Blank taking manipulator of annular heating furnace

A technology of billet taking manipulator and annular heating furnace, which is applied in the field of manipulators, can solve the problems of shortening the service life of parts, complex structure, equipment impact and noise, etc., and achieve the reduction of station conversion time, flexible movement trajectory, and adjustment of movement trajectory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

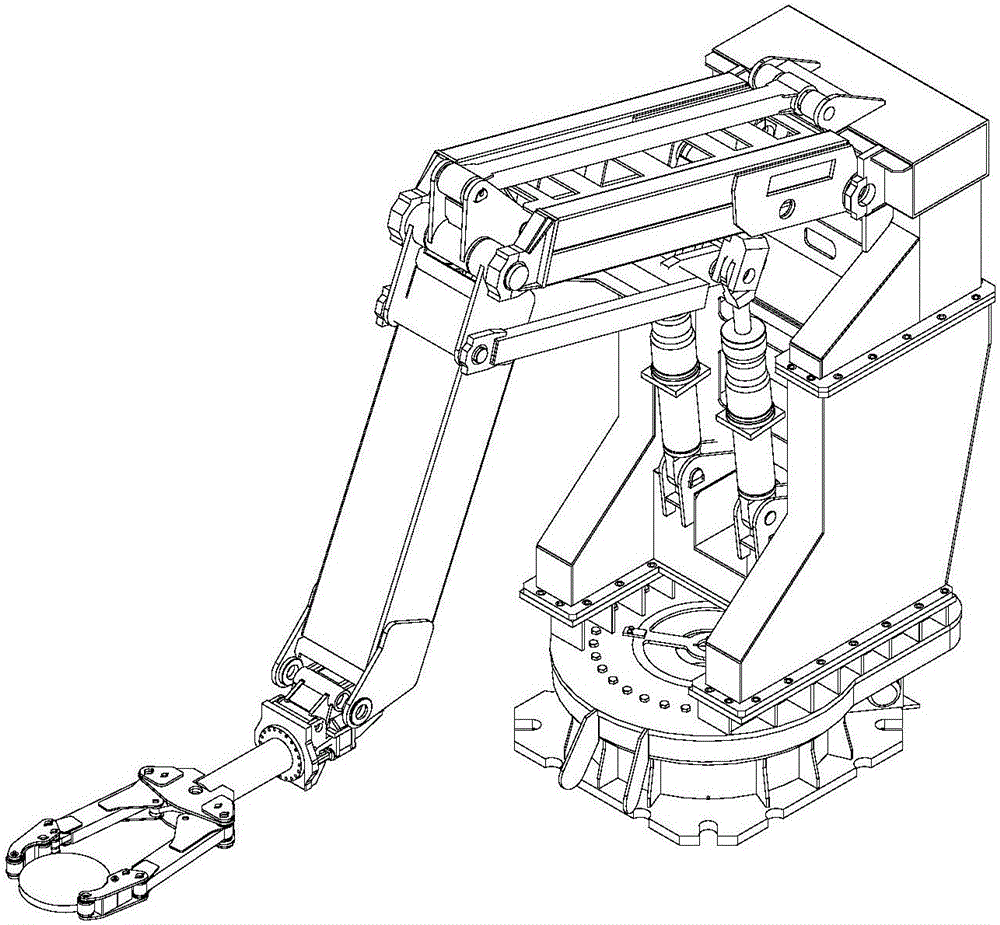

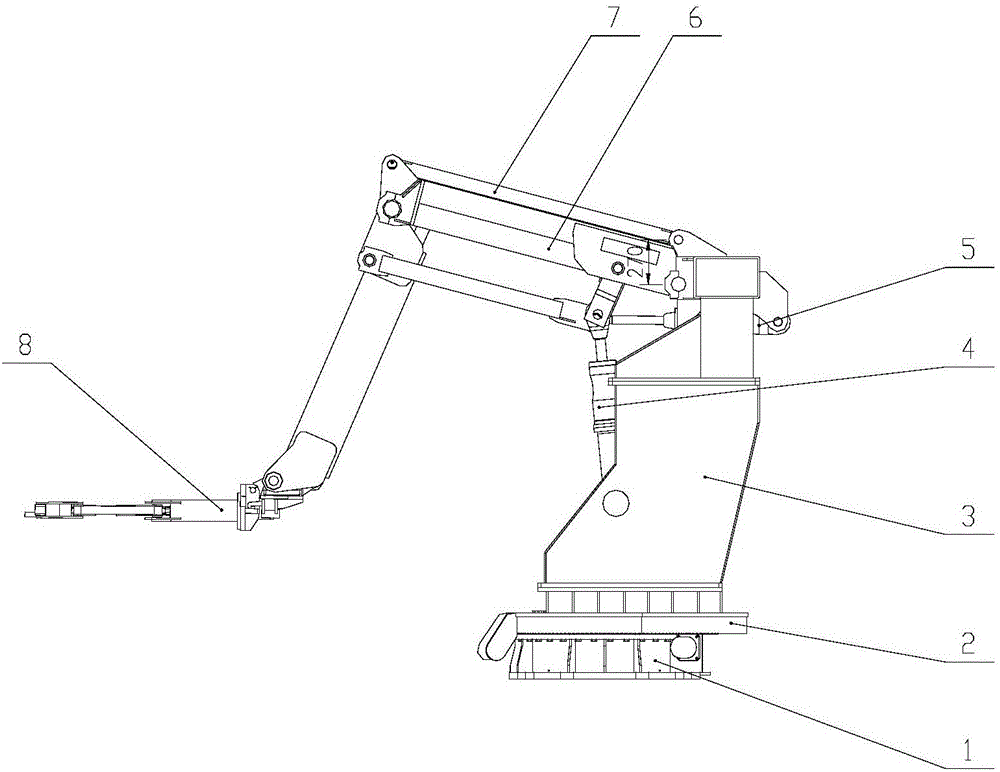

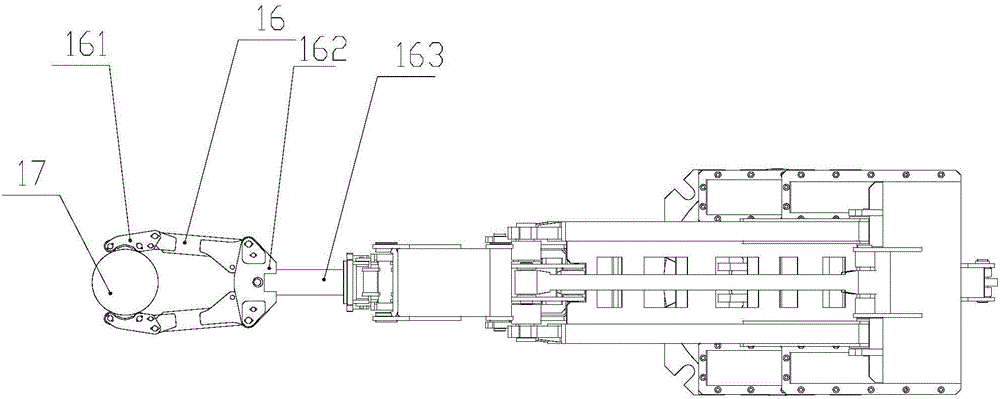

[0020] like Figure 1~4 As shown, this embodiment includes a base 1, a frame 3, a rotary drive mechanism (not shown in the figure) respectively arranged on the frame 3, a rotary mechanism 2, a horizontal drive mechanism 5, a vertical drive mechanism 4, and an upper pull rod 7 , pull down rod 6, first connecting rod 9, first push rod 10, second push rod 11, second connecting rod 12, third connecting rod 13, connecting block 14, moving arm 8;

[0021] The rotating mechanism 2 is arranged on the bottom of the frame 3, the rotating mechanism 2 is located on the base 1, the rotating driving mechanism drives the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com