Carbon fiber wheel rim

A carbon fiber and carbon fiber layer technology, which is applied to wheels, wheels made of non-metallic materials, transportation and packaging, etc., can solve the problems of not easy to carry, consume more energy, and high cost of carbon fiber rims, and achieve the effect of reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

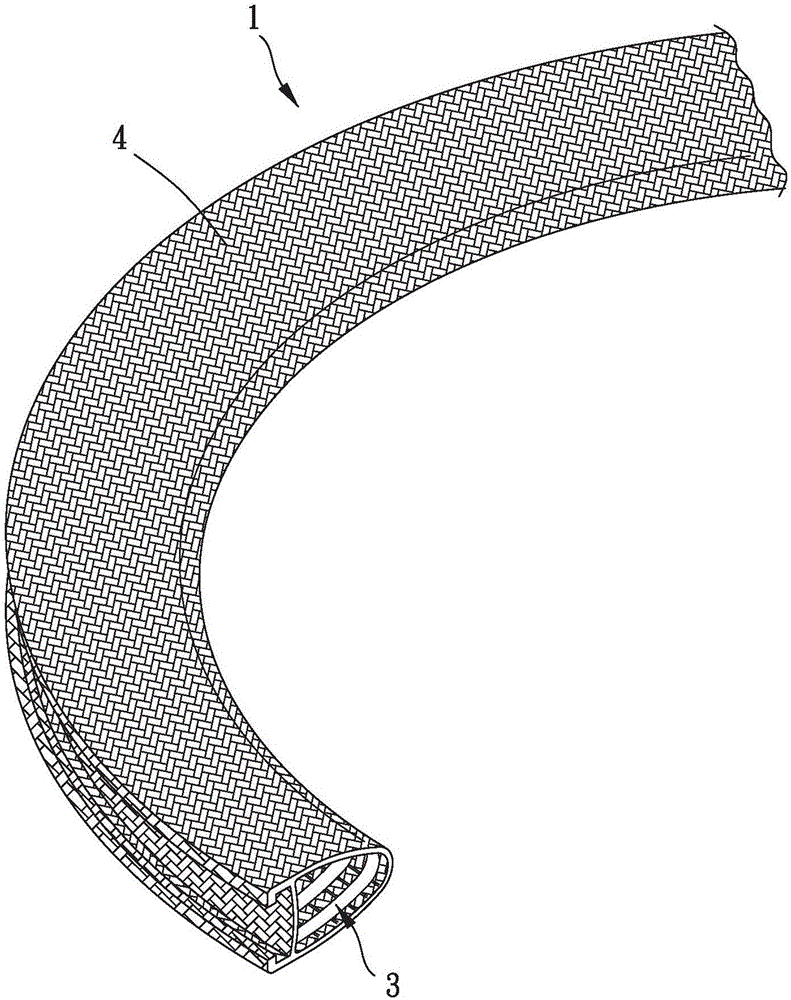

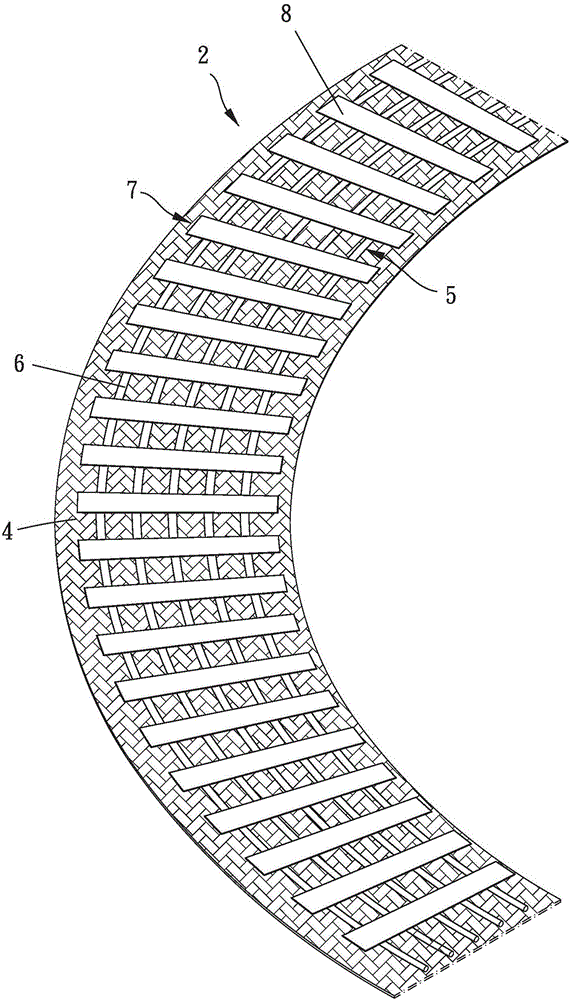

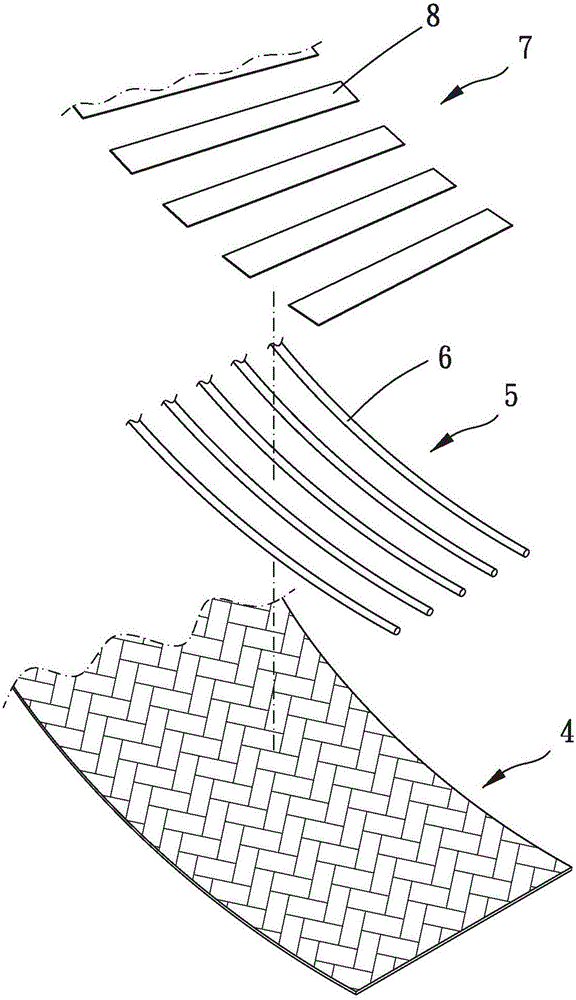

[0025] Please refer to Figure 1 to Figure 5 , which shows a preferred embodiment of the present invention, the carbon fiber rim 1 of the present invention includes: a body 2 . The main body 2 is tubular and ring-shaped and defines a center of a circle. The main body 2 defines a tubular space 3. The main body 2 is at least formed by superimposing a first carbon fiber layer 4 and a second carbon fiber layer 5. The first carbon fiber layer 4 The carbon fiber layer 4 is located on the outer surface of the body 2 and is a woven carbon fiber cloth. The second carbon fiber layer 5 is located between the first carbon fiber layer 4 and the tubular space 3. The second carbon fiber layer 5 includes at least one carbon fiber Cloth strips 6 , the at least one carbon fiber cloth strip 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com