A metallographic etchant for extruded magnesium-lithium alloy and its application method

A magnesium-lithium alloy and metallographic corrosion technology is applied in the field of metallographic etchants for extruded magnesium-lithium alloys, which can solve the problems of blurred metallographic structure, poor corrosion resistance of magnesium-lithium alloys, and difficulty in observation and analysis. The effect of clear and complete metallographic structure and clearly discernible grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A metallographic etchant for an extruded magnesium-lithium alloy is prepared by uniformly mixing 40ml of hydrofluoric acid with a mass fraction of 40%, 20ml of citric acid with a mass fraction of 60%, and 40ml of ethanol with a mass fraction of 98%.

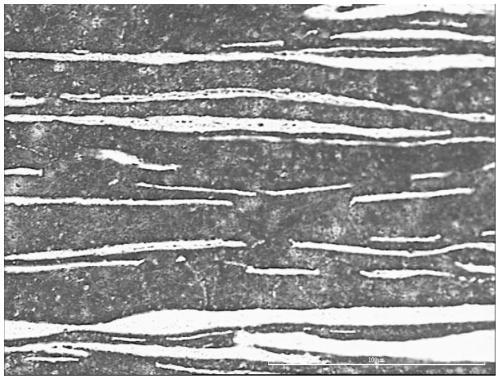

[0024] Specifically, at room temperature, use a plastic straw to absorb the metallographic etchant of the extruded magnesium-lithium alloy described in Example 1 of the present invention, and drop it onto the polished surface of the extruded magnesium-lithium alloy A for metallographic analysis. Corrosion, the metallographic corrosion time is 5-15s, and then clean the eroded extruded magnesium-lithium alloy A with clean water, and use a cotton ball dipped in absolute ethanol to clean the surface of the extruded magnesium-lithium alloy A after cleaning. Wipe it, and then use a hair dryer to dry its surface, so that the metallographic corrosion of the extruded magnesium-lithium alloy A can be realized. The metallographic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com