Compressing mechanism and rotary compressor

A compression mechanism and compression chamber technology, applied in the direction of rotary piston machines, rotary piston pumps, machines/engines, etc., can solve the problems of compressor capacity attenuation, refrigerant volume reduction, etc., and achieve high system energy efficiency and operational reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

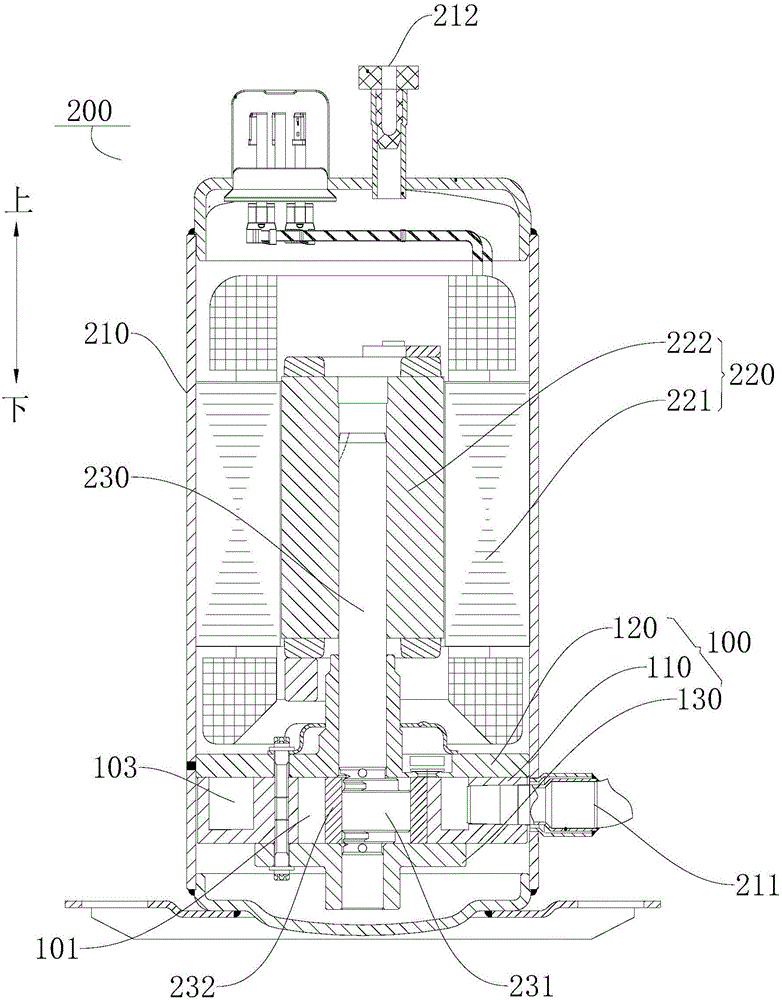

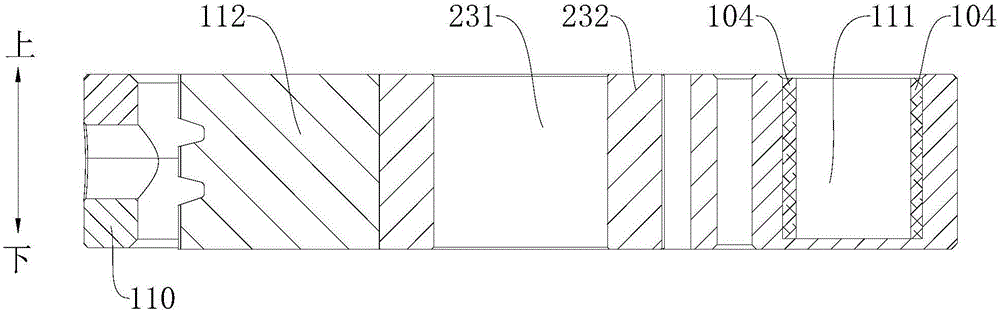

[0047] Such as Figure 1-Figure 5 As shown, in this embodiment, rotary compressor 200 includes housing 210 , motor assembly 220 , crankshaft 230 and compression mechanism 100 . Wherein, the casing 210 has a suction port 211 and an exhaust port 212 , and the motor assembly 220 and the compression mechanism 100 are both arranged in the casing 210 . The compression mechanism 100 may include a cylinder 110, an upper bearing 120 and a lower bearing 130. The cylinder 110 is sandwiched between the upper bearing 120 and the lower bearing 130. The cylinder 110 has a compression chamber 101 and a liquid storage space 111 with an open upper end. The liquid storage chamber 103 is jointly constructed by the liquid storage space 111 and part of the lower end surface of the upper bearing 120 . The compression chamber 101 communicates with the liquid storage chamber 103 , and the liquid storage chamber 103 communicates with the outside through the refrigerant channel 102 . Refrigerant can b...

Embodiment 2

[0052] Such as Figure 6-Figure 7 As shown, the difference from Embodiment 1 is that in this embodiment, the heat insulating member 104 is formed as a profiling plastic part, and the profiling plastic part covers the entire inner wall of the liquid storage chamber 103, which can simulate the liquid storage chamber 103 After injection molding or blow molding, the profiling plastic part is built into the liquid storage chamber 103 so that it is in close contact with the inner wall of the liquid storage chamber 103. When the refrigerant gas flows in the profiling plastic part, due to the contact with the cylinder 110 If the cavities are not in contact, it will also have a good heat insulation effect, thereby improving the suction superheat and improving the energy efficiency and reliability of the rotary compressor 200 .

[0053] This profiled plastic is mainly composed of polyurethane (PU), polyethylene terephthalate (PET, PETE), polybutylene terephthalate (PBT), polyphenylene s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com