Metal-chalcogen semiconductor material as well as preparation method and application thereof

A semiconductor and chalcogen technology, applied in the field of metal-chalcogen semiconductor materials, and its preparation, can solve the problems of difficult to achieve large-scale industrial production, poor controllability, complex nanocrystal preparation process, etc., to achieve thermoelectric value and energy conversion high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

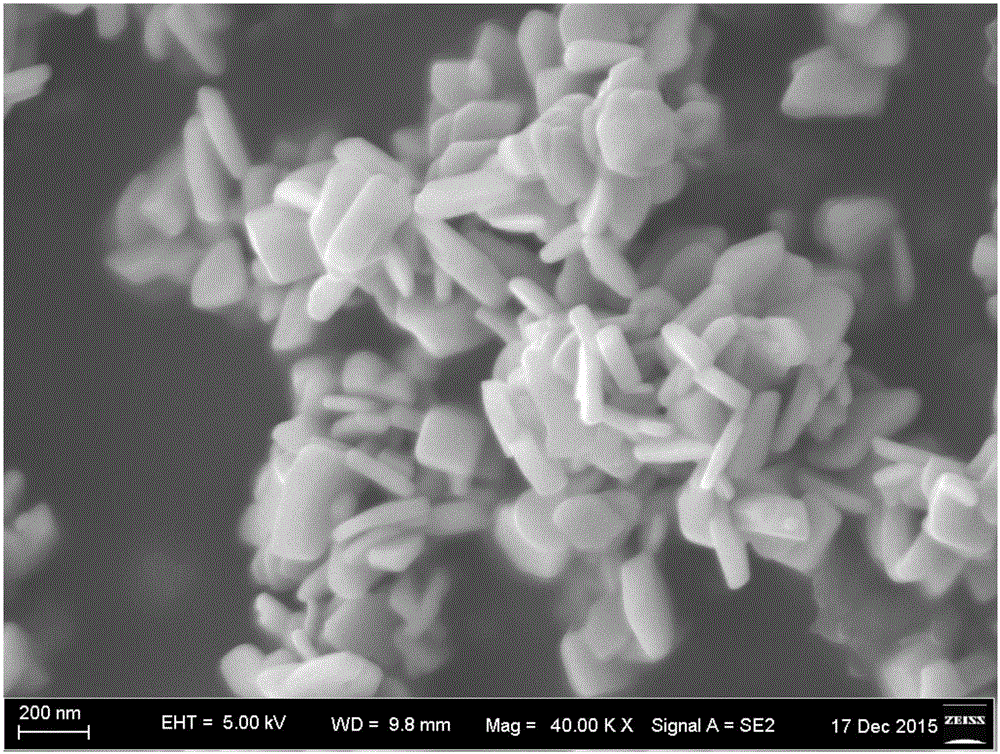

[0067] A kind of SnSe ultra-thin nanosheet, its scanning electron microscope picture is as follows figure 1 As shown, it can be seen from the figure that the size of the SnSe ultra-thin nanosheet is 50-200 nanometers, and the thickness is 1-10 nanometers.

[0068] Its preparation method comprises the following steps:

[0069] (1) Add 4g of Se elemental powder and 8g of SnCl in the reaction vessel 2 Powder and 30mL of oleylamine are mixed to obtain a precursor solution;

[0070] (2) Under stirring conditions, add 50 mL of hexamethyldisilamine (HMDS) to the precursor solution, heat to 150 ° C, and carry out hydrothermal reaction under stirring conditions for 8 hours to obtain the reaction product;

[0071] (3) The reaction product is centrifuged at 10000rpm for 10min. After the centrifugation ends, the supernatant is removed, and the precipitate is washed several times with ethanol and acetone mixture (mixed in any proportion) or acetone. suspended in water or other organic s...

Embodiment 2

[0074] A SnSe ultrathin nanosheet, the SnSe ultrathin nanosheet has a size of 50-200 nanometers and a thickness of 1-10 nanometers.

[0075] Its preparation method comprises the following steps:

[0076] (1) Add 0.001g of Se elemental powder and 10g of SnCl to the reaction vessel 2 The powder and 10mL of oleylamine are mixed to obtain a precursor solution;

[0077] (2) Add 0.01 mL of hexamethyldisilazine (HMDS) to the precursor solution under stirring conditions, heat to 80°C, and carry out hydrothermal reaction under stirring conditions for 12 hours to obtain the reaction product;

[0078] (3) The reaction product is centrifuged at 15000rpm for 30min. After the centrifugation ends, the supernatant is removed, and the precipitate is washed several times with ethanol and acetone mixture (mixed in any proportion) or acetone. suspended in water or other organic solvents).

[0079] After calculation, the yield of the SnSe ultra-thin nanosheets is 92%.

Embodiment 3

[0081] A SnSe ultrathin nanosheet, the SnSe ultrathin nanosheet has a size of 50-200 nanometers and a thickness of 1-10 nanometers.

[0082] Its preparation method comprises the following steps:

[0083] (1) Add 10g of Se elemental powder and 0.001g of SnCl to the reaction vessel 2 The powder and 1000mL of oleylamine are mixed to obtain a precursor solution;

[0084] (2) Add 100 mL of hexamethyldisilamine (HMDS) to the precursor solution under stirring conditions, heat to 300° C., and carry out hydrothermal reaction under stirring conditions for 12 hours to obtain the reaction product;

[0085] (3) The reaction product is centrifuged at 1000rpm for 5min. After the centrifugation ends, remove the supernatant, and the precipitate is washed several times with ethanol and acetone mixture (mixed in any proportion) or acetone. suspended in water or other organic solvents).

[0086] After calculation, the yield of the SnSe ultra-thin nanosheets is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com