Ferritic stainless steel having high resistance to intergranular corrosion

A ferritic and corrosive technology, which is applied in the field of ferritic stainless steel with excellent intergranular corrosion resistance, can solve the problems of increasing the preparation cost of welding structures and complicated welding procedures, so as to inhibit intergranular corrosion and prevent intergranular corrosion. Inter-corrosion, preventing the effect of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The compositions of Comparative Examples and Inventive Examples of the present invention are shown in Table 1 below.

[0069] Ferritic stainless steel material having the component contents in Table 1 below and containing P and S as impurities of 0.001% by weight or less was subjected to solution annealing at 1300°C for 10 minutes, and then sensitized at 500°C. heat treatment for 2 hours. This heat treatment is performed to simulate the driving environment of conventional steel after welding.

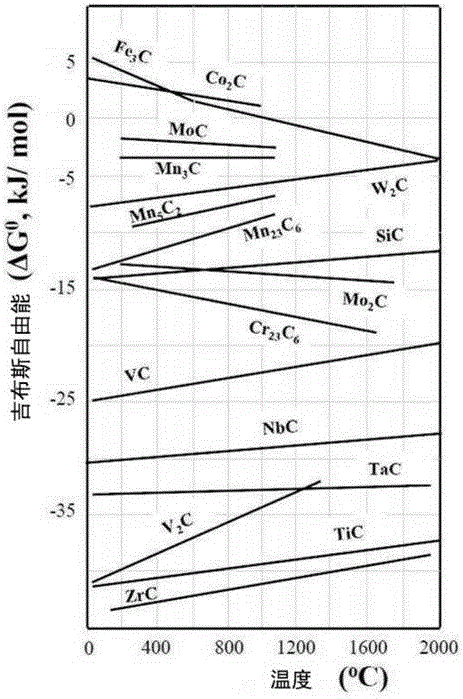

[0070] When welding ferritic stainless steel, it will be heated to near the melting temperature of stainless steel (above about 1300°C). The stainless steel materials of Ti and Nb, which are carbide stabilizing elements, are sensitized to induce intergranular corrosion.

[0071] Table 1

[0072]

[0073] (‘-’: present as a trace element)

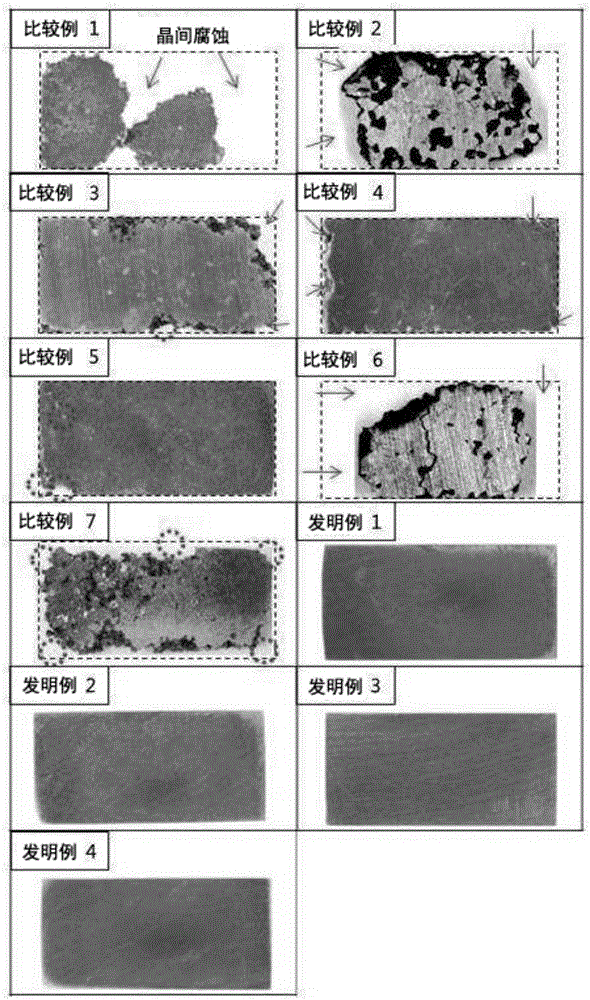

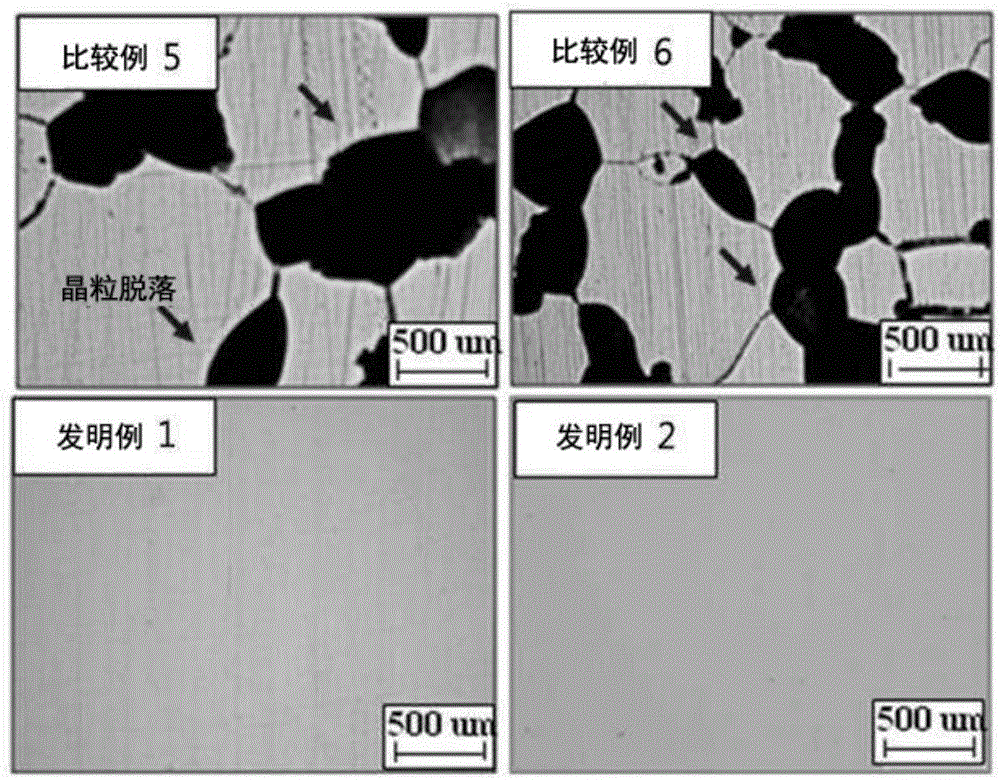

[0074] After the ferritic stainless steel materials having the above-mentioned component contents of the comparative examples and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com