Electric heating module, heating floor, installation method for heating floor and heating roof

An installation method and electric heating technology, applied in heating methods, electric heating systems, household heating and other directions, can solve the problems of complex slotting process, slow heating, floor cracking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the scope of the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the unspecified implementation conditions are usually the conditions in routine experiments.

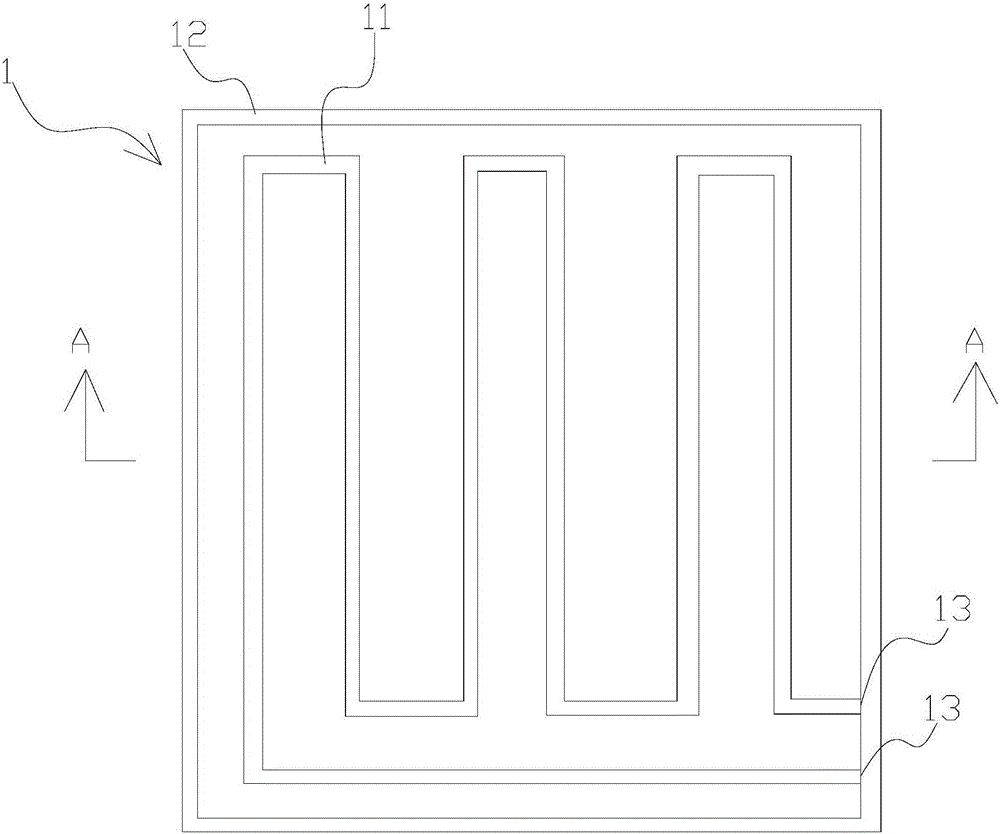

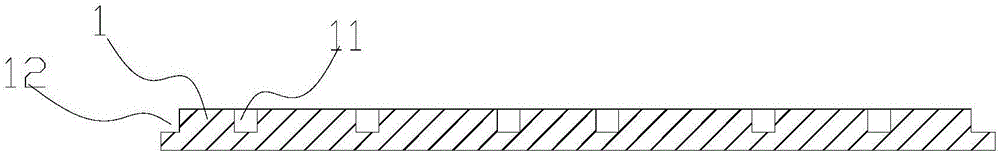

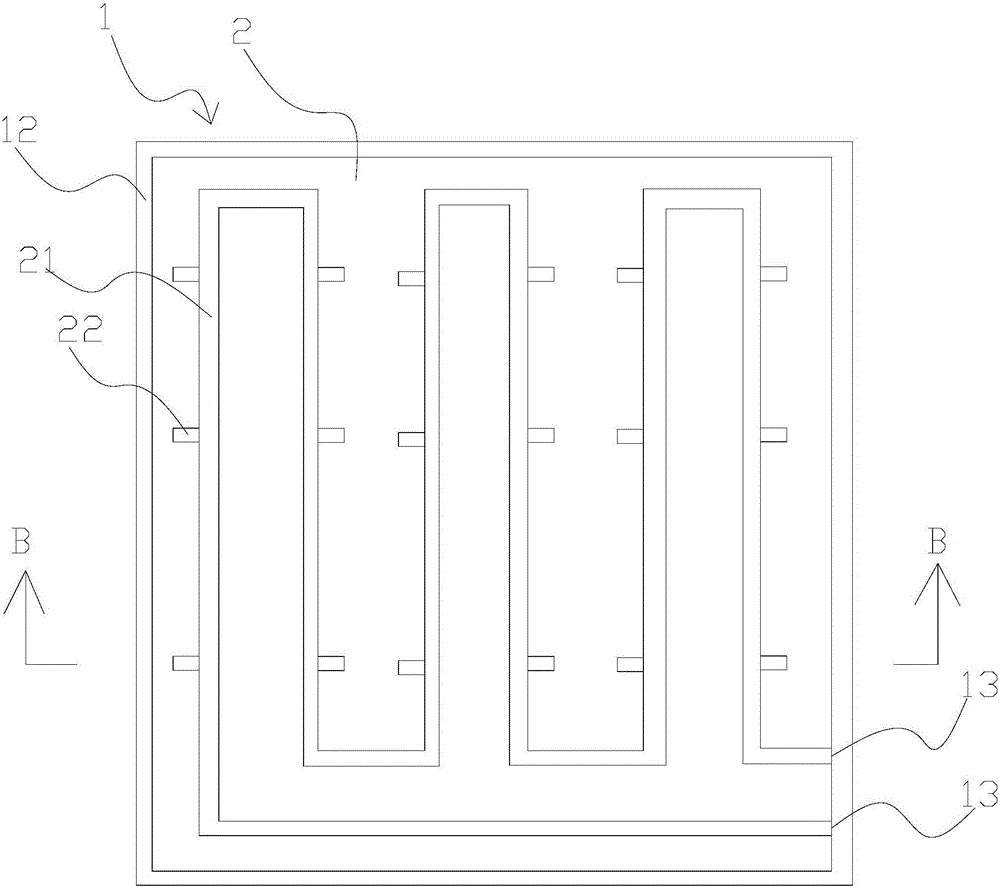

[0044] Such as Figure 1~6 As shown, the present invention provides an electric heating module, comprising figure 1 As shown in the heat insulation board 1 , the upper surface of the heat insulation board 1 is provided with a wiring groove 11 with a notch upward, and the wiring groove 11 has multiple bends on the heat insulation board 1 , The wiring trough 11 is arranged in a serpentine shape or a loop on the upper surface of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com