New technological method for screening redried tobacco stems

A technology of re-cured tobacco and new technology, which is applied in chemical instruments and methods, tobacco, filter and sieve, etc. It can solve the problems of high waste content of long-stem products, long-distance management requirements, easy blockage of vibrating sieve holes, etc., and achieves improved sieving Divided into process quality benefit, large enterprise economic benefit, and the effect of preventing mildew loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

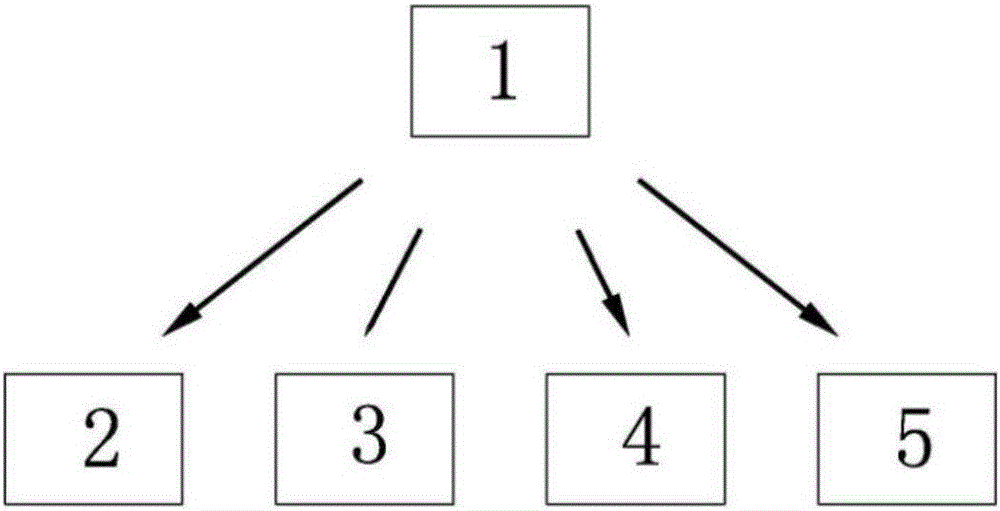

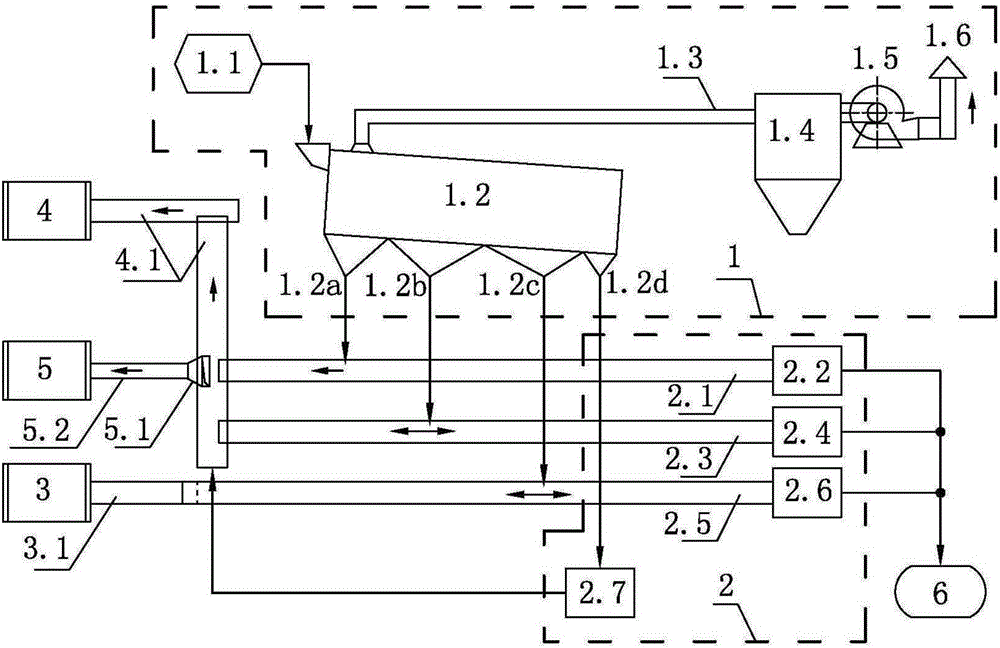

[0054] 1. The five-sided sieve 1.2 is used as the core technical equipment for the screening of re-cured tobacco stems, and the corresponding auxiliary equipment bag filter equipment 1.2-1.6 ( figure 2 , Figure 6 , Figure 7 ), which constitutes the re-cured tobacco stem screening function module 1, which can realize the technological function of screening the re-cured tobacco stems into four kinds of materials including fine short stems, short stems, long stems and stalks;

[0055] 2. With the quantitative bagging scale as the main equipment, it is equipped with corresponding auxiliary conveying equipment ( figure 2 ), which constitutes the stalk product bag packaging module 2, to realize the process functions of carrying out quantitative bagging 2.2, 2.4 and 2.6 to the thin short stalks, short stalks and long stalks; The process function of bagging or basketting 2.7 at the head;

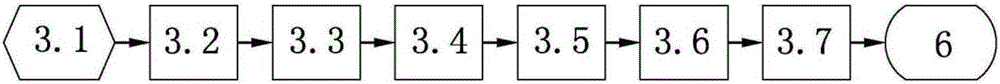

[0056] 3. The main equipment is roller table electronic scale, vibrating roller table, hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com