Electrically assisted turbocharging system and control method thereof

A technology of turbocharger system and turbocharger, applied in electrical control, engine control, fuel injection control, etc., can solve the problems of insufficient low-speed torque, slow transient response, etc., to improve low-speed torque output and alleviate turbo lag , the effect of meeting the torque demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

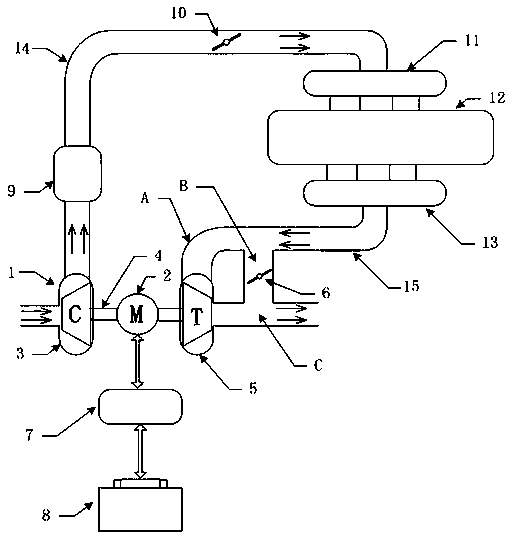

[0037] One end of the electric auxiliary turbocharger 1 of the present invention is installed on the inlet end of the air intake passage 14, and the other end is installed on the outlet end of the air outlet passage 15. The electric auxiliary turbocharger 1 is composed of an auxiliary high-speed motor 2, a compressor 3, a turbine The turbocharger rotating shaft 4, turbine 5, and wastegate valve device 6 are composed. The compressor 3 is installed at the inlet of the air intake, and the auxiliary high-speed motor 2 is installed between the compressor 3 and the turbine 5. The auxiliary high-speed motor 2 rotor, compressor The engine 3 and the turbine 5 are coaxially connected through the turbocharger rotating shaft 4, the stator of the auxiliary high-speed motor 2 is installed on the shell of the electric auxiliary turbocharger 1, and the auxiliary high-speed motor 2 is connected with a storage battery 8 through a power converter 7; An intercooler 9 is installed on the air passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com