Method for improving anti-seismic property of RC Z-shaped cross section column frame node

A technology for seismic performance and column joints is applied in the field of high-strength stirrup-constrained polyvinyl alcohol fiber cement-based composite material reinforcement, which can solve the problems of limiting the total application height of special-shaped column structures, difficulty in concrete vibrating and compacting, serious earthquake damage, etc. Good crack dispersion ability, improve shear deformation and energy dissipation ability, delay the effect of main oblique crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

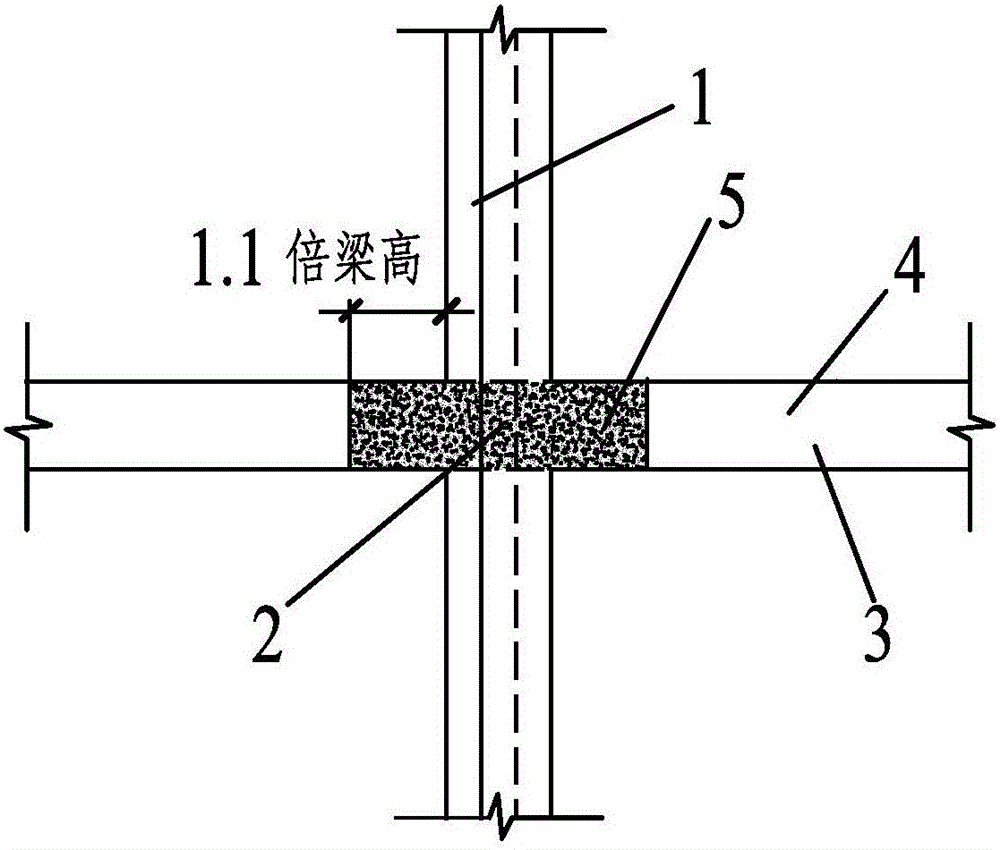

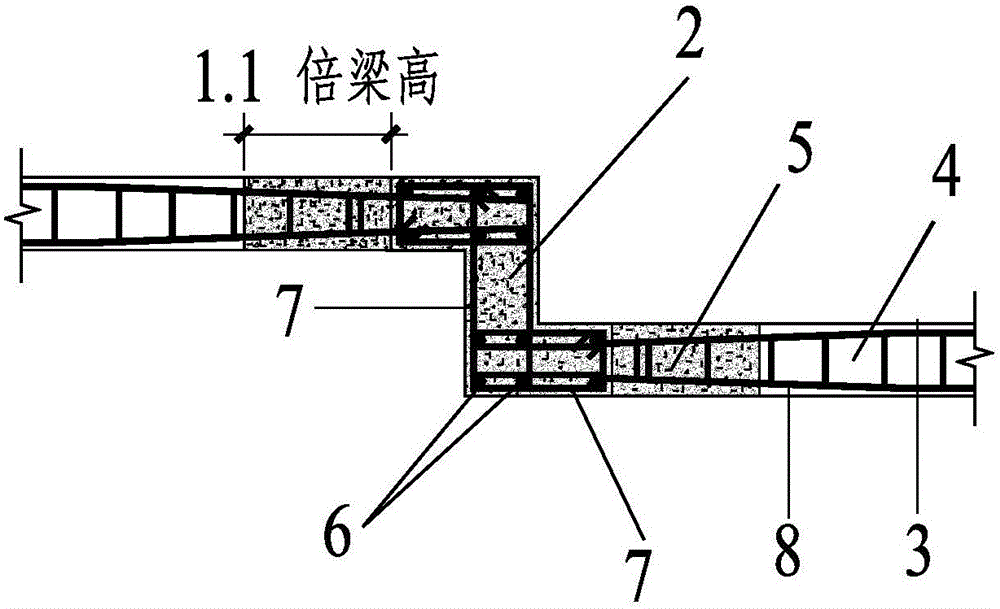

[0015] refer to figure 1 with figure 2 , a method for improving the seismic performance of RC Z-shaped column frame joints, the Z-shaped column frame joints include Z-shaped columns 1 and frame beams 3, the junction of the Z-shaped columns 1 and frame beams 3 is the joint core area 2, in PAV-ECC materials are poured into the core area 2 of the Z-shaped column node and adjacent frame beams within a range of 1.1 times the beam height to form a composite area 5, and concrete is poured in the Z-shaped column 1 and the frame beams 3 connected on both sides, and the composite The distance between the area and the concrete area 4 poured in the frame beam is 1.1 times the beam height from the beam-column interface.

[0016] PVA-ECC reinforced concrete Z-shaped column frame joints reinforced with high-strength stirrups are used to connect reinforced concrete special-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com