A method for measuring the pore size of a separation membrane

A measurement method and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of membrane filament real pore size performance error, long production cycle, complex production, etc., and achieve high testing efficiency, The effect of short sample preparation cycle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

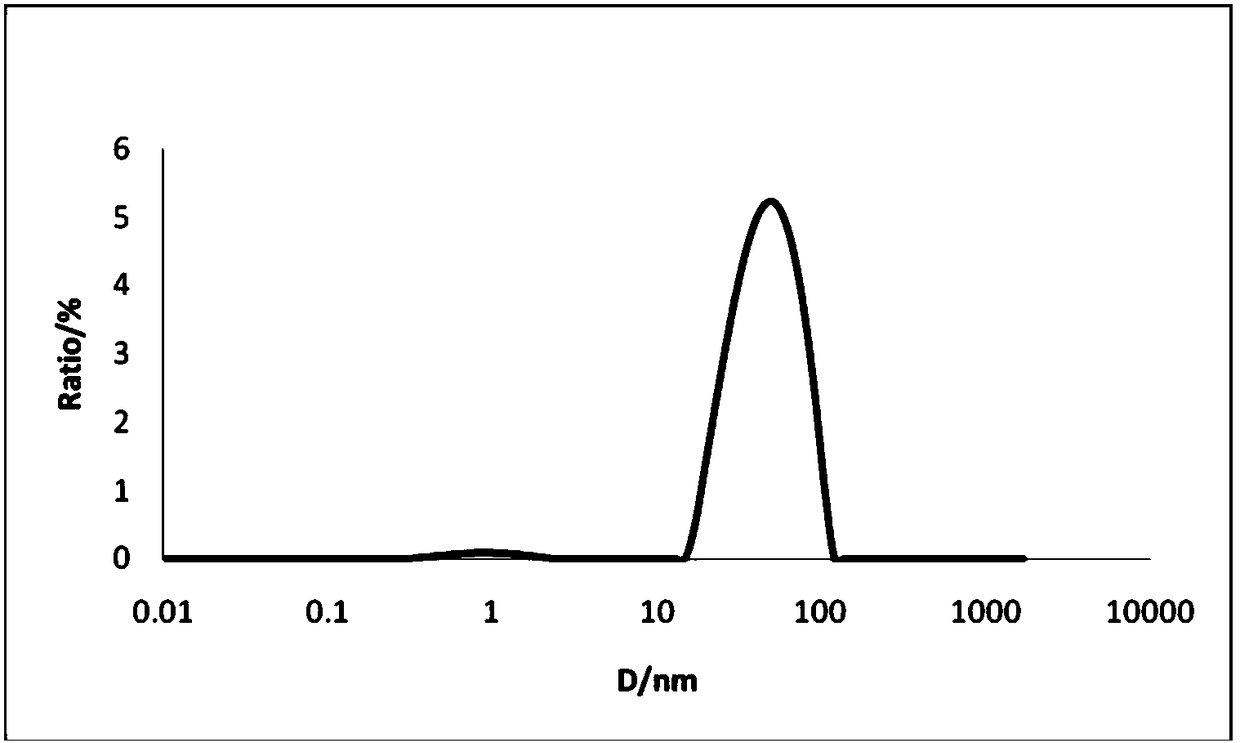

[0045] Test the pore size parameters of hollow fiber membranes made of polyvinylidene fluoride (PVDF)

[0046] (1) Cut the separation membrane to be tested into small fragments of 5 mm long and put it into a container filled with alcohol, and place the container in a vacuum device to evacuate and saturate it for 4 hours until the membrane pores are filled with alcohol solution;

[0047] (2) Take out the separation membrane segment full of alcohol in the membrane hole from the alcohol solution, put it into a density meter equipped with alcohol solution and weigh its volume V;

[0048] (3) Take out the separation membrane segment after weighing the volume, wipe off the residual alcohol solution on the surface of the separation membrane and put it into a glass sample bottle;

[0049] (4) Put the glass sample bottle into the glass test tube, put the glass test tube into the low-field nuclear magnetic resonance instrument, the magnet strength is 0.52T, the center frequency of the a...

Embodiment 2

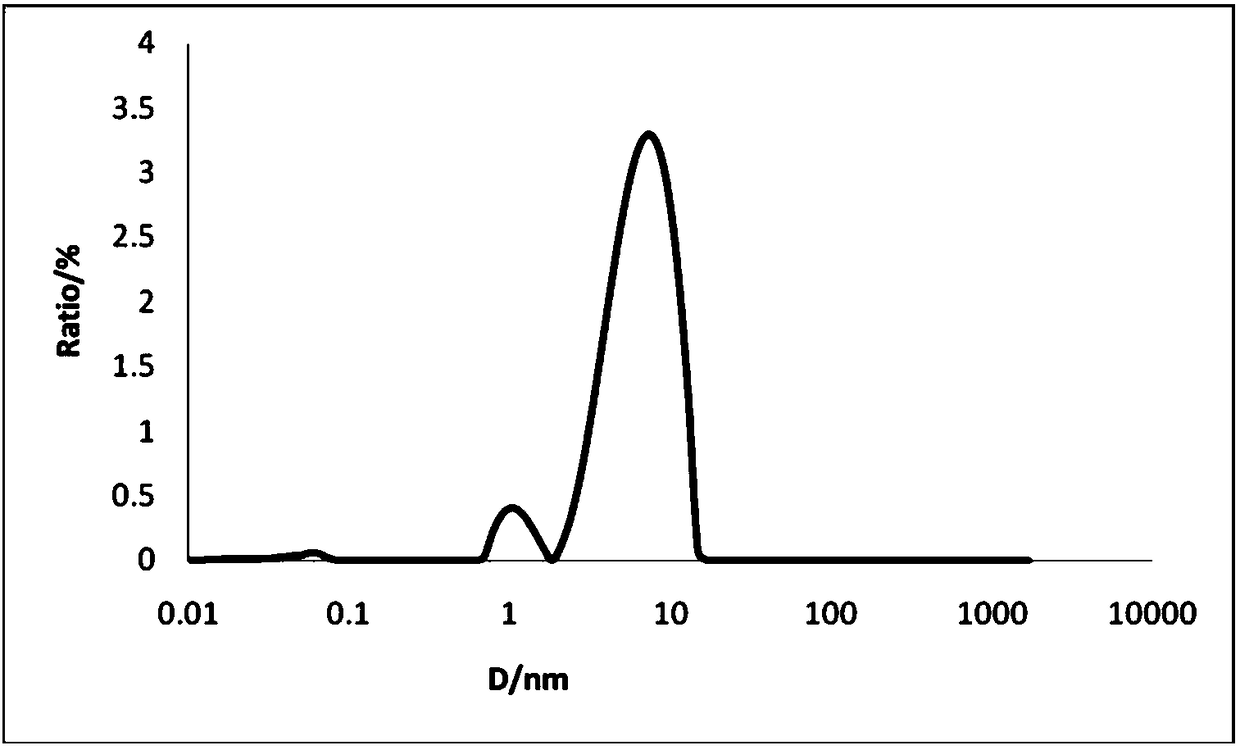

[0072] Test the pore size parameters of hollow fiber membranes made of polyethersulfone (PES)

[0073] (1) Cut the separation membrane to be tested into small fragments of 5 mm long and put it into a container filled with isopropanol, and place the container in a vacuum device to evacuate and saturate for 4 hours until the membrane pores are filled with isopropanol;

[0074] (2) Take out the separation membrane segment filled with isopropanol from the water in the membrane hole, put it into a density meter equipped with water and weigh its volume V;

[0075] (3) Take out the separation membrane segment after weighing the volume, wipe off the residual water on the surface of the separation membrane and put it into a glass sample bottle;

[0076] (4) Put the glass sample bottle into the glass test tube, put the glass test tube into the low-field nuclear magnetic resonance instrument, the magnet strength is 0.52T, the center frequency of the adjustment nuclear magnetic resonance ...

Embodiment 3

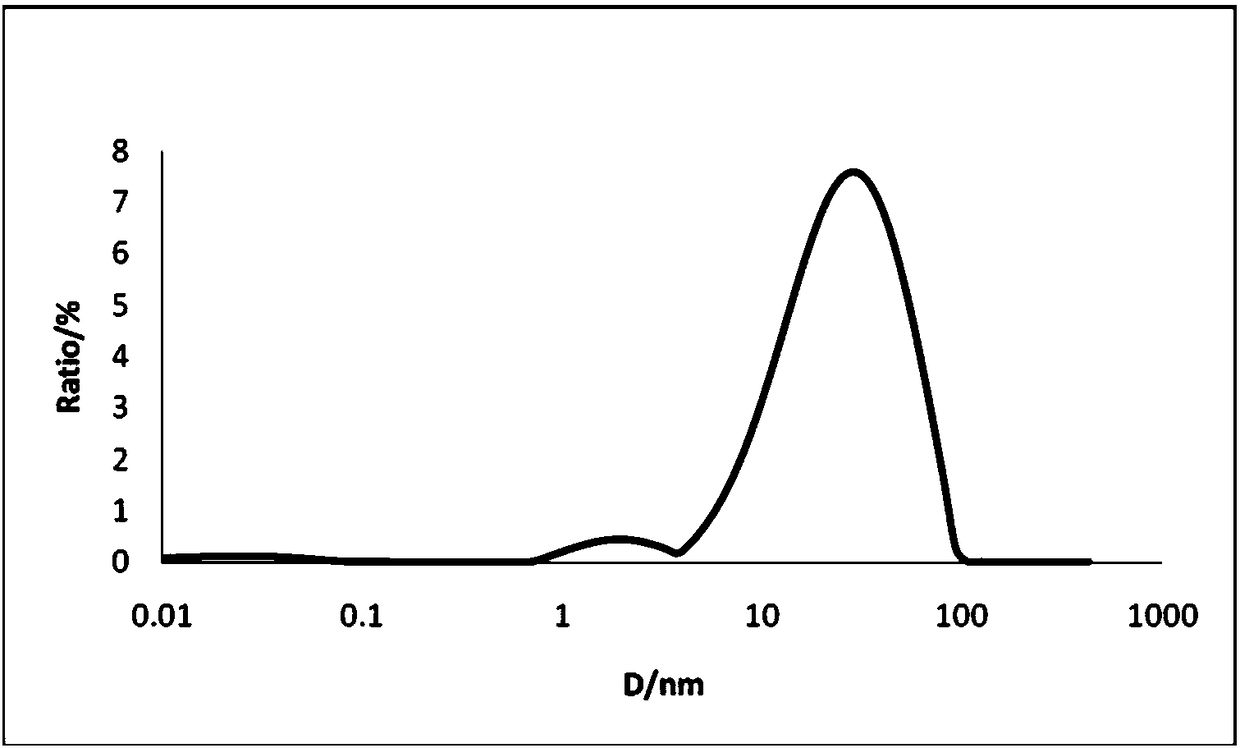

[0079] Test the pore size parameters of polyvinyl chloride (PVC) hollow fiber membranes

[0080] (1) Cut the separation membrane to be tested into small pieces of 5 mm long and put it into a container filled with distilled water, place the container in a vacuum device to evacuate and saturate it for 4 hours, until the membrane pores are filled with distilled water;

[0081] (2) Take out the separation membrane segment full of distilled water in the membrane hole from the distilled aqueous solution, put it into a density meter equipped with distilled water and weigh its volume V;

[0082] (3) The separation membrane segment after weighing the volume is taken out, and the residual distilled water solution on the surface of the separation membrane is dried and put into a glass sample bottle;

[0083] (4) Put the glass sample bottle into the glass test tube, put the glass test tube into the low-field nuclear magnetic resonance instrument, the magnet strength is 0.52T, the center f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com