Pressing expansion type downhole annular blowout preventer and communication method thereof

A blowout preventer and expansion type technology, applied in the field of blowout prevention technology, can solve the problems of weak automation and danger, and achieve the effects of reducing the total cost, long service life and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

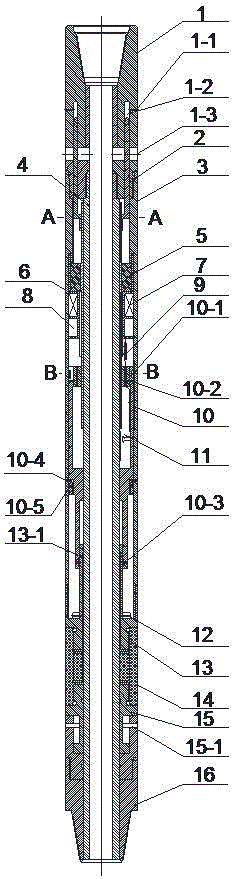

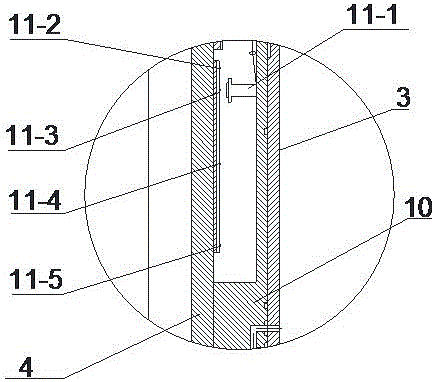

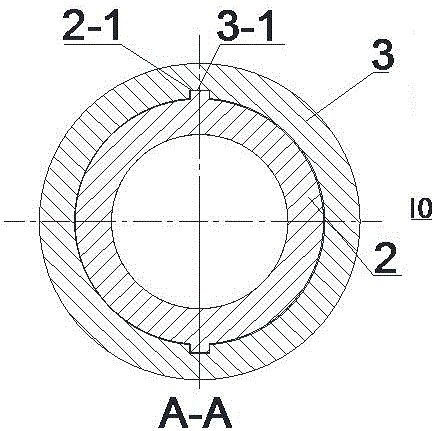

[0035] like figure 1 As shown, a pressure expansion downhole annular blowout preventer includes an upper joint (1), an annular slider (2), an outer sleeve (3), a central sleeve (4), a motor (5), a fixed Cylinder (6), hub (9), pressing slider (10), limit switch (11), check valve (12), upper rubber cylinder seat (13), rubber cylinder (14), lower rubber cylinder seat ( 15) and the lower joint (16); the upper joint (1) and the lower joint (16) are covered with the central cylinder (4) and are fixedly connected with the central cylinder (4) by threads, and the upper joint (1) has an annular chute (1-2) Cooperate with the annular slider (2), the leftmost end of the groove has a vent (1-1), and the upper joint (1) has an annular channel (1-3), the outer sleeve and The upper and lower joints adopt the most convenient threaded connection, which makes the fit more closely. The annular chute of the upper joint cooperates with the annular slider to facilitate the sliding of the slider. T...

specific Embodiment 2

[0036] Based on the device in Embodiment 1, the blowout prevention method of the downhole annular blowout preventer with pressure and expansion is as follows:

[0037] 1. When an overflow is found, the formation high-pressure fluid enters the drill string through the drill bit and flows upward. When the overflow is found, after the well is shut down on the ground, the formation high-pressure liquid enters the drill string through the drill bit and flows upward, so that the downhole blowout prevention tools near the drill bit are closed. , to block the internal channel of the drill string, and at the same time, the formation high-pressure fluid in the wellbore annulus passes through the lower joint of the downhole blowout preventer, and blowout prevention measures need to be taken at this time.

[0038] 2. The control command is issued by the ground control center (a) and transmitted to the encoder (b). The encoder (b) encodes the control command according to Manchester encoding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com