An air-conditioning unit for film-type lng ship containment system

A technology for LNG ships and air-conditioning units, applied in the field of air-conditioning units, can solve the problems of high cost, large capacity and small number of air-conditioning units, and achieve the effects of reducing design and manufacturing costs, realizing energy-saving operation, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

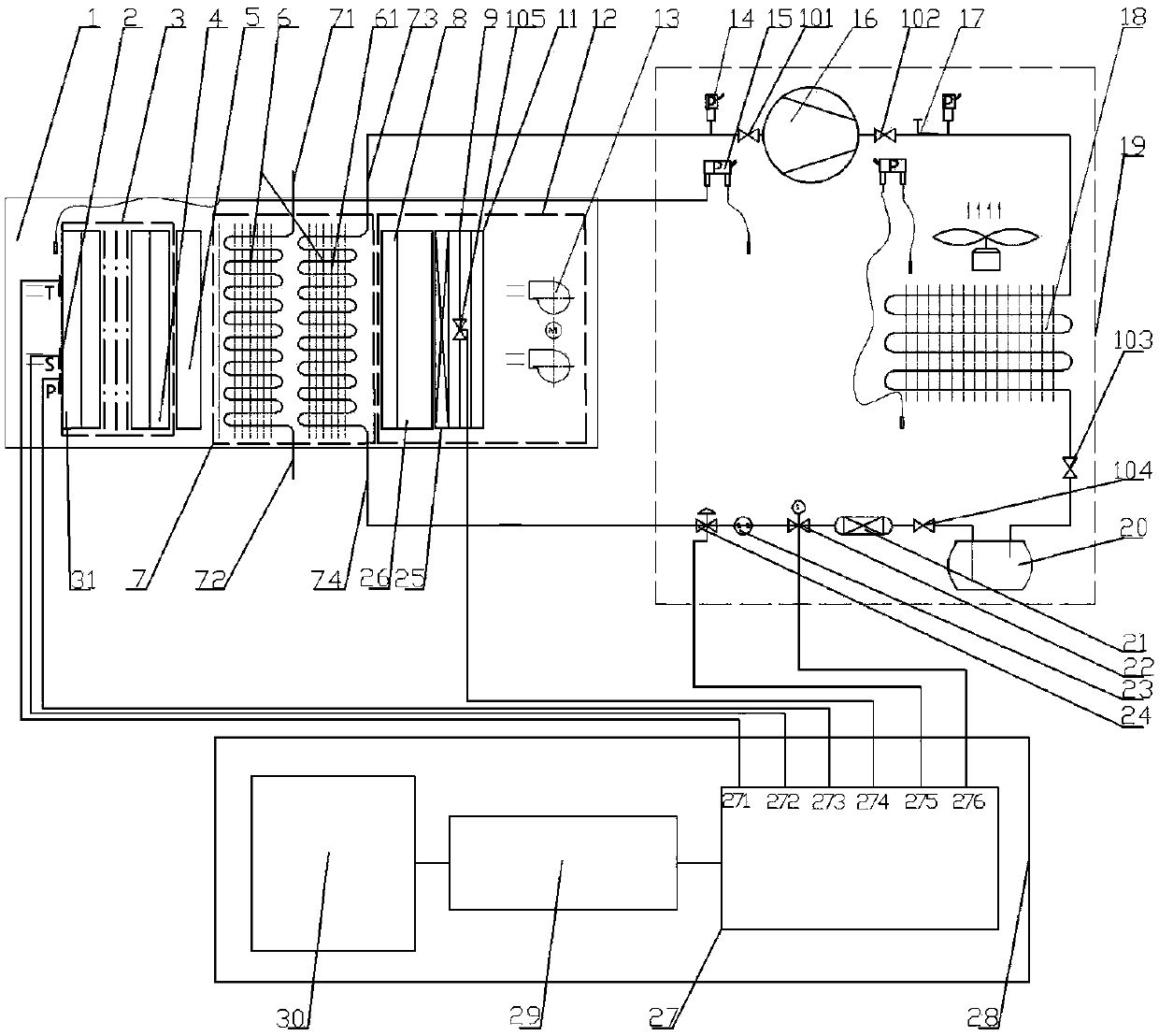

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

[0011] The present invention takes the 600kW modular air-conditioning unit of the LNG ship cargo hold construction platform as an embodiment, and now the 600kw unit is divided into two sets of modular units of 200kW and 400kW, wherein 200KW is composed of a refrigeration, heating and filtering system, and 400KW is composed of two The same module composition as the 200KW module. This treatment not only facilitates modular and standardized design and manufacture, reduces manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com