Wood or paper-based packing box integrated spraying manufacture method

A manufacturing method and packaging box technology, applied to paper coating, coating, paper, etc., can solve the problems of inner package quality degradation, moisture-prone, moldy, etc., and achieve the effects of prolonging service life, ensuring quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

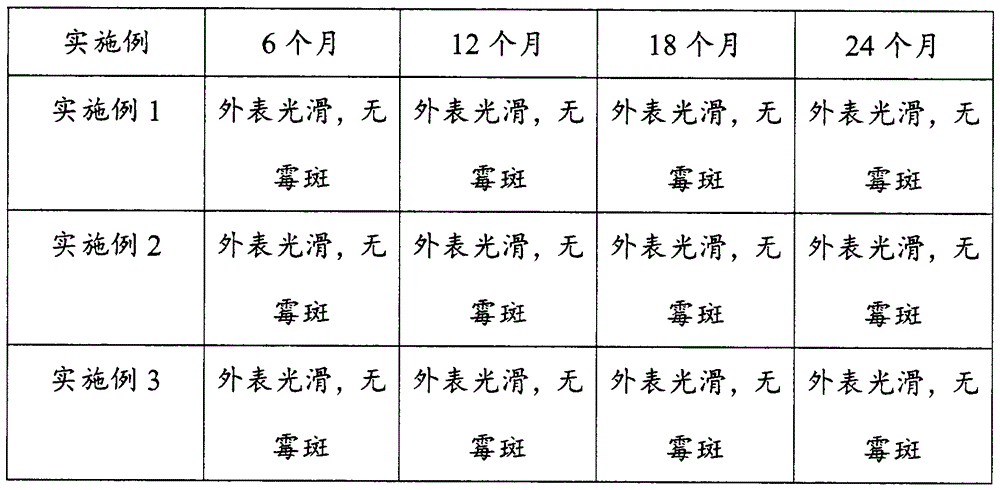

Examples

Embodiment 1

[0026] An integrated spraying manufacturing method for wooden packaging boxes, based on integrated spraying equipment,

[0027] The integrated spraying equipment includes a box body, a conveyor belt located in the box body, a drive motor for driving the conveyor belt, a spraying mechanism and a drying mechanism, the box body includes a spraying area and a drying area, the spraying mechanism is located in the spraying area, and the spraying The mechanism is composed of a feeding pump, a feeding main pipe, several branch pipes and several nozzles at the ends of the branch pipes. The nozzles are located directly above the conveyor belt. The drying mechanism adopts far-infrared heating.

[0028] The spraying manufacturing method comprises the following steps:

[0029] (1) Processing of semi-finished wood boards for packaging boxes;

[0030] (2) Pretreatment of the semi-finished wooden board of the packaging box: process the semi-finished product of the packaging box in a dry atmo...

Embodiment 2

[0035] An integrated spraying manufacturing method for paper packaging boxes, based on integrated spraying equipment,

[0036] The integrated spraying equipment includes a box body, a conveyor belt located in the box body, a drive motor for driving the conveyor belt, a spraying mechanism and a drying mechanism, the box body includes a spraying area and a drying area, the spraying mechanism is located in the spraying area, and the spraying The mechanism is composed of a feeding pump, a feeding main pipe, several branch pipes and several nozzles at the ends of the branch pipes. The nozzles are located directly above the conveyor belt. The drying mechanism adopts far-infrared heating.

[0037] The spraying manufacturing method comprises the following steps:

[0038] (1) Semi-finished cardboard processing of packaging boxes;

[0039] (2) Pretreatment of the semi-finished cardboard of the packaging box: process the semi-finished packaging box in a dry atmosphere for 3-5 hours, and...

Embodiment 3

[0050] An integrated spraying manufacturing method for paper packaging boxes, based on integrated spraying equipment,

[0051] The integrated spraying equipment includes a box body, a conveyor belt located in the box body, a drive motor for driving the conveyor belt, a spraying mechanism and a drying mechanism, the box body includes a spraying area and a drying area, the spraying mechanism is located in the spraying area, and the spraying The mechanism is composed of a feeding pump, a feeding main pipe, several branch pipes and several nozzles at the ends of the branch pipes. The nozzles are located directly above the conveyor belt. The drying mechanism adopts far-infrared heating.

[0052] The spraying manufacturing method comprises the following steps:

[0053] (1) Semi-finished cardboard processing of packaging boxes;

[0054] (2) Pretreatment of the semi-finished cardboard of the packaging box: process the semi-finished packaging box in a dry atmosphere for 3-5 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com