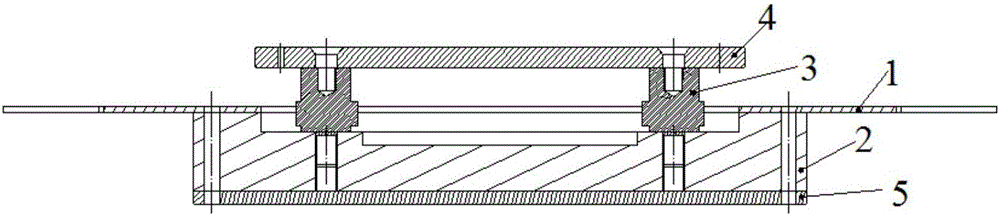

[0032] Such as figure 1 , 2 As shown, the double-layer shock absorber based on small electronic components provided by this embodiment includes a leaf spring 1, an intermediate mass block 2, at least one secondary spring 3 and a mounting plate 4 for installing components to be damped , the mounting plate is located above the leaf spring 1; the leaf spring 1 is provided with a through hole for providing deformation space for the secondary spring 3, and one end of the secondary spring 3 is installed on the mounting The lower end surface of the plate 4; the intermediate mass 2 is installed on the lower side of the leaf spring 1; the other end of the secondary spring 3 passes through the through hole 1-5 on the leaf spring 1 and connects with the The intermediate mass block 2 is connected. Wherein the secondary spring 3 is made of rubber or metal rubber.

[0033] The double-layer shock absorber for small electronic components based on leaf springs provided in this embodiment is...

Embodiment 2

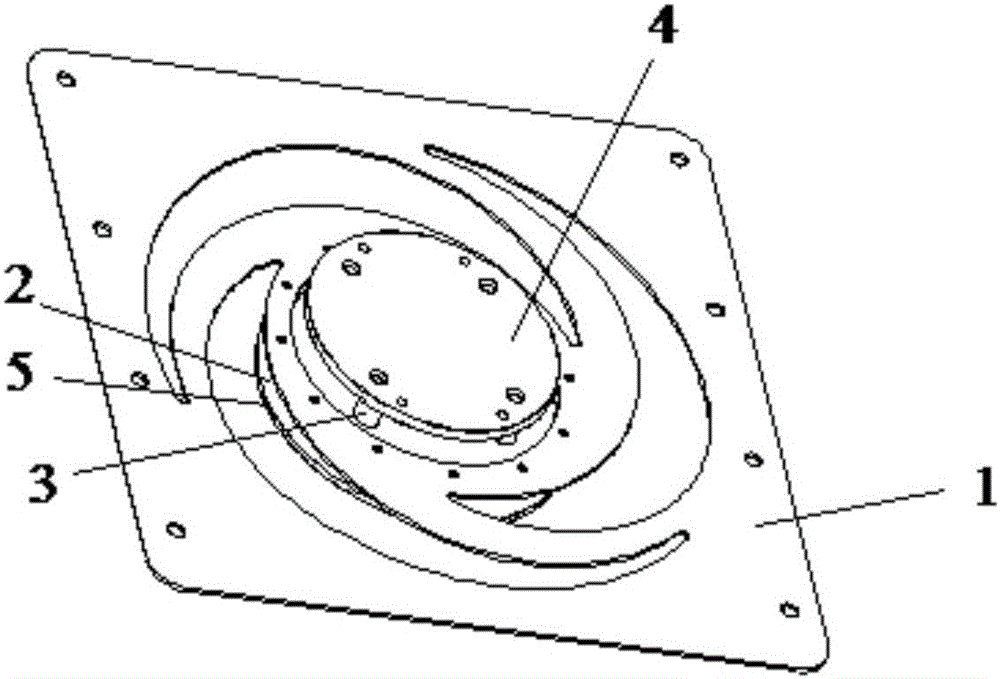

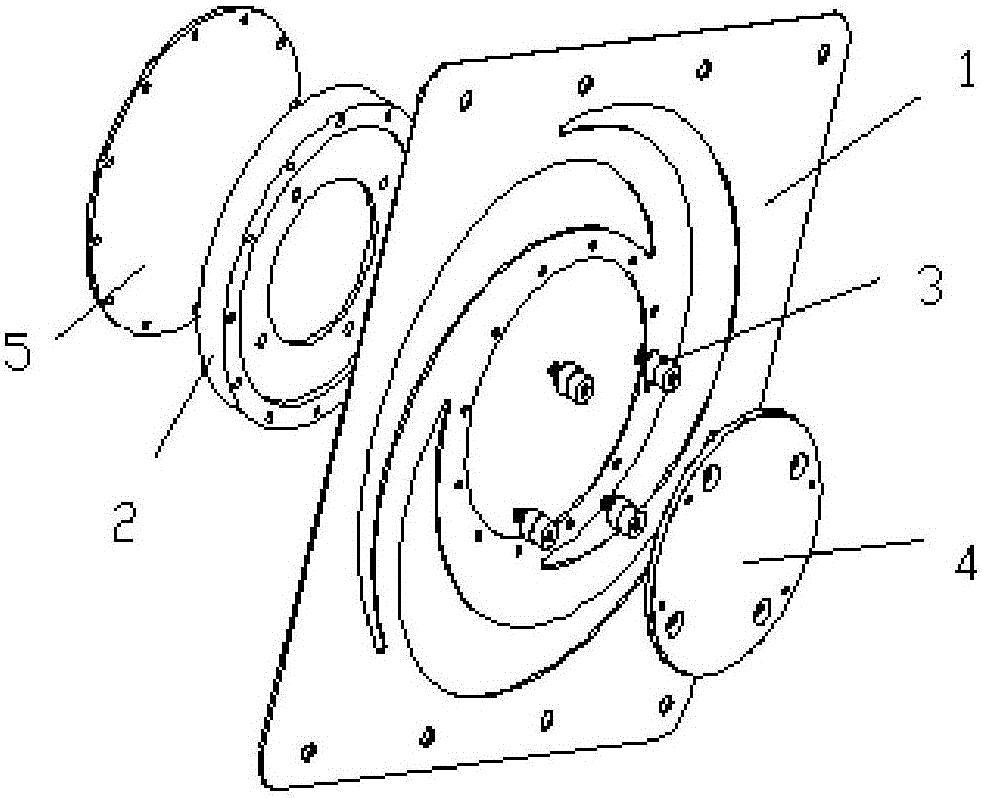

[0036] Such as Figures 3 to 8 As shown, the double-layer shock absorber based on small electronic components provided by this embodiment includes a leaf spring 1, an intermediate mass block 2, at least one secondary spring 3 and a mounting plate 4 for installing components to be damped , the mounting plate is located above the leaf spring 1; the leaf spring 1 is provided with through holes 1-5 for providing deformation space for the secondary spring 3, and one end of the secondary spring 3 is installed on The lower end surface of the mounting plate 4; the intermediate mass 2 is installed on the lower side of the leaf spring 1; the other end of the secondary spring 3 passes through the through hole 1 on the leaf spring 1- 5 is coupled with the intermediate mass 2. It also includes at least one tuning mass 5 mounted on the lower end face of the intermediate mass 2 .

[0037] The adjustment mass 5 wherein can be a disc structure, and the adjustment mass 5 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com