Robot intelligent rolling and edge covering system and robot intelligent rolling and edge covering method

A robot intelligence, rolling hemming technology, applied in the direction of metal processing equipment, feeding device, positioning device, etc., can solve the problems of hemming difficulties, large land occupation, high cost, etc., to achieve short working cycle, great flexibility, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

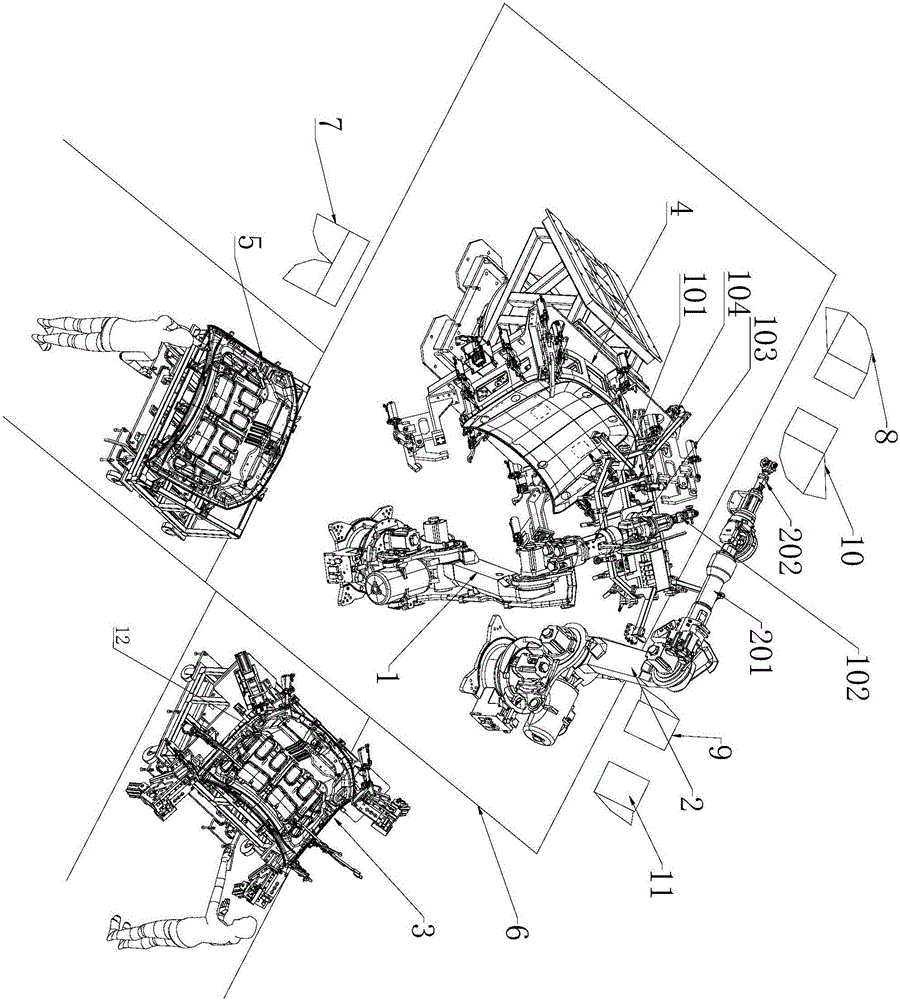

[0035] Such as figure 1 As shown, a robot intelligent rolling hemming system of the present invention includes a robot A1 for rolling operations and workpiece handling, and a robot B2 for rolling operations. Both robots are six-degree-of-freedom robots, and keep a distance Relatively arranged, the robot A1 is provided with an upper piece platform 3 on one side along the X direction, and the opposite side of the upper piece platform 3 is provided with a workbench 4, and the side of the robot A1 opposite to the robot B2 is provided with a lower piece platform 5 ;

[0036] The robot intelligent rolling hemming system is also equipped with a safety fence 6, and the outer periphery of the safety fence 6 is respectively arranged with a main control cabinet 7, a robot A power supply cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com