Detection device and detection method for measuring loss degree of aggregate to contact part

A technology for contacting parts and detection devices, applied in measuring devices, material weighing, analyzing materials, etc., can solve problems such as equipment wear, economic loss and waste of equipment and equipment, and save resources, increase production capacity, and infer operating life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

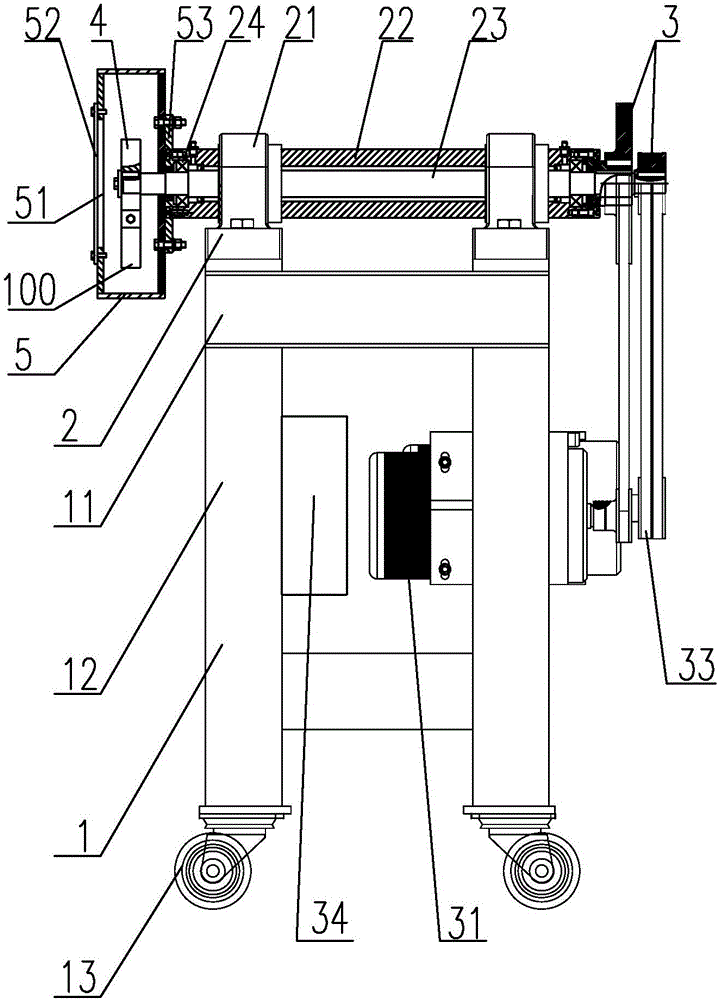

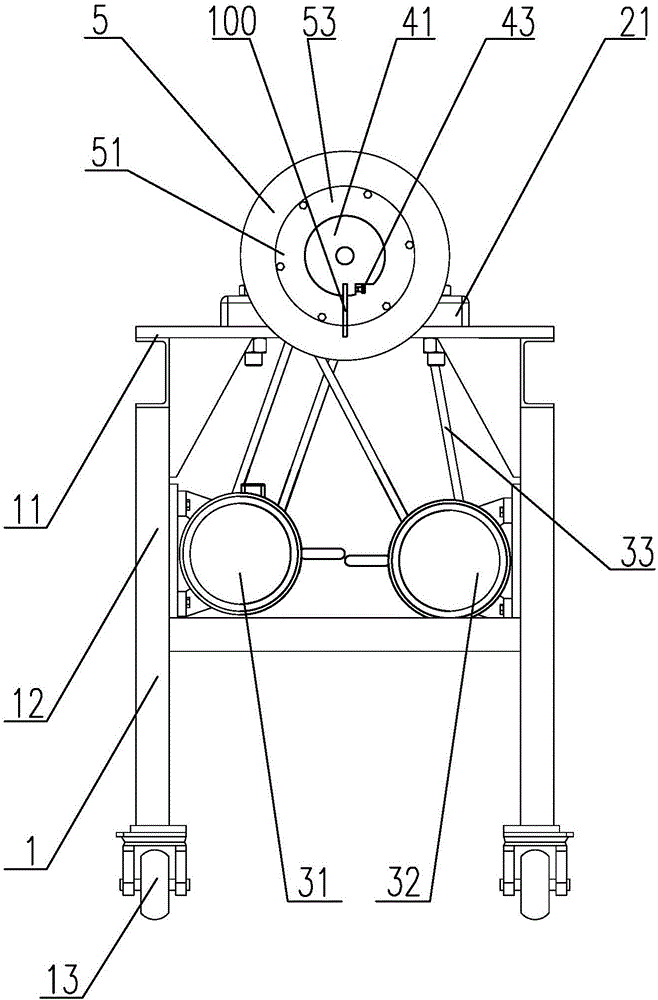

[0025] refer to Figure 1 to Figure 3 As shown, the detection device used to determine the degree of loss of aggregate to contact parts includes a bracket 1, a rotating mechanism 2, a driving mechanism 3, a clamping mechanism 4 and a lifting cylinder 5;

[0026] The support 1 includes an operating platform 11, legs 12 and rollers 13 arranged at the bottom of the legs;

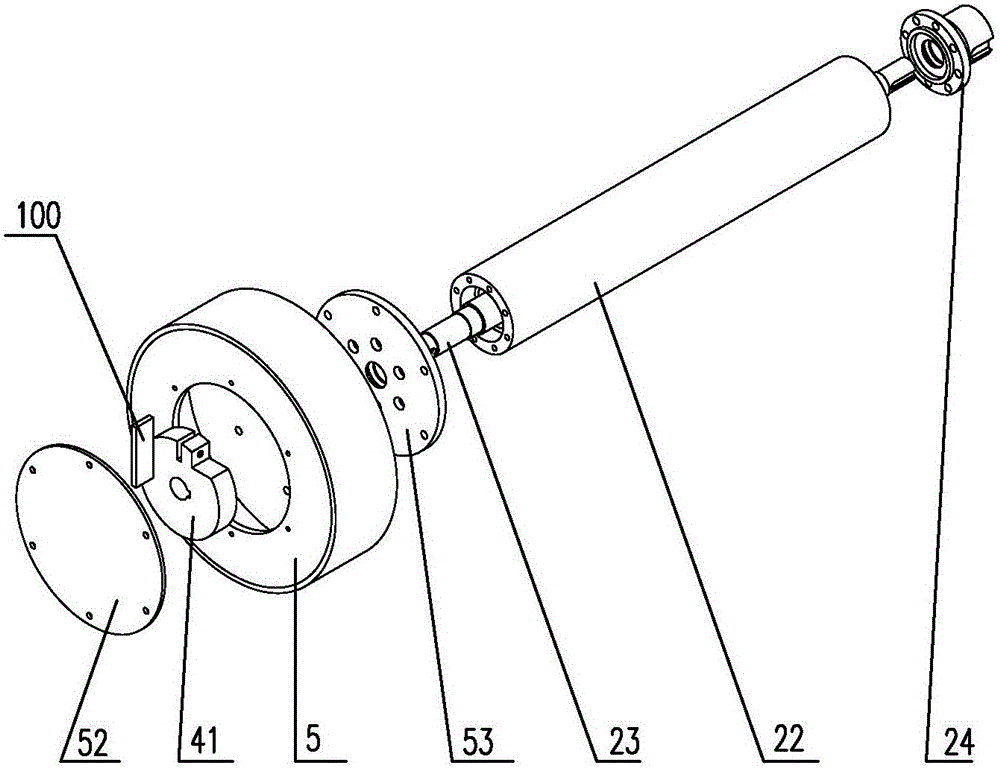

[0027] The rotating mechanism 2 is arranged on the operating platform 11 of the bracket 1, and includes a pair of bearing seats 21, a sleeve 22, a rotating shaft 23, and a bearing assembly 24. The bearing seat 21 is arranged on the operating platform 11, and the sleeve 22 is assembled in the bearing seat 21. , the rotating shaft 23 is installed in the sleeve 22, the bearing assembly 24 is arranged between the sleeve 22 and the rotating shaft 23, one end of the sleeve 22 is connected with the lifting cylinder 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com