Method for utilizing metal organic skeleton to carry out efficient catalytic activation on persulfate or peroxymonosulfate to process organic wastewater

A metal-organic framework and persulfate technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of unrecyclable iron sludge and easy failure of ferrous ions, etc., and achieve Broad practical application prospects, short catalytic time and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

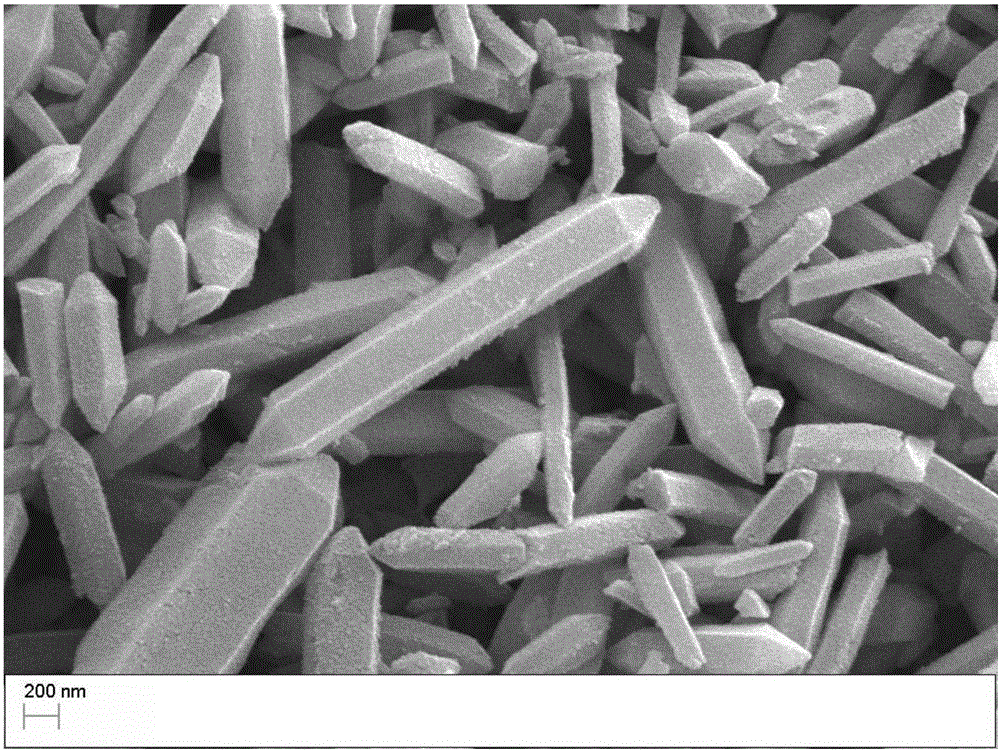

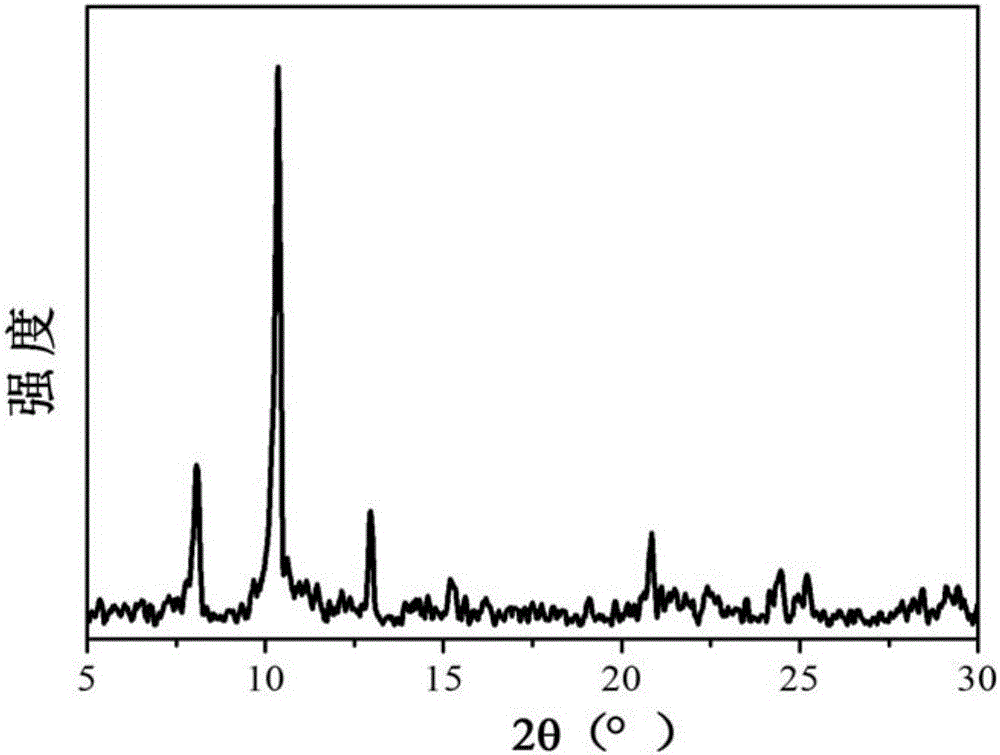

[0029] In this implementation case, the MIL-88A catalyst was prepared under the preparation condition of 2h / 65°C to study the degradation effect of MIL-88A on OG.

[0030] (1) Preparation of metal-organic framework MIL-88A: Weigh 0.9744g (1mol) fumaric acid and 2.2722g (1mol) FeCl 3 ·6H 2 O was dissolved in 42ml of deionized water, and after stirring for 1 hour, the solution was transferred to a 100ml polytetrafluoroethylene-lined reaction kettle, and the reaction kettle was placed in a blast drying oven, and reacted at 65°C for 2h Finally, the reactor was taken out, and the reactor was cooled to room temperature. After the reaction kettle was cooled, the reacted mixture was taken out, and centrifuged at 9000rpm for 10 minutes to obtain a light yellow solid, then the light yellow solid was poured into a beaker, washed with ethanol for 3 hours, centrifuged, and then washed with deionized water for 3 hours. This was repeated twice, and after obtaining a solid, it was placed in...

Embodiment example 2

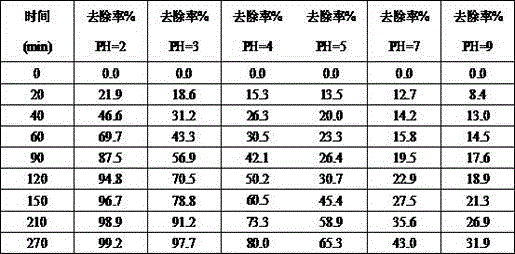

[0041] In this implementation case, MIL-88A prepared under the preparation condition of 2h / 65°C was used as the catalyst to study Na 2 S 2 o 8 and OG in different molar ratios (nNa 2 S 2 o 8 / nOG=20, 40, 60, 80, 100) on the catalytic activation reaction.

[0042] (1) The preparation method of metal-organic framework MIL-88A is the same as step (1) in Example 1;

[0043] (2) Prepare 100mmol / L Na 2 S 2 o 8 Solution, the OG solution of 10mmol / L is standby;

[0044] (3) Use the Erlenmeyer flask as the reactor, add 100mmol / LNa into the reactor 2 S 2 o 8 2mL and 10mmol / LOG 1mL (nNa 2 S 2 o 8 / nOG=20) and deionized water to keep the volume of the solution in the reactor at 100mL, and at the same time, add 0.03g metal-organic framework material MIL-88A to the reactor, adjust the pH=2.8, and place the Erlenmeyer flask at 300rpm In the shaker, the reaction is carried out under normal temperature conditions, and sampling and analysis are carried out at fixed points;

[0...

Embodiment example 3

[0054] This implementation case uses MIL-88A prepared under the preparation conditions of 2h / 65°C as the catalyst to study the dosage of MIL-88A (0.005g, 0.01g, 0.02g, 0.03g, 0.04g, 0.05g, 0.06g) for The effect of the catalytic activation reaction.

[0055] (1) The preparation method of metal-organic framework MIL-88A is the same as step (1) in Example 1;

[0056] (2) Prepare 100mmol / L Na 2 S 2 o 8 Solution, the OG solution of 10mmol / L is standby;

[0057] (3) Use the Erlenmeyer flask as the reactor, add 100mmol / LNa into the reactor 2 S 2 o 8 6mL and 10mmol / LOG 1mL (nNa 2 S 2 o 8 / nOG=60) and deionized water to keep the volume of the solution in the reactor at 100mL, and at the same time, add 0.005g metal-organic framework material MIL-88A to the reactor, adjust the pH=2.8, and place the Erlenmeyer flask at 500rpm In the shaker, the reaction is carried out under normal temperature conditions, and sampling and analysis are carried out at fixed points;

[0058] (4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com