Subsurface type feeding mold cavity plate

A latent, feeding mold technology, applied in the structural field of plastic product molds, can solve problems such as affecting the molding accuracy of products, reduce the probability of bumps, avoid assembly errors, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with accompanying drawing.

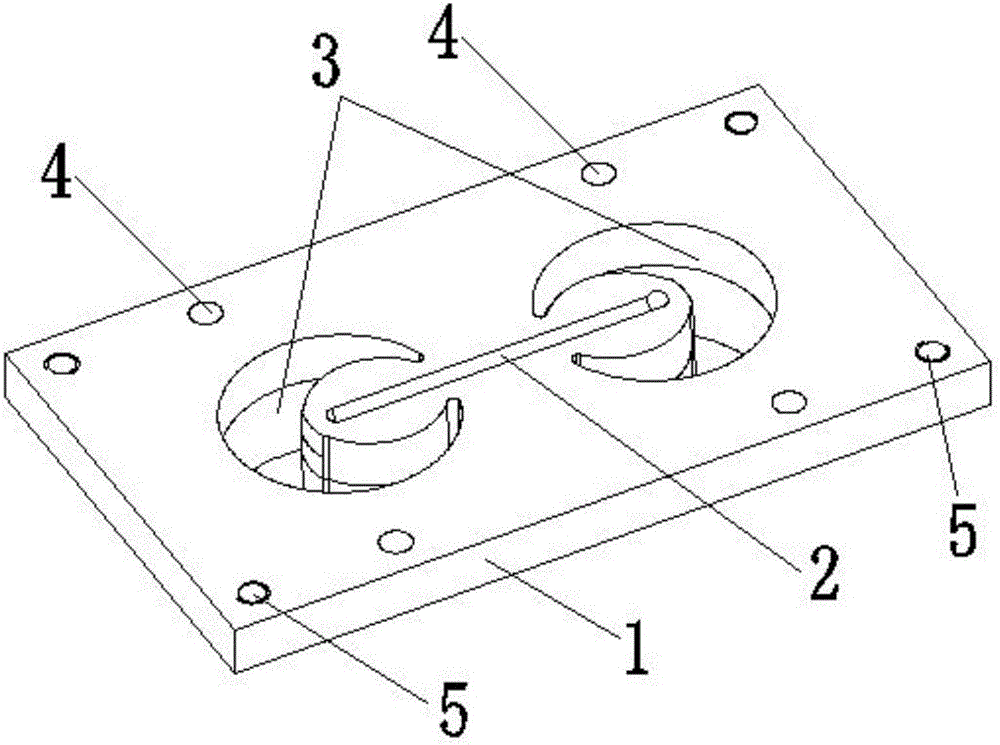

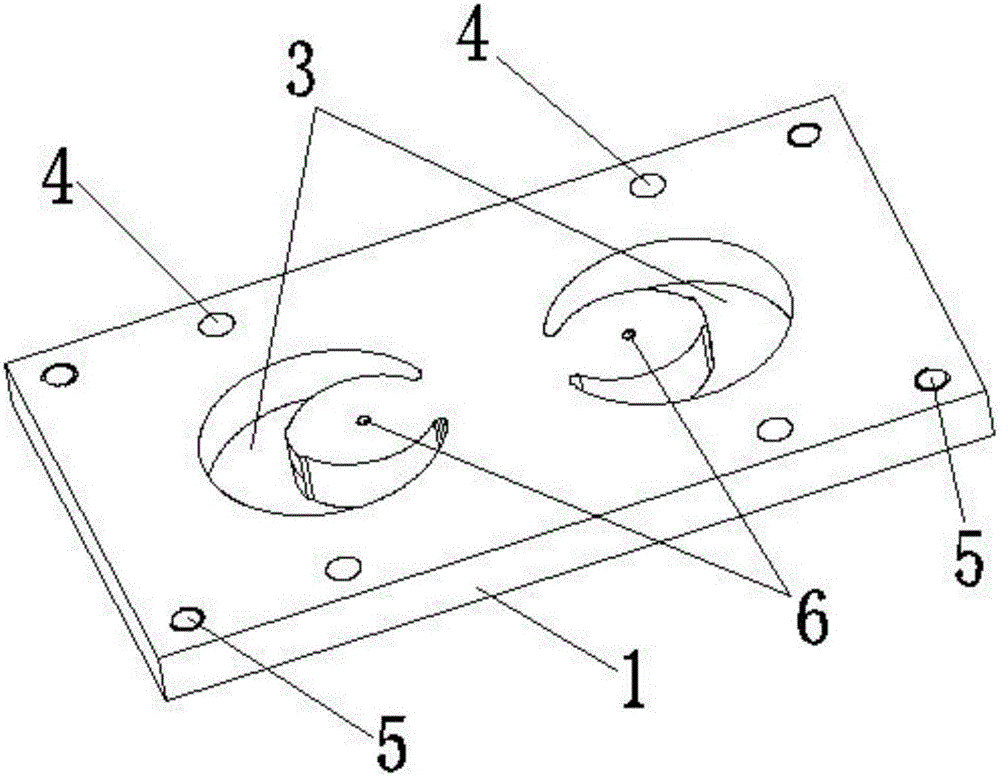

[0020] The latent feeding die cavity plate of the present invention, as attached figure 1 , 2 As shown, it includes a cavity plate main body 1 in the shape of a cuboid; the middle part of the upper end surface of the cavity plate main body 1 is provided with a transverse flow channel 2; the cross section of the transverse flow channel 2 is semicircular; the cavity plate main body 1 is provided with two symmetrical insert cavities 3; the insert cavities 3 are crescent-shaped; the insert cavities 3 vertically penetrate the cavity plate main body 1; the two insert cavities 3 are located in the transverse flow channel 2 on the left and right sides; the cavity plate main body 1 is also provided with two left and right symmetrical latent feed inlets (shown in the figure); the two latent feed inlets respectively The insert cavity 3 communicates with the transverse flow channel 2; the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com