Rubber pipe cutting device based on improvement of saw blade cooling effect

A technology of heat dissipation effect and cutting device, applied in metal processing and other directions, can solve the problems of poor heat dissipation of saw blades and troublesome operation, and achieve the effect of overcoming poor heat dissipation, small occupied space and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

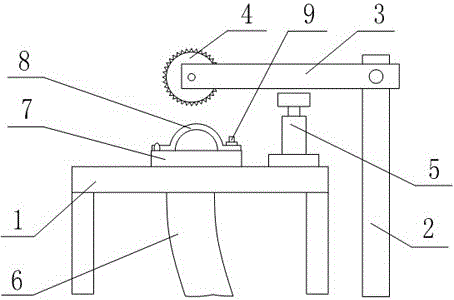

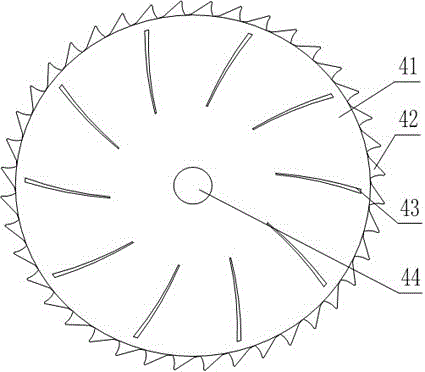

[0037] Such as Figure 1 to Figure 4 As shown, the rubber hose cutting device based on improving the heat dissipation effect of the saw blade includes a frame 1, and two fixing mechanisms are symmetrically arranged on the frame 1, and the fixing mechanism includes a fixing block 7 arranged on the frame 1, and the fixing block 7 One end is hinged with an arc-shaped fixing piece 8, and the other end is provided with a threaded hole. The arc-shaped fixing piece 8 is provided with a through hole matched with the threaded hole. The bolt 9 passes through the through hole and is fixed in the threaded hole. It also includes a column 2, a column A mechanical arm 3 is hinged at the top of the mechanical arm 3, a motor is arranged in the mechanical arm 3, a saw blade 4 connected to the motor is arranged at the non-articulated end of the mechanical arm 3, and a cylinder 5 cooperating with the mechanical arm 3 is provided on the frame 1 The saw blade 4 includes a disc carrier 41, a sawtoot...

Embodiment 2

[0039] Such as Figure 1 to Figure 4 As shown, the present embodiment is based on Embodiment 1, and the frame 1 is provided with a through groove under the saw blade 4, and the through groove is connected with a collection bag 6; the collection bag 6 can be a plastic bag or a cloth bag ; The fixed block 7 is set as a threaded surface; The cylinder 5 can be a hydraulic cylinder or a piston cylinder; The frame 1, the mechanical arm 3 and the column 2 are made of hard aluminum alloy; 431 is a curved surface structure; adjacent grooves 431 are connected by a smooth convex surface; the radial width of the slit 43 gradually increases from one end of the mounting hole 44 to one end of the sawtooth 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com