A quantitative filling device

A technology of quantitative filling and housing, which is applied in the direction of quantitative devices, distribution devices, lubricating parts, etc., can solve the problems of inability to achieve quantitative filling, poor adjustment, and inaccurate filling volume, and achieve accurate and reliable adjustment , easy to adjust, precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

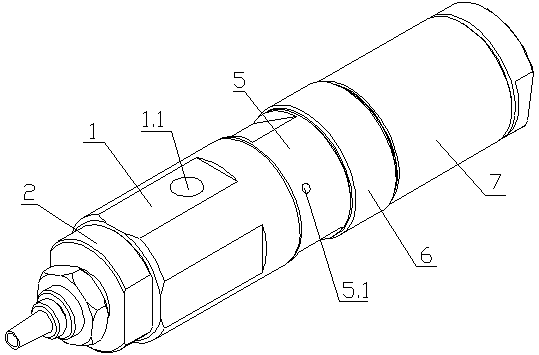

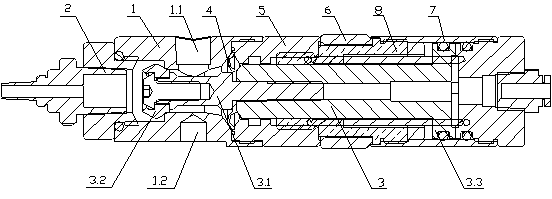

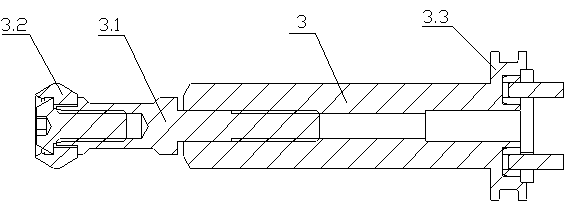

[0022] see Figure 1~3 , a quantitative filling device related to the present invention, said device includes an upper casing 1, an inlet hole 1.1 is arranged on the casing wall of said upper casing 1, and a piston is plugged into said upper casing 1. The plunger rod 3.1 driven by the rod 3, the head of the plunger rod 3.1 is equipped with a sealing sleeve 3.2, and the sealing sleeve 3.2 is pressed on the convex ring of the inner wall of the upper housing 1, and the upper housing 1 One end is installed with a dispensing head 2, the other end of the upper shell 1 is pressed with a barrier ring 4, and the barrier ring 4 is set on the plunger rod 3.1, and the barrier ring 4 is made of flexible material; the upper shell Body 1, plunger rod 3.1, sealing sleeve 3.2 and barrier ring 4 form a sealed cavity, and the above-mentioned inlet hole 1.1 communicates with the sealed cavity;

[0023] When in use, the lubricating oil waiting to be filled enters the cavity between the upper hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com