Quenching medium and quenching method for steel cord

A technology of cooling medium and cooling method, applied in the direction of quenching agent, quenching device, furnace type, etc., can solve the problems of endangering human health, easy slagging of lead liquid, high labor intensity, etc., and achieve good product performance, low cost, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

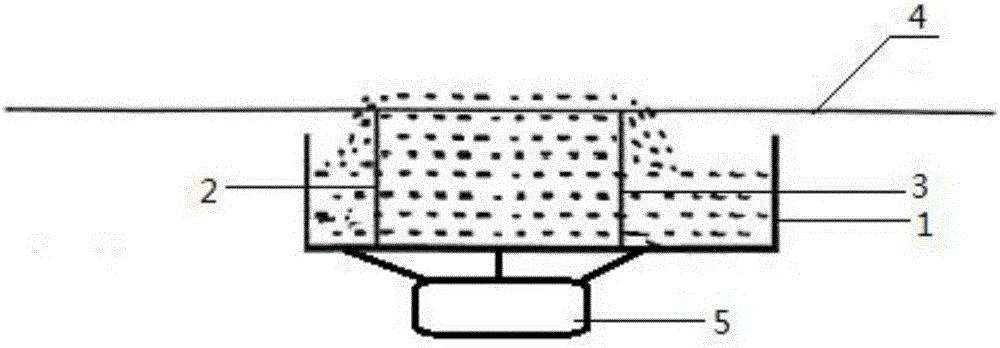

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

[0024] The quenching cooling medium for steel cords of the present invention is composed of the following components in mass percentage: 2-5% sodium carboxymethyl cellulose, 15-20% sodium polyacrylate, 3-5% additives and the balance is water .

[0025] The additives of the quenching cooling medium in the present invention include defoamers, antirust agents, bactericides and the like.

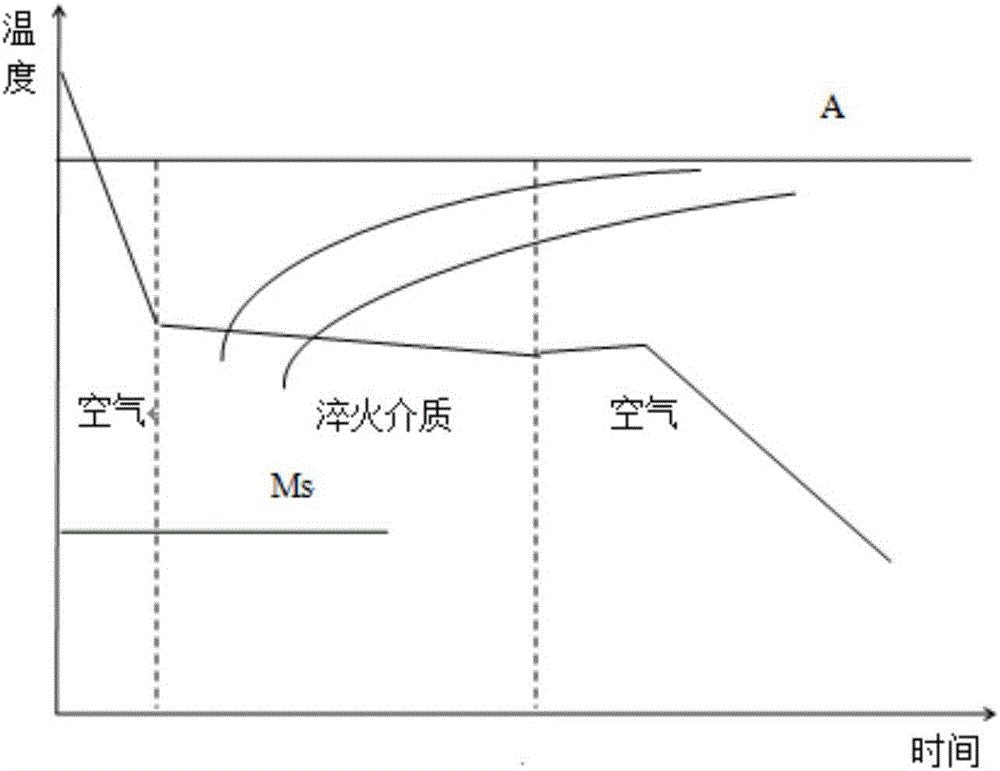

[0026] The quenching cooling medium of the present invention has a very slow cooling rate of about 10°C / s in the high temperature zone (500°C-800°C), and a very fast cooling rate of about 50°C / s in the low temperature zone (below 500°C).

[0027] The physical and chemical properties of the quenching cooling medium that the present invention is used for steel cord are as shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com