System and process for coal seam permeability improvement by inducing hole drilling extraction later-period gas burning explosion

A gas and coal seam technology, which is applied to the field of anti-reflection gas extraction in coal seams, can solve the problems of rapid reduction of the extraction concentration and difficulty in gas extraction, and achieves the effects of large fracturing energy, long extraction period and simple process structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

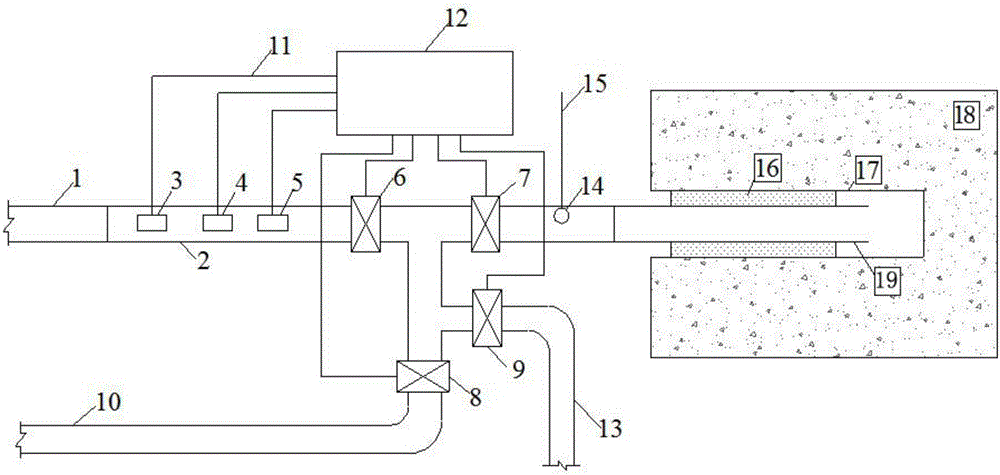

[0028] After constructing an underground coal seam gas drainage hole with a diameter of 89mm and a depth of 10m, a connecting pipe 2 is connected to the front section of the hole sealing, and a temperature sensor 3, a methane sensor 4, a carbon monoxide sensor 5, a solenoid valve I6, and a solenoid valve II7 are arranged on the connecting pipe 2 , electric spark igniter 14, the middle section of connecting pipe 2 is connected with water pipe 10, is provided with solenoid valve III8 on water pipe 10, and the right end of connecting pipe 2 is connected with sealed gas drainage borehole 17, and the front end of borehole There is a sealing section, solenoid valve I6, solenoid valve II7, solenoid valve III8, temperature sensor 3, methane sensor 4, carbon monoxide sensor 5 are connected to the intelligent controller 12 through the connection line 10, and the electric spark igniter 14 is connected to the outside through the wire 15. connected to the power switch.

[0029] Intelligent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com