Heat pump type drying device

A drying device and heat pump technology, applied in heating devices, heat pumps, drying, etc., can solve the problems of heat energy loss, low heat energy conversion efficiency, which can only reach about 90%, and achieve the purpose of promoting heating and drying and reducing drying energy consumption , The effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with accompanying drawing, the present invention is described in further detail.

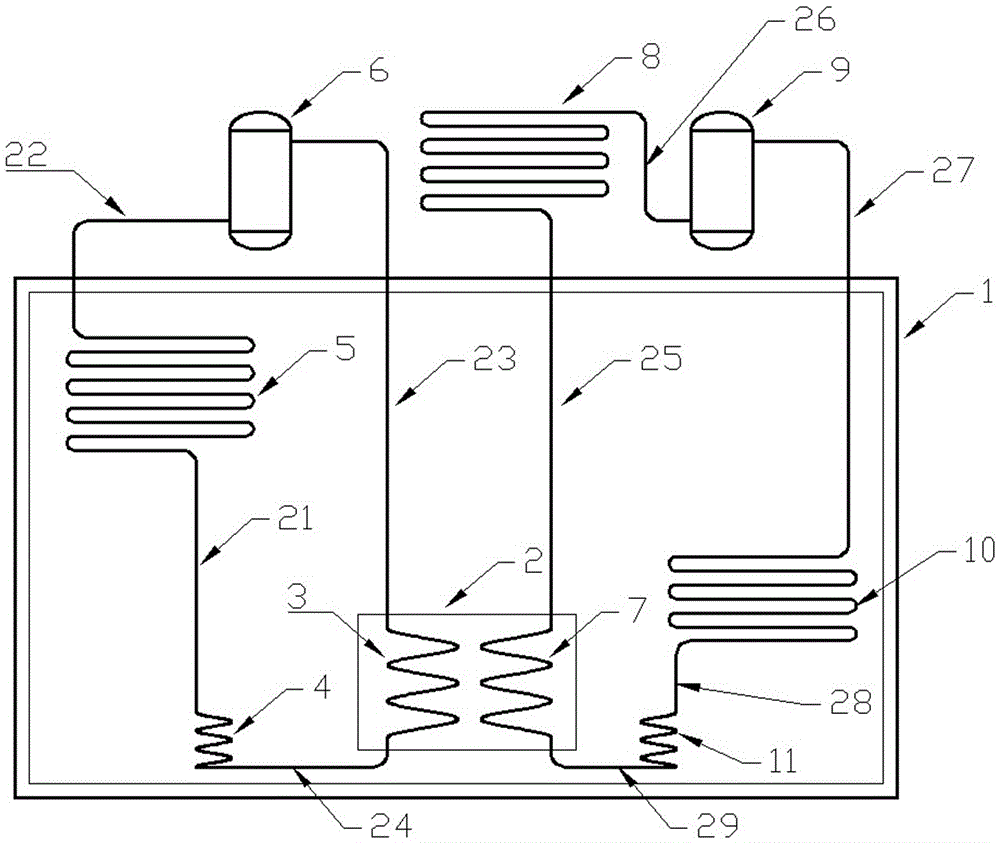

[0019] Such as figure 1 The shown heat pump drying device is isolated from the external environment by the thermal insulation enclosure 1, and the thermal insulation enclosure 1 constitutes a dry working environment, wherein there is a water tank 2, and the spiral coil tube A3 and the spiral coil tube B7 are installed in the water tank 2 and injected An appropriate amount of water submerges the spiral coil; compressor A6, spiral coil A3, capillary A4, coil A5 and pipes 21, 22, 23, and 24 form a group A heat pump cycle dehumidification system; compressor B9, coil B10, capillary B11, The spiral coil tube B7, the outer coil tube 8 and the pipelines 25, 26, 27, 28, 29 form a group B heat pump circulation heating system. The A and B systems work alternately to realize the heat pump cooling in the dry environment to condense and discharge the water vapor, and the heat pump h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com