Corrugated interlocking armoring machine roller shaping conduction band mechanism

An armoring machine and tape guide technology, which is applied in the field of roller shaping and guide tape mechanism of corrugated interlocking armoring machine, can solve the problems of product roundness, large machine noise, large heat generation, etc., and achieve maximum linear speed improvement, convenience and observation And the effect of cleaning and frictional calorific value is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with specific embodiments in conjunction with the accompanying drawings

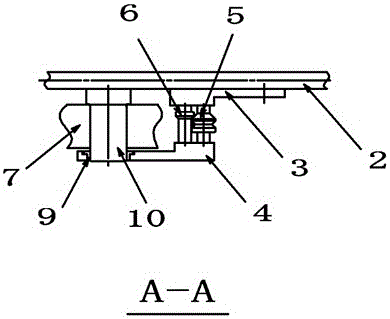

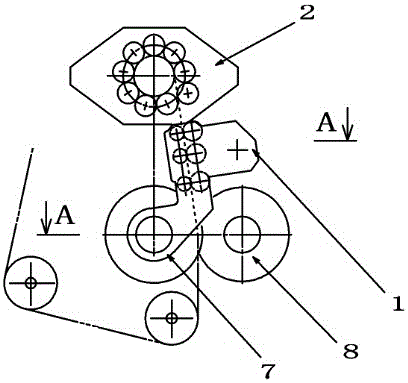

[0010] Such as figure 1 , figure 2 The new structure of corrugated interlocking armoring machine roller shaping guide belt shown is composed of shaping guide belt mechanism 1, winding forming mechanism 2, guide belt fixing plate 3, steering fixing plate 4, active pressing roll 7, driven pressing Roller 8, driven press roll shaft 10, its shaping guide belt mechanism 1 is set between the winding forming mechanism 2, active pressing roll 7, driven pressing roll 8, installed under the winding forming mechanism 2 A guide belt fixing plate 3, and a direction adjustment fixing plate 4 is arranged in parallel with the guide belt fixing plate 3, wherein three pairs of V-groove tapered edge shaping shaft rollers 5 and belts are installed between the guide belt fixing plate 3 and the direction adjustment fixing plate 4 Cone edge shaping suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com